Easy-to-start thin motor

A thin motor and base technology, applied in the field of motors, can solve the problems of inapplicability, magnetic flux leakage, etc., achieve good practicability and improve the effect of magnetic attraction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

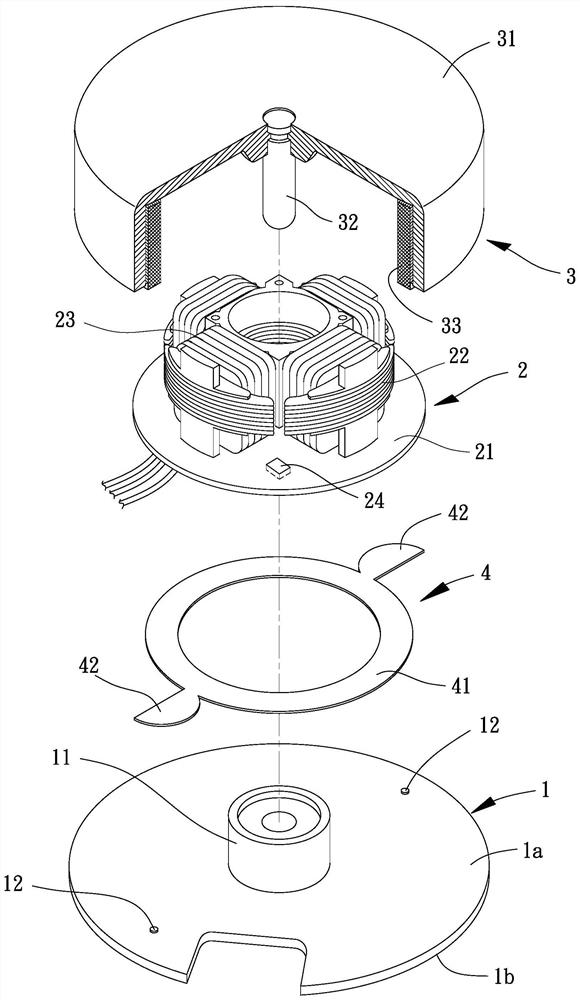

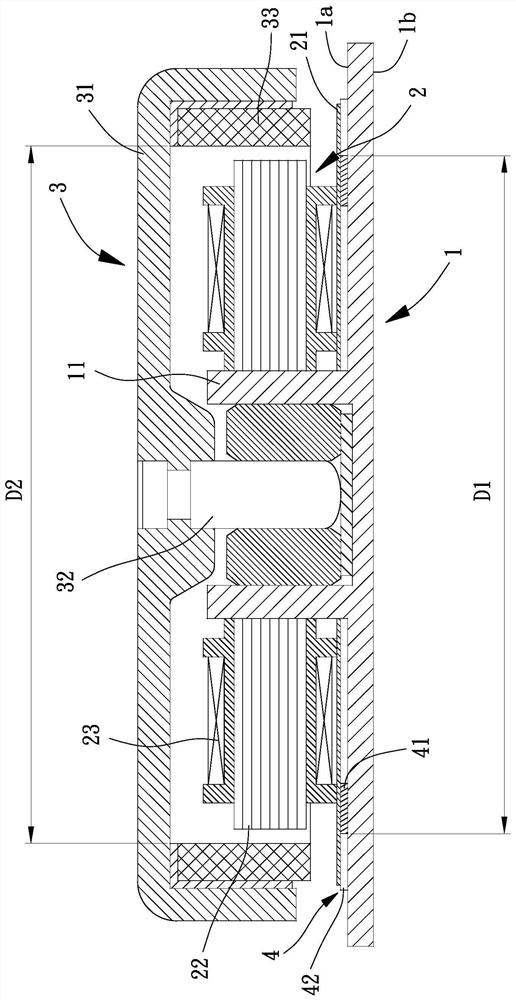

[0068] Please refer to figure 2 , which is the first embodiment of the easy-to-start thin motor of the present invention, the easy-to-start thin motor generally includes a base 1, and a stator 2, a rotor 3 and a magnetic attraction set on the base 1 Ring 4.

[0069] Please refer to figure 2 , image 3 , the base 1 has an opposite inner surface 1a and an outer surface 1b, the inner surface 1a of the base 1 is protruded with a shaft tube 11; in this embodiment, the shaft tube 11 is integrated with the inner surface 1a Therefore, the base 1 can be integrally injection-molded with plastic material to improve the manufacturing convenience of the base 1 . In addition, the base 1 can also be provided with an anti-rotation part 12 to prevent the magnetic ring 4 from rotating on the base 1, so as to improve the positioning effect of the magnetic ring 4; the anti-rotation part 12 can For example, two bumps on the inner surface 1a, or other equivalent structures, the present invent...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com