Coating production safety smart patrolling robot, system and method

An intelligent inspection and robot technology, applied in the field of inspection, can solve the problems of serious danger, consuming a lot of human resources, and increasing costs, so as to reduce the use of manpower and ensure safety.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

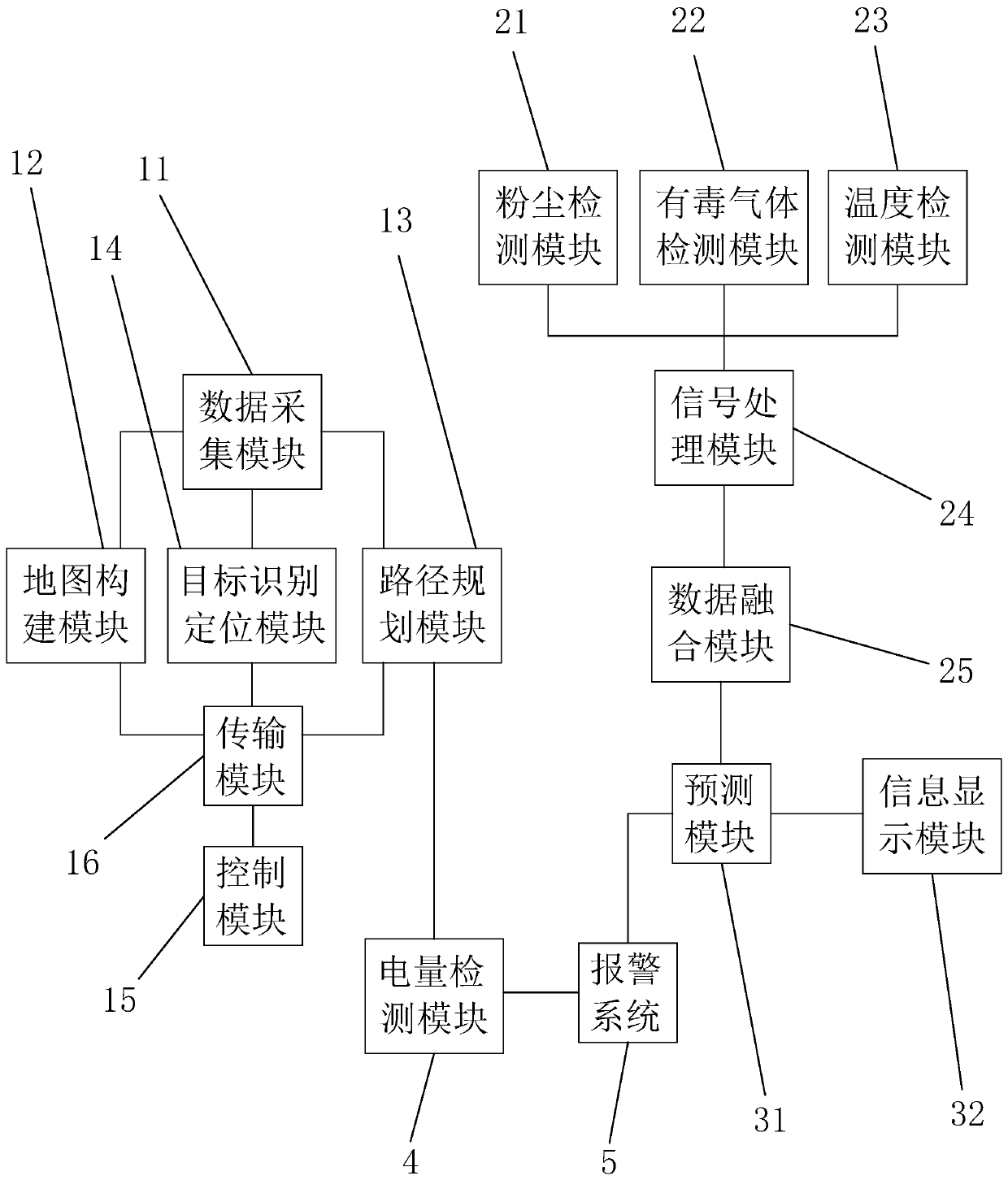

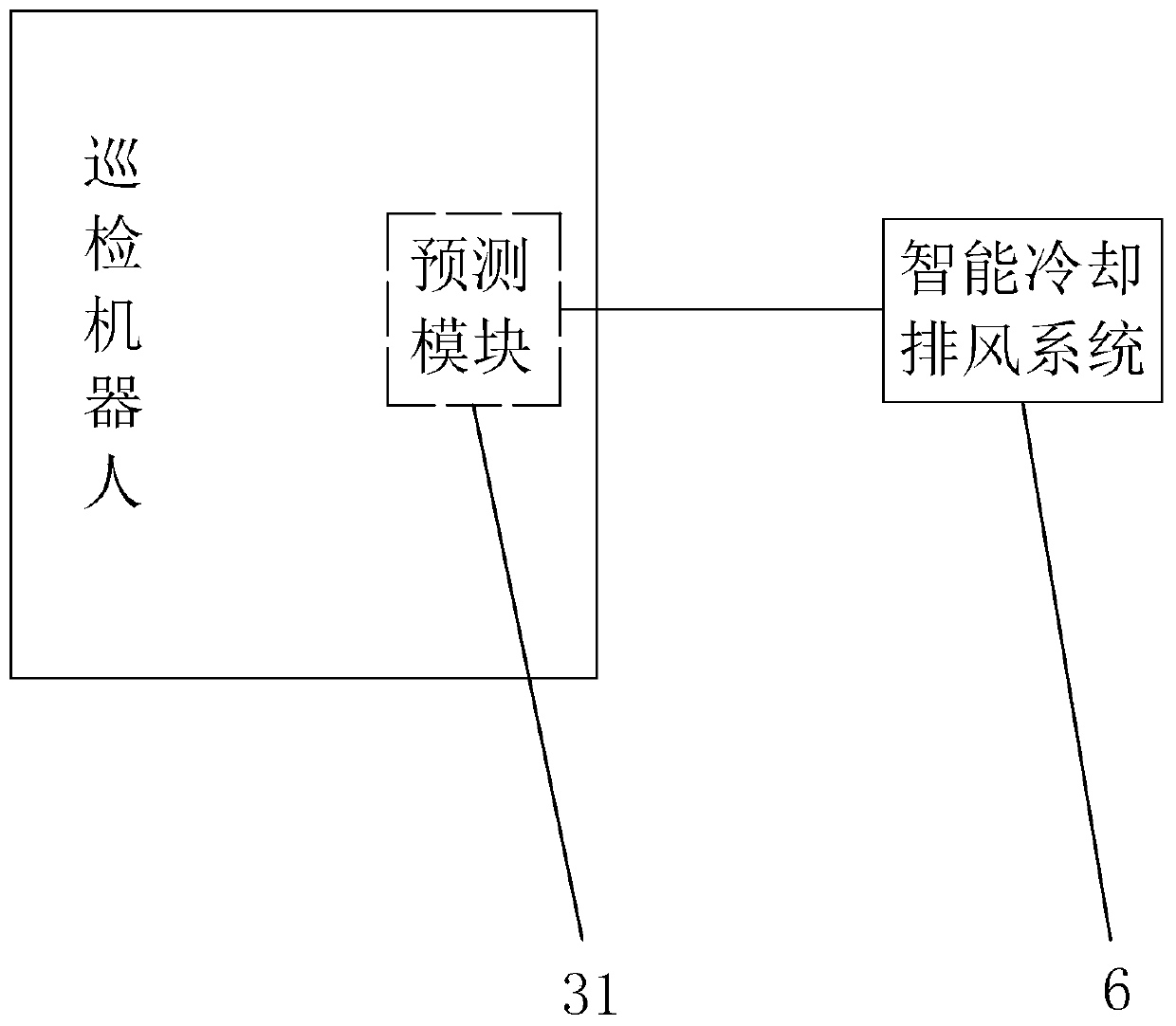

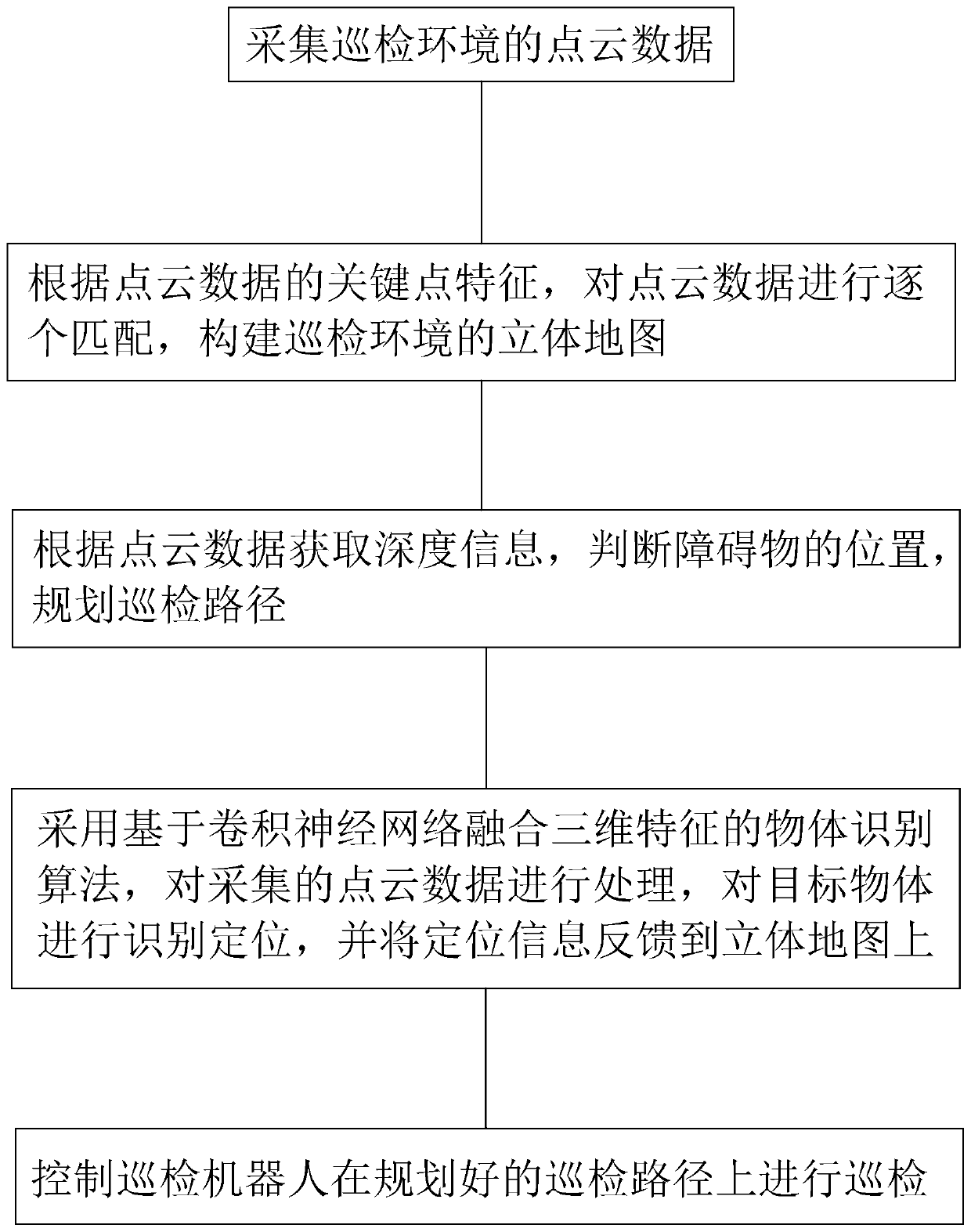

Method used

Image

Examples

Embodiment Construction

[0026] Paint production industry is a kind of chemical industry. Paint production belongs to the production process of hazardous chemicals. Most of the raw materials are various dangerous chemicals with various types and different chemical properties. Most of them are flammable and toxic, and the dangerous nature is serious; and in In the process of chemical production, certain substances tend to generate heat due to the physical, chemical and biochemical reactions that occur inside. The accumulation of heat makes the temperature of combustibles higher and higher. When the temperature reaches a certain level, the combustible gas or toxic gas just reaches When the concentration is certain, combustion or explosion accidents will occur, which reflects the unsafety of coating production; operators must stay by the equipment when performing manual operations. The hidden dangers cannot be avoided even when they break out, threatening the safety of operators; a large amount of mineral...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com