Sink dishwasher

A technology for dishwashers and dishwasher inner tanks, which is applied to tableware washing machines/rinsing machines, tableware washing machines/rinsing and rinsing machine parts, cleaning equipment, etc., and can solve the problem of inability to achieve water mist combination and spray port coverage Small range, affecting the cleaning effect and other problems, to achieve the effect of shortening the washing time, increasing the water pressure, and improving the washing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

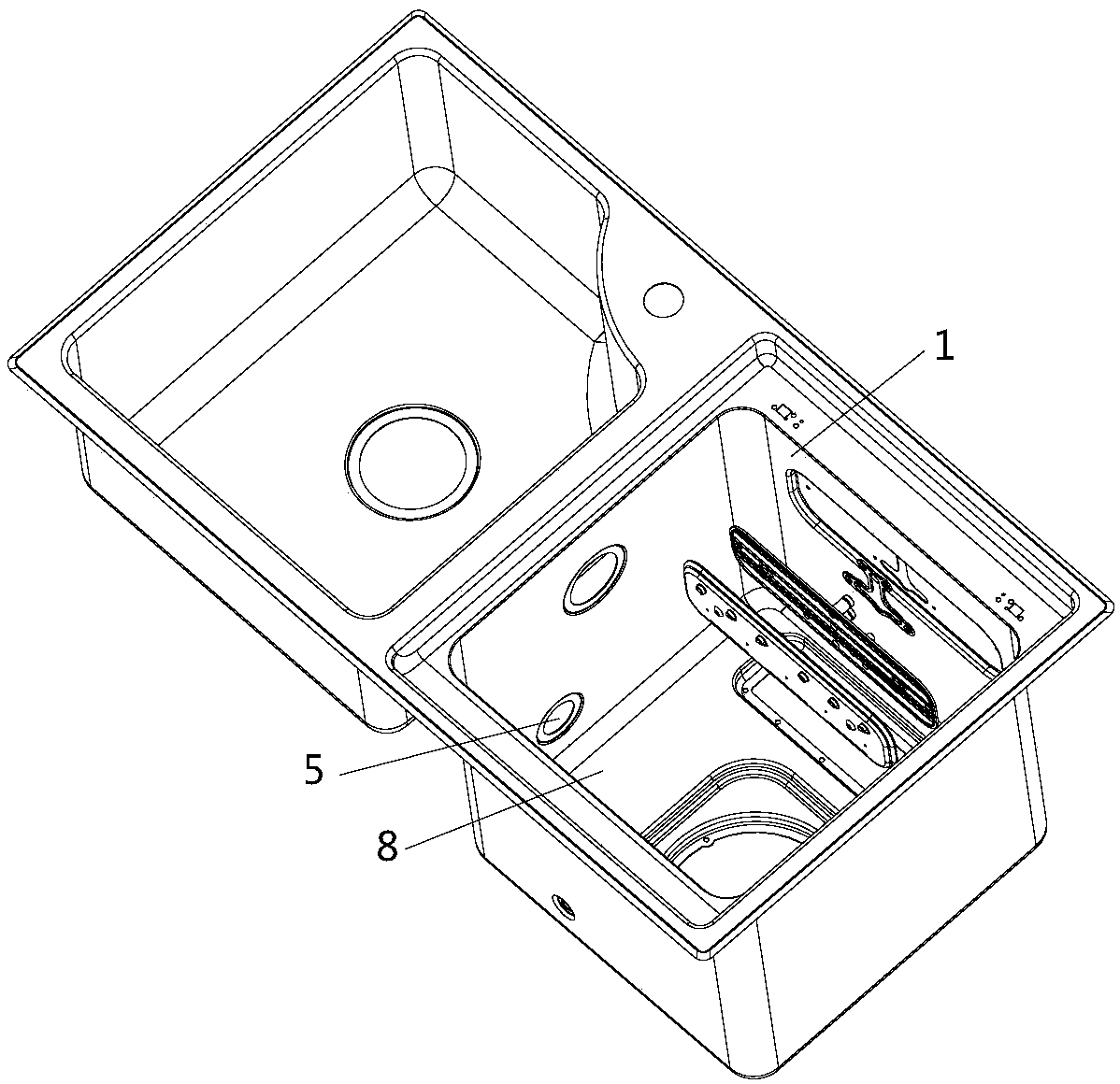

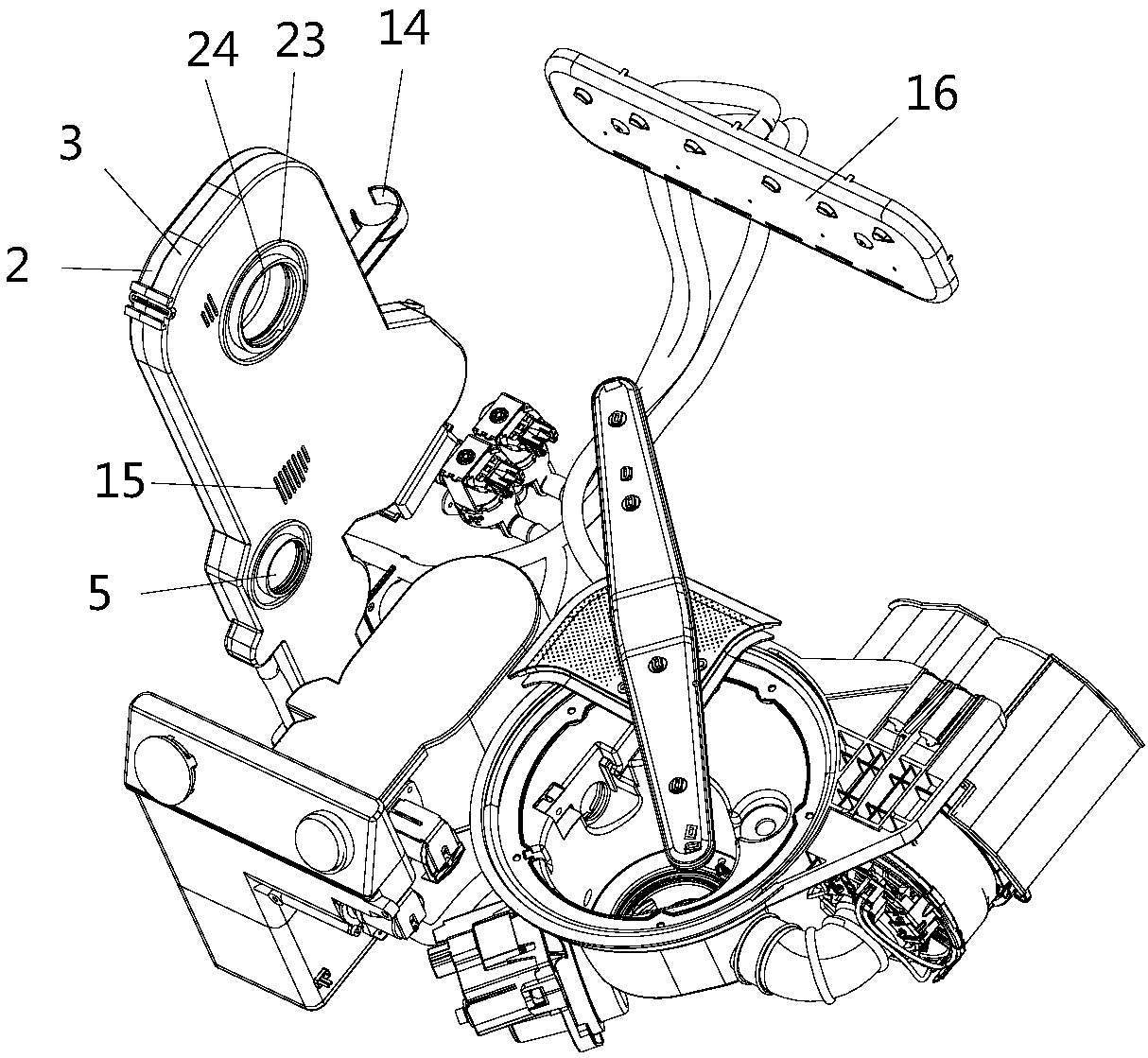

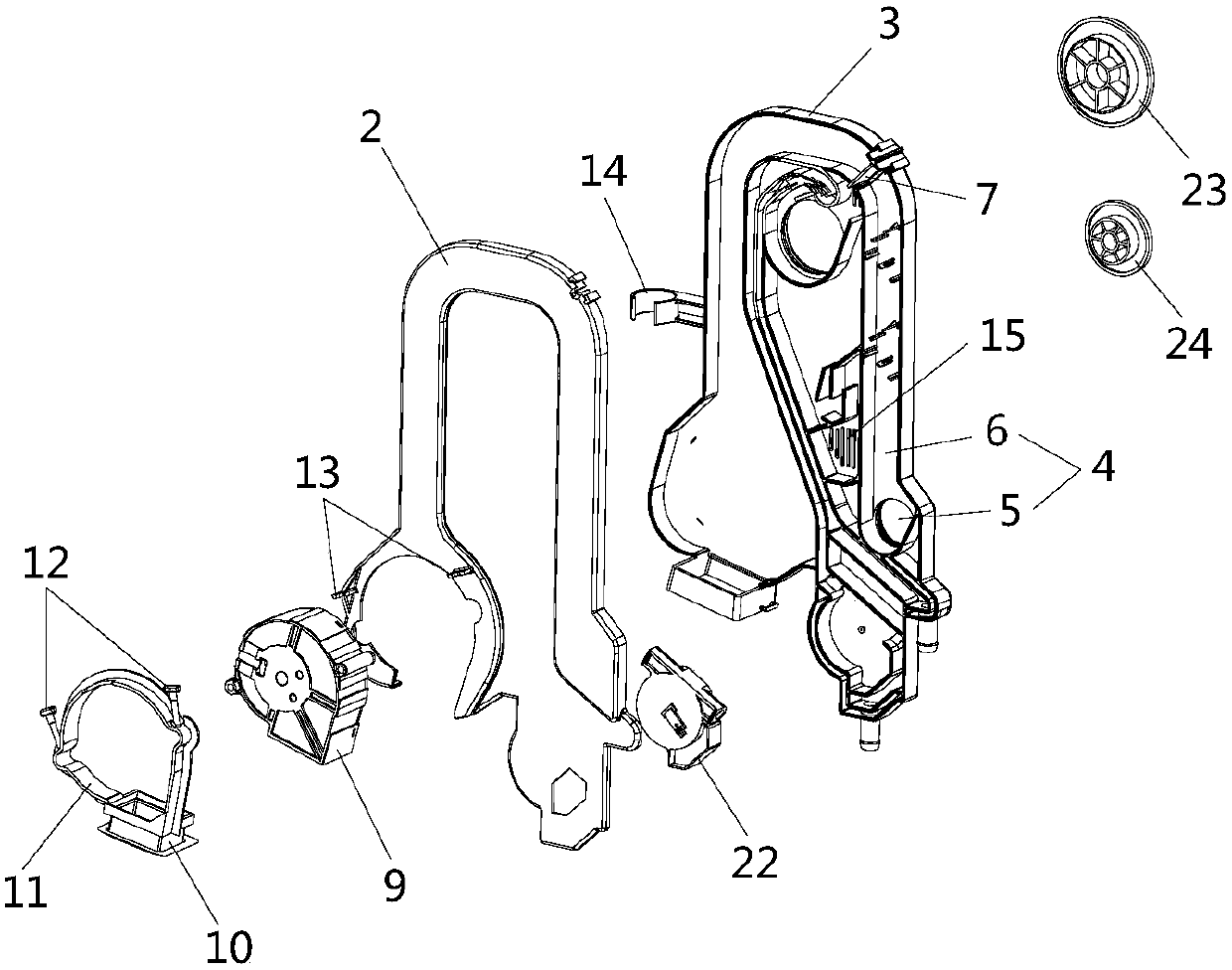

[0056] like Figure 1 to Figure 5 As shown, the respirator of the sink dishwasher in this embodiment includes a respirator base 3 connected to the outside of the tank side wall 1, a respirator shell 2 used in conjunction with the respirator base 3, and further includes a respirator set on the The