Spraying system for sink dishwasher and sink dishwasher with spraying system

A technology of a spray system and a dishwasher, which is applied to the washing machine/washing machine for tableware, the parts of the washing machine/rinsing machine for tableware, household appliances, etc. , the loss of cleaning water and other problems, to achieve the effect of shortening the washing time, alleviating the vibration, and increasing the injection pressure.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

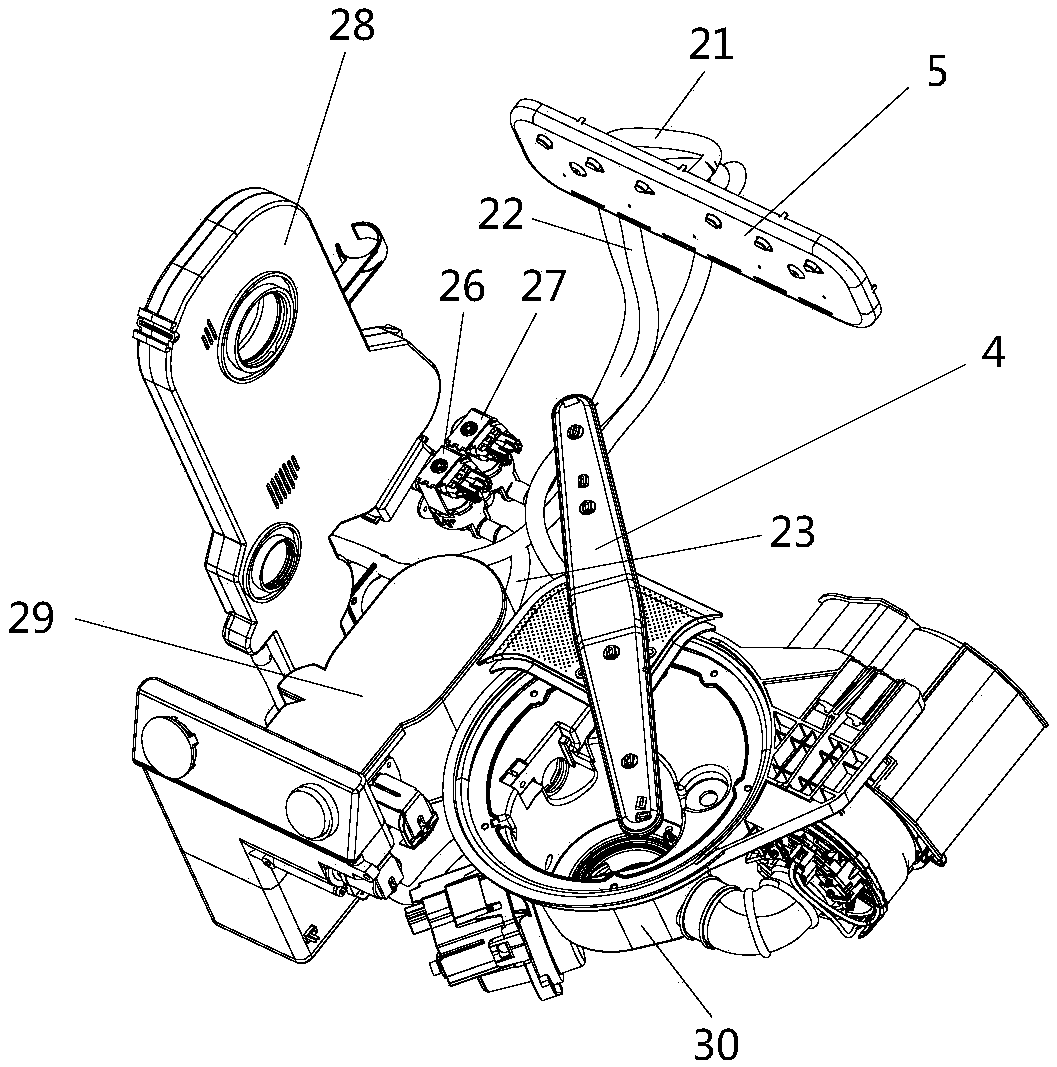

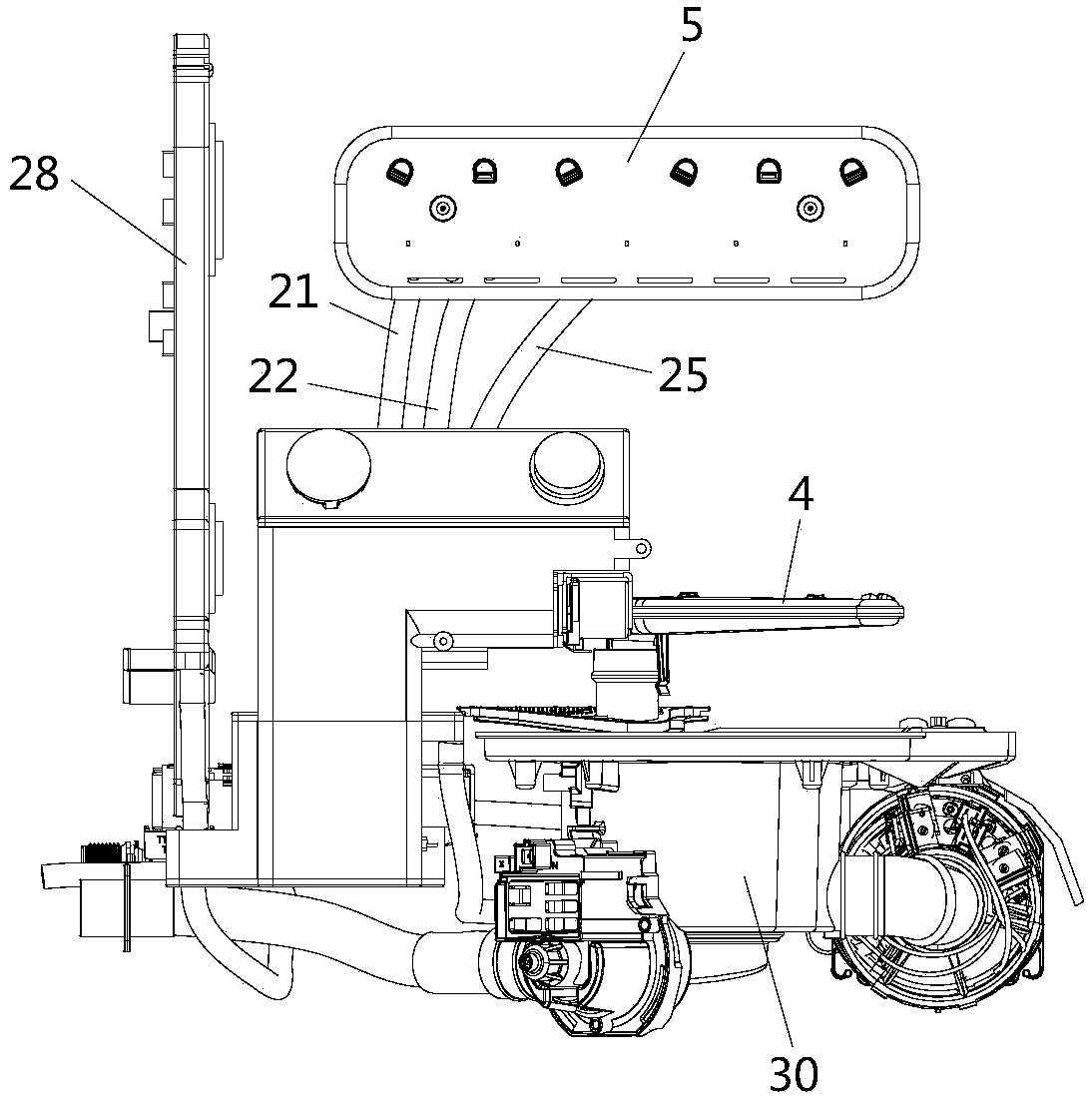

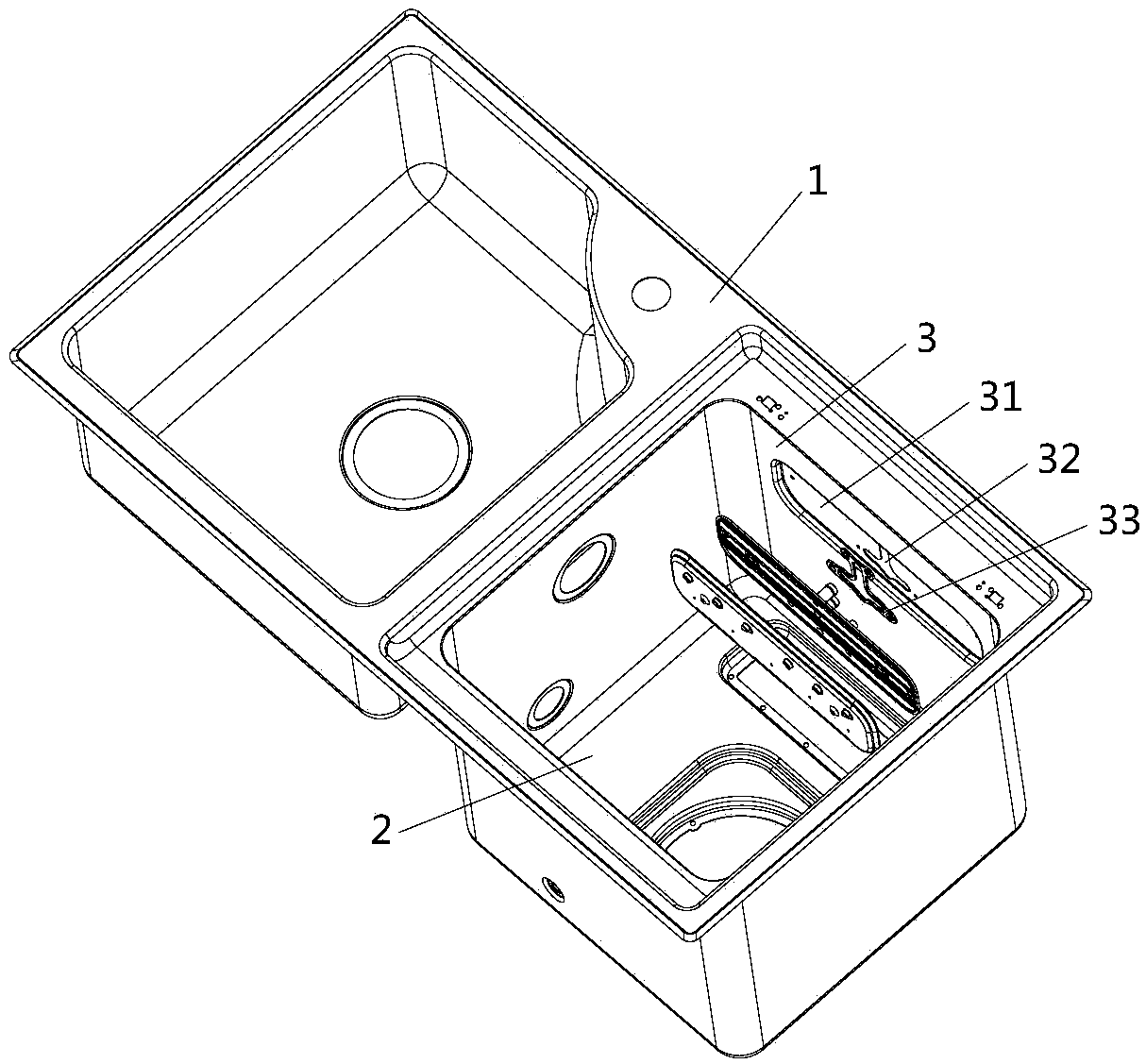

[0060] Such as Figure 1 to Figure 8 As shown, a spray system of a sink dishwasher in the present invention includes a movable spray arm 4, which is rotatably arranged at the bottom 2 of the tank body of a sink dishwasher 1; a static spray arm 5, which is arranged at the sink for washing dishes The tank side wall 3 of the machine 1; the static spray arm 5 is also provided with a booster unit 6 for spraying high-pressure water mist, a steam unit 7 for spraying high-temperature steam, and an overflow port 8. Further, the water tank of the present invention Dishwasher 1 also includes a dish