Integrated two-stage indirect evaporative cooling water chilling unit

A chiller, evaporative cooling technology, applied in water shower coolers, heating methods, space heating and ventilation, etc., can solve the problems of large power consumption and high operation and maintenance costs for cold water production, and reduce fan energy consumption and structure. The effect of compactness and increased attachment area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments.

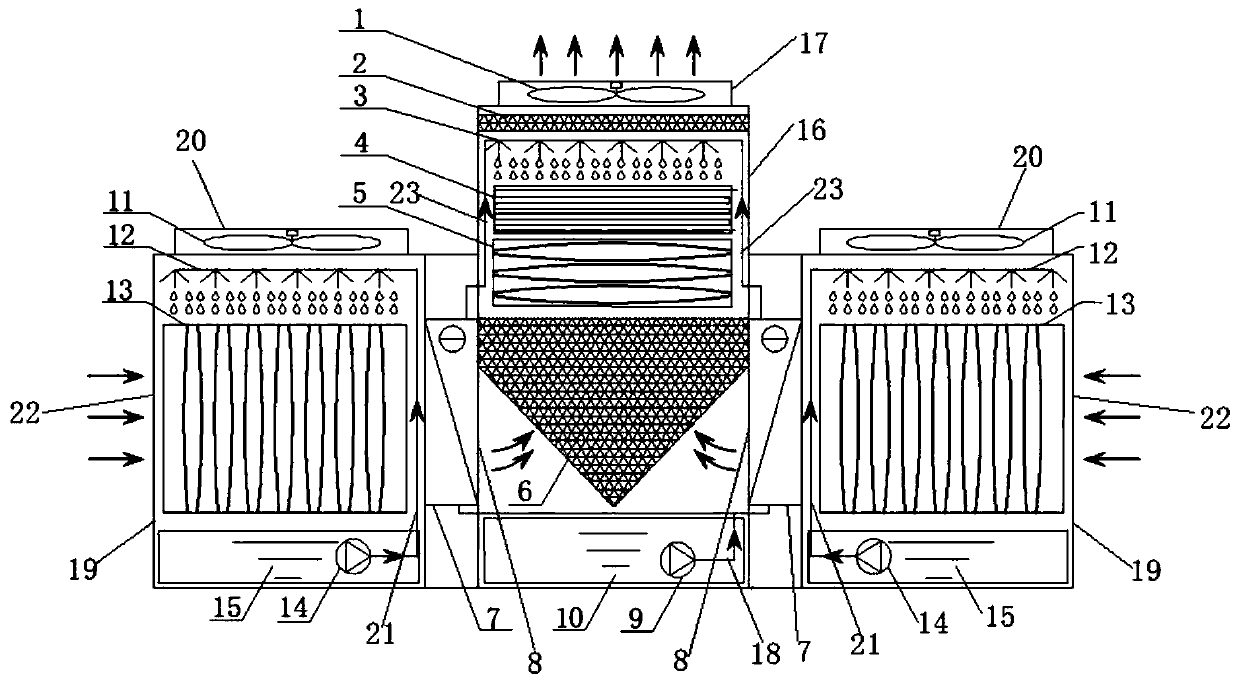

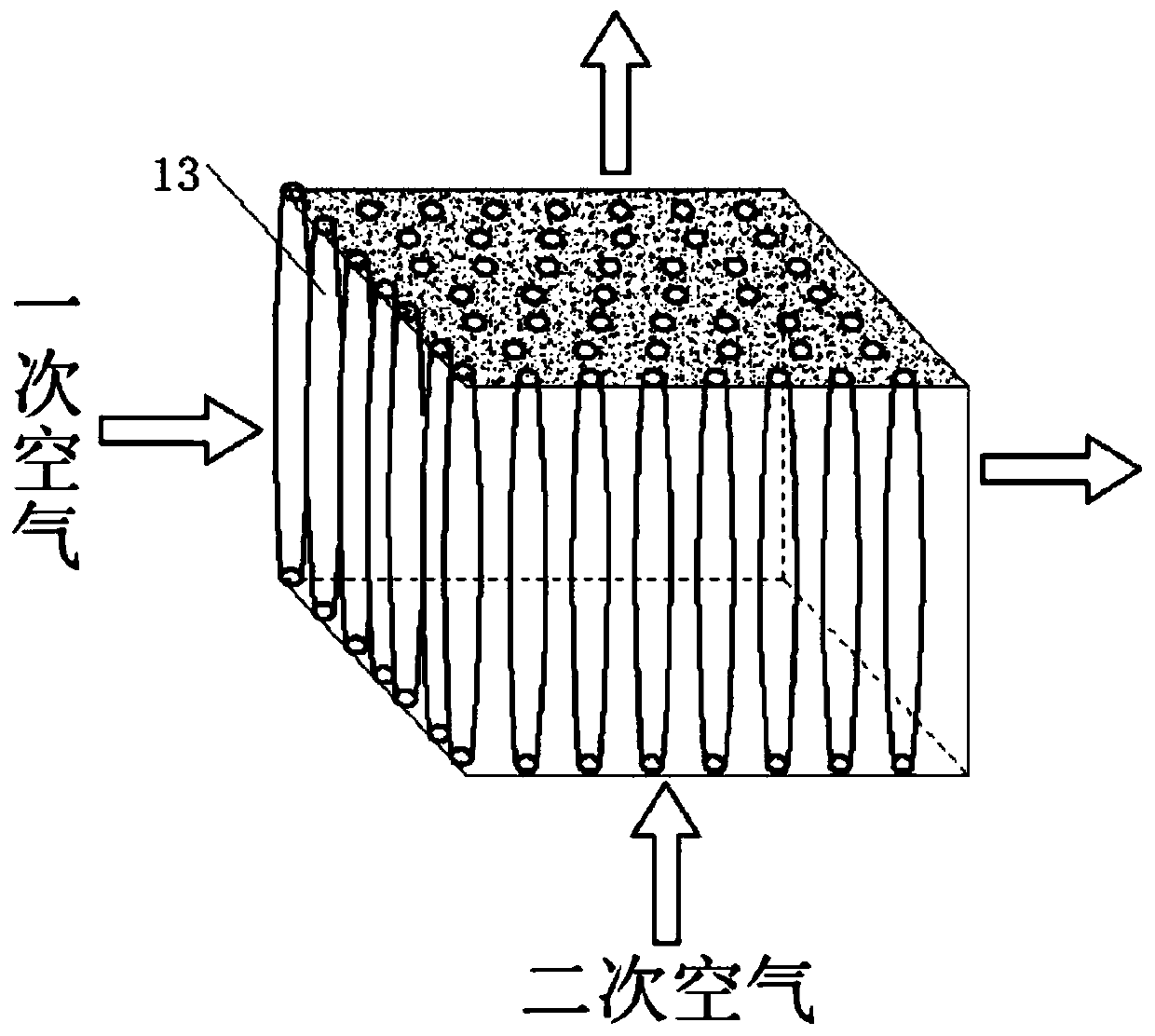

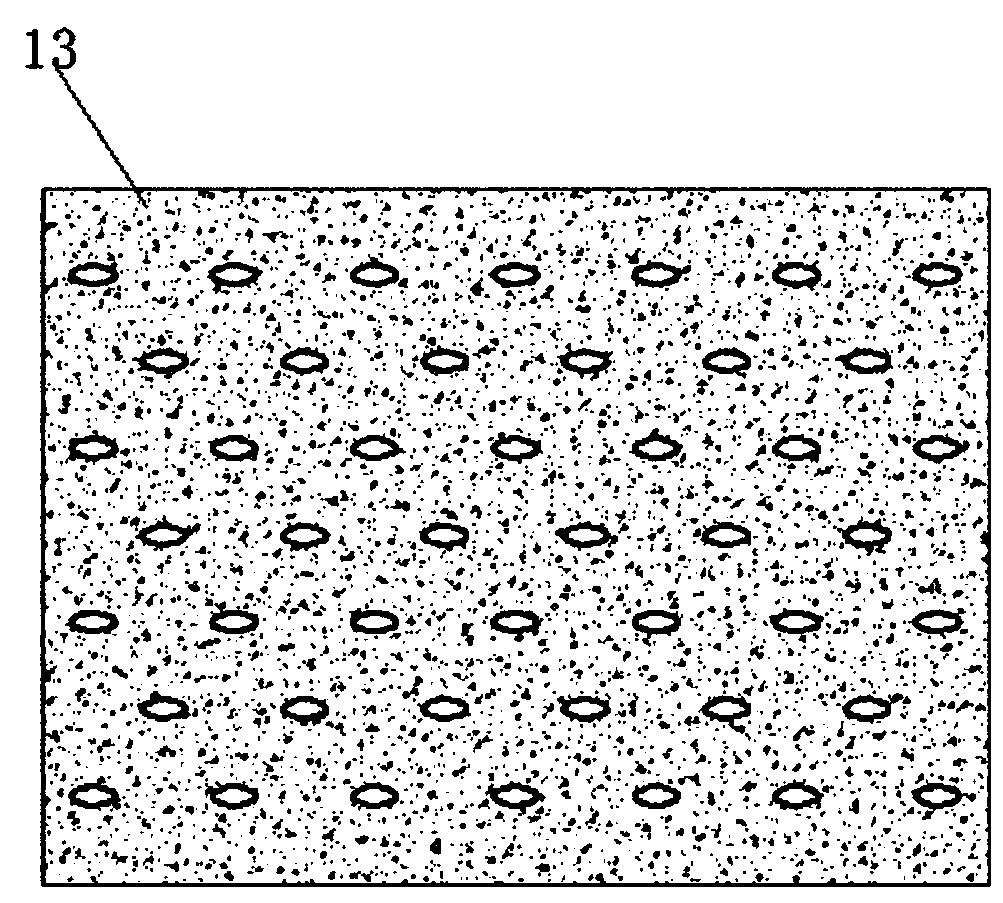

[0026] The integrated two-stage indirect evaporative cooling chiller of the present invention has a structure such as figure 1 As shown, there are horizontal tube olive tube type direct evaporative cooling units and vertical tube olive tube type indirect evaporative cooling units symmetrically arranged on the left and right sides of the horizontal tube olive tube type direct evaporative cooling unit, horizontal tube olive tube type direct evaporative cooling units Two air inlets 8 are arranged symmetrically on the left and right sides of the unit, and the two air inlets 8 communicate with the primary air outlets of the standpipe olive tube type indirect evaporative cooling unit on the corresponding side respectively.

[0027] There is also a surface cooler 7 between the two air inlets 8 and the primary air outlet of the vertical tube olive tu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com