respirator fixing unit 23 and the exhaust outlet fixing unit 24 of the tank side wall 1; the ventilation unit 4 includes the air duct inlet 5 arranged on the respirator base 3 and the air duct connected to the air duct inlet 5 6.

[0057] like Figure 4 As shown, one side of the respirator mouth and the air duct air inlet 5 is connected to the inside of the washing chamber, and the other side is an integrated cavity formed by the respirator and the air duct 6 . This integrated cavity is divided into two parts, the respirator cavity is located in the middle, and the cavity of the air duct 6 is located at the periphery; the respirator base 3 of the present invention is also provided w...

Embodiment 2

[0065] like Figure 1 to Figure 5 As shown, this embodiment is a further limitation of the first embodiment above, and the vibration damping unit 11 described in this embodiment is made of rubber.

Embodiment 3

[0067] like Figure 1 to Figure 5 As shown, this embodiment is a further limitation of the first or second embodiment above. The sink dishwasher described in this embodiment includes a static spray arm 16, which is arranged on the side wall 1 of the tank body. The static spray arm 16 It includes a pressurization unit 17 for spraying high-pressure water mist, a steam unit 18 for spraying high-temperature steam, and an overflow port 19, which makes the cleaning process more thorough under the action of high-pressure spray and high-temperature steam, and the setting of the overflow port 19 ensures that the inside of the dishwasher is Bile 8 water level for safety.

[0068] Furthermore, the static spray arm 16 includes at least one set of spray units 20 for spraying spray water, and the spray unit 20 includes at least two spray holes 21, and each spray hole 21 sprays in a different direction , Multi-angle spray cleaning avoids the existence of cleaning dead ends, improves the was...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com