rack, said dish rack is a dish rack structure with at least two layers, said movable spray arm 4 is provided with corresponding washing water spray holes, and the water sprayed from the spray holes produces reverse power to drive the movable spray arm 4 to rotate to achieve a comprehensive washing effect on the bottom of the dish rack; the static spray arm 5 includes at least one set of spray ...

Embodiment 2

[0065] Such as Figure 1 to Figure 2 As shown, this embodiment is a further limitation of the first embodiment above. The spray system of the sink dishwasher in this embodiment includes a first electromagnetic valve 26, and the first electromagnetic valve 26 controls the flow of water through the first electromagnetic valve. After the valve 26, the respirator 28, and the water softener 29, it flows into the water storage unit 30; the water storage unit 30 is provided with a first water inlet pipe 21 and a third water inlet pipe 23, and the first water inlet pipe 21 is connected to the The static spray arm 5 on the side wall of the tank body 3, the third water inlet pipe 23 is connected to the dynamic spray arm 4 arranged at the bottom 2 of the tank body; it also includes a second solenoid valve 27, and the second solenoid valve 27 controls the water flow After passing through the second solenoid valve 27 , it enters the static spray arm 5 through the second water inlet pipe 22...

Embodiment 3

[0067] Such as Figure 3 to Figure 5As shown, this embodiment is a further limitation of any one of the first or second embodiments above. The side wall 3 of the tank body in this embodiment is provided with an installation groove 31 that matches the shape of the static spray arm 5 The installation groove 31 of the side wall of the tank body 3 is provided with an opening 32 passing through the first water inlet pipe 21 , the second water inlet pipe 22 , the steam pipe 24 and the drain pipe 25 .

[0068] At the same time, it includes a washer 33 matching the shape of the opening 32 of the installation groove 31. The washer 33 is installed on the side of the static spray arm 5 close to the side wall 3 of the tank body. The washer 33 is supported by a vibration-absorbing material. When the static spray arm 5. When working, the static spray arm 5 will vibrate due to the effect of spraying and high-pressure spraying. Working for a long time will cause damage to the static spray arm...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com