Manufacturing technology of stainless steel enamelled cup

A production process and stainless steel technology, applied in the field of cups, can solve the problems of stainless steel cups that are not easy to clean, not heat preservation, and not resistant to falling, etc., and achieve the effect of beautiful appearance, strong safety performance, and overcoming defects.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

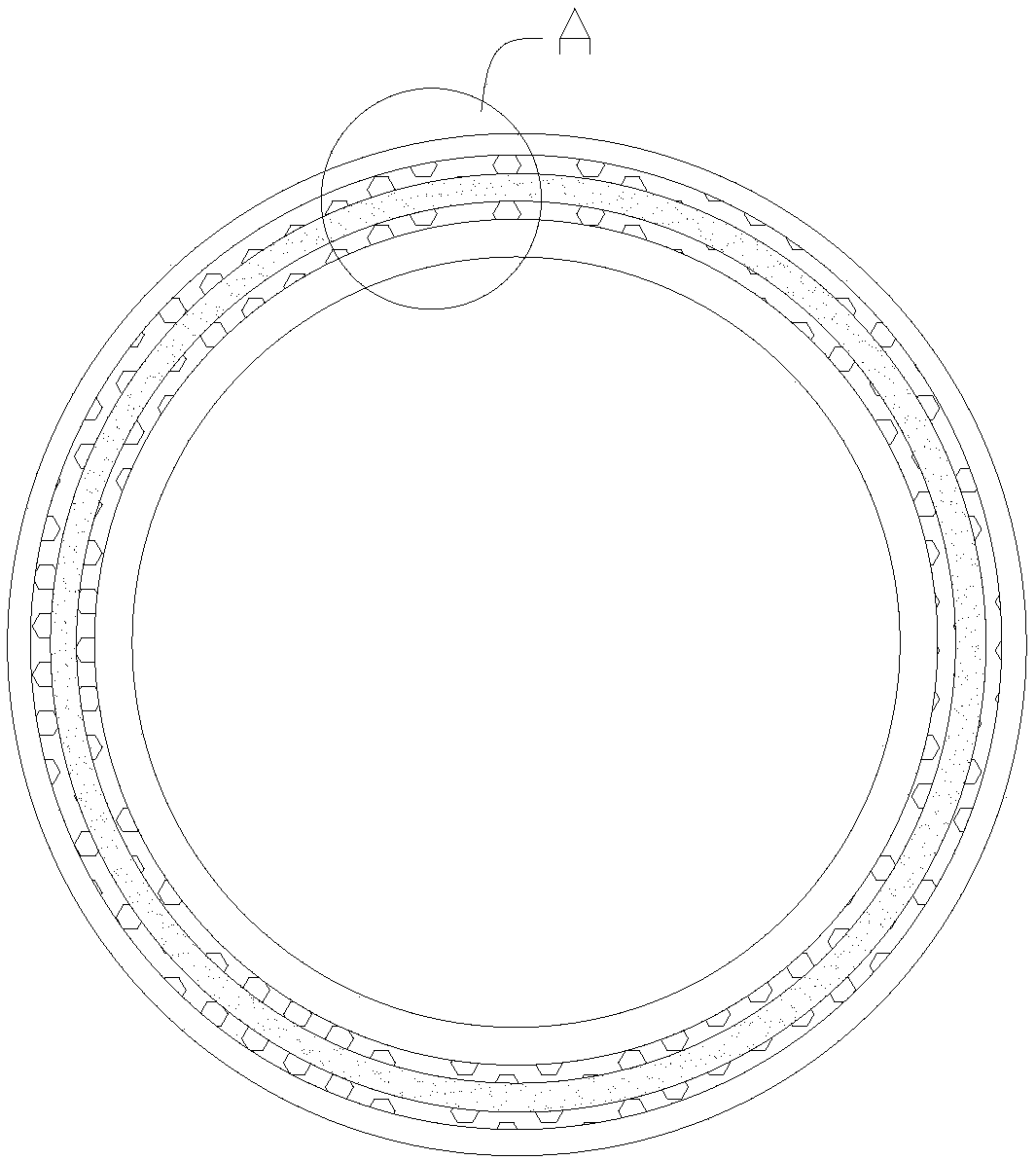

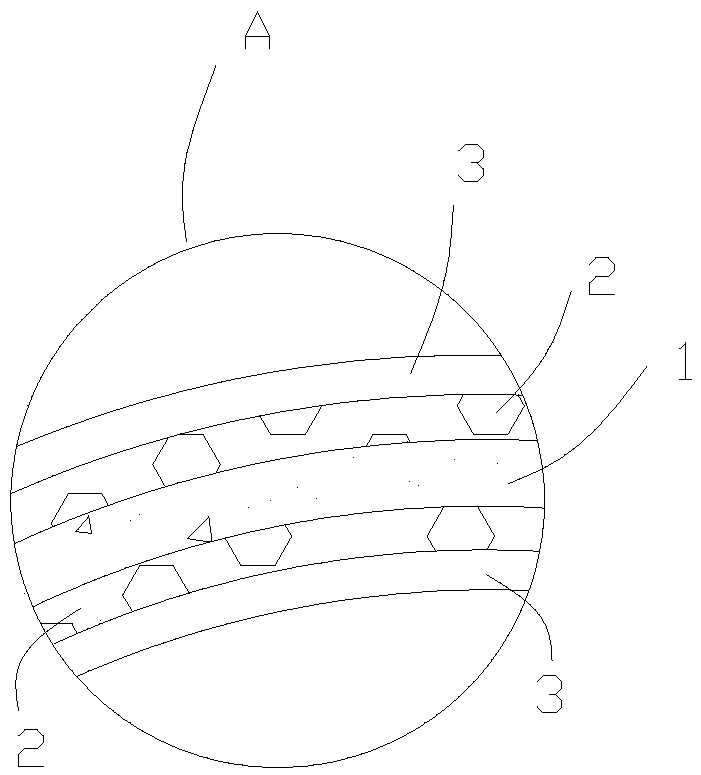

[0024] see Figure 1-2 , a stainless steel enamel cup manufacturing process is characterized in that: comprising the steps:

[0025] S1: made of stainless steel cup;

[0026] S2: Degreasing the inner and outer surfaces of the cup prepared in step S1;

[0027] S3: Sandblasting the internal and external surfaces of the cup after degreasing;

[0028] S4: Spray or enamel the first layer of nano-enamel glaze on the inner and outer surfaces of the cup after sandblasting;

[0029] S5: primary sintering;

[0030] S6: cooling;

[0031] S7: Spray or enamel the second layer of nano-enamel glaze on the inner and outer surfaces of the cup;

[0032] S8: secondary sintering;

[0033] Wherein, the nano-enamel glaze comprises the following components by weight: 70-75 parts of traditional enamel glaze, 8-15 parts of nano-particle powder, 2-5 parts of nano-fluorite powder, 2-5 parts of nano-fiber powder, and 2-5 parts of nano-glass powder. 5 servings.

[0034] The nano-enamel glaze compr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com