Slag discharging hole structure of vertical-mill grinding disc

A technology of slag discharge holes and grinding discs, which is applied in the direction of grain processing, etc., can solve the problems of reducing the number of grinding times, increasing the release and discharge probability of metal iron, and the difficulty of separating metal iron, so as to achieve the effect of prolonging the service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

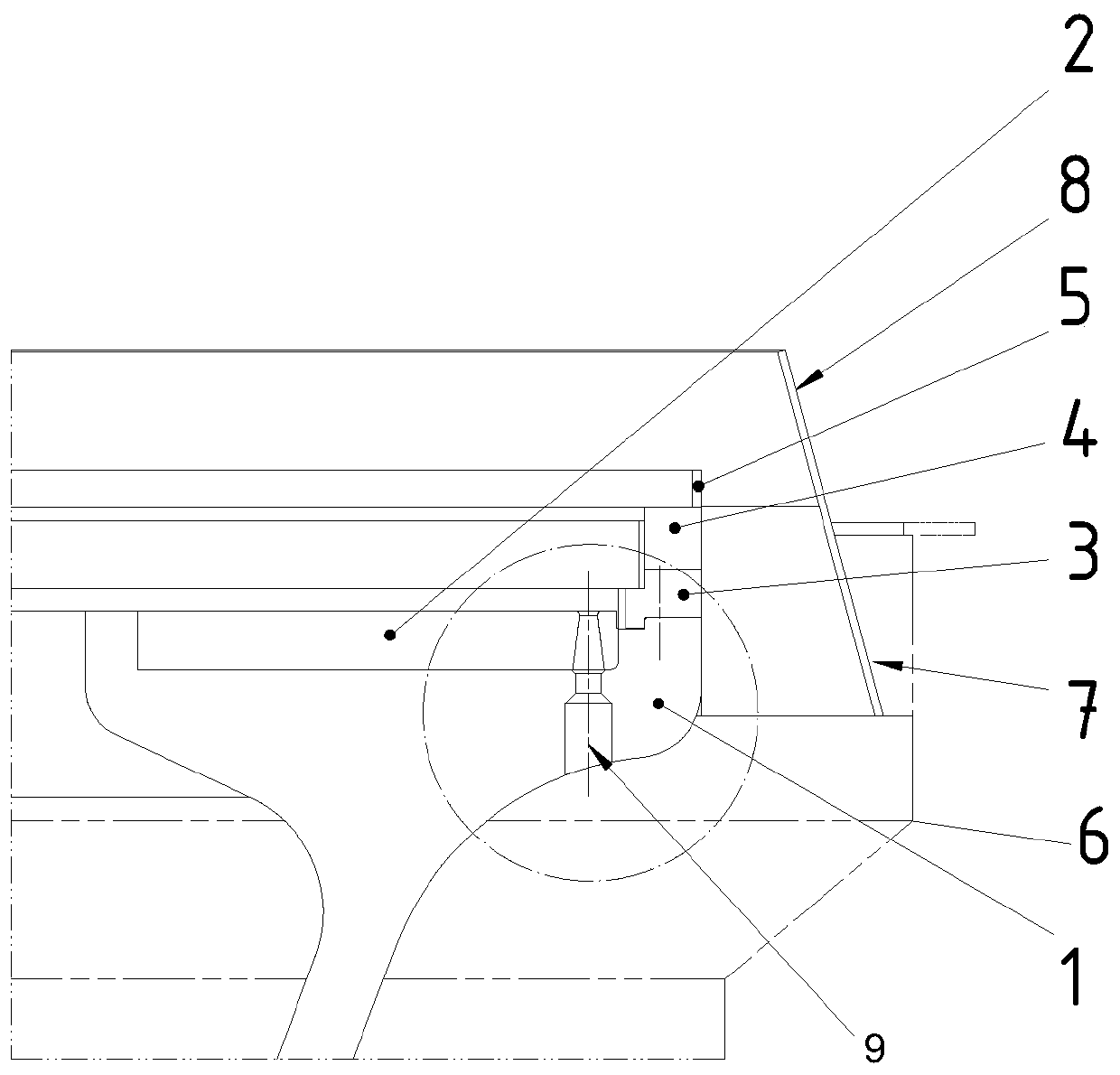

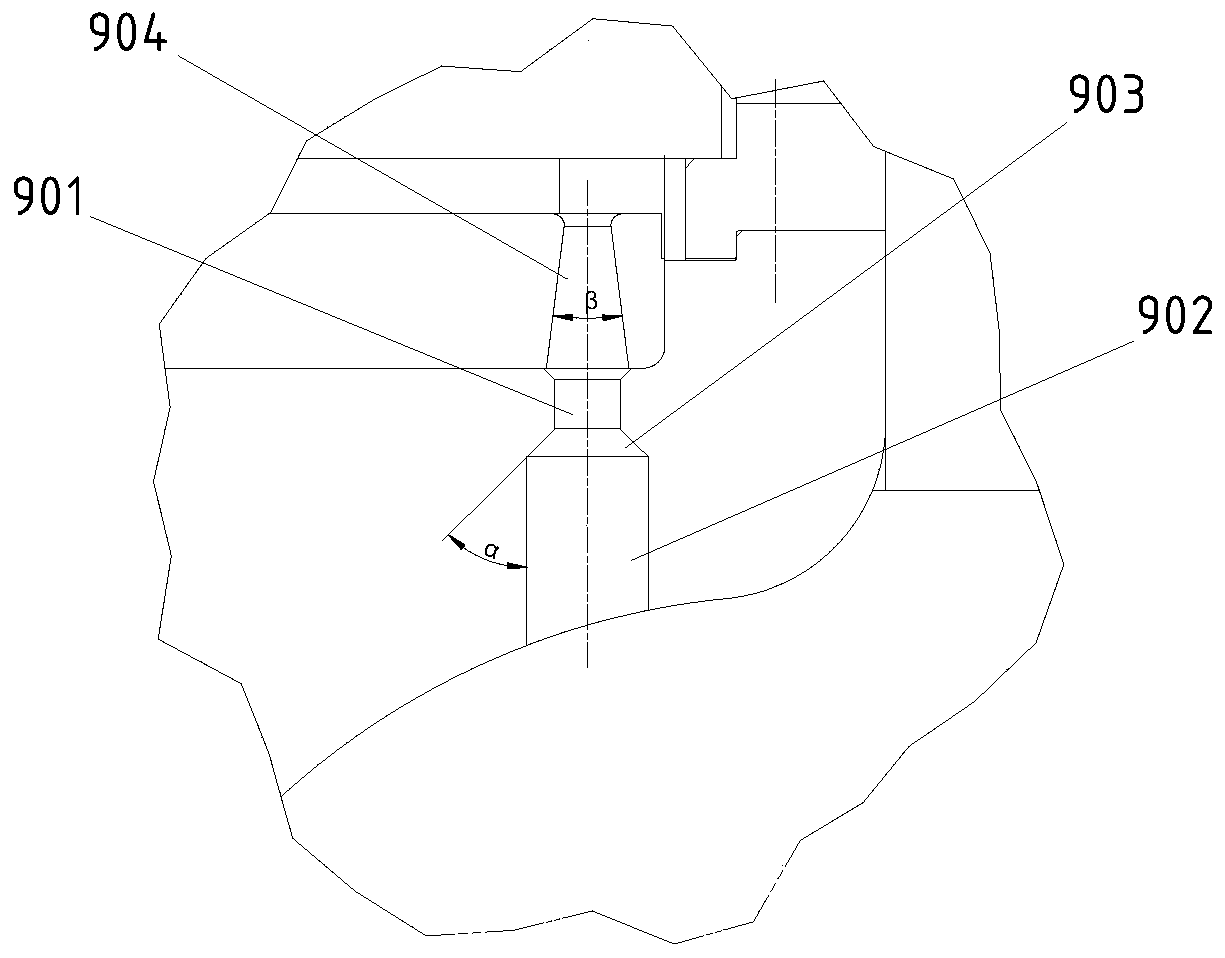

[0017] as attached figure 1 and 2 As shown, a vertical mill grinding disc slag discharge hole structure, which includes a grinding disc 1, a grinding disc liner 2 is installed on the grinding disc 1, a stopper base 3 is installed at the edge of the grinder 1, and the stopper base 3 The upper surface is fixed with a retaining ring 4, and the upper surface of the retaining ring 4 is fixed with a bulk material ring 5. An air ring 7 is arranged between the mill shell 6 and the grinding disc 1, and the upper end of the air ring 7 is connected with a The wear-resistant ring 8 is characterized in that: the edge of the grinding disc 1 and the grinding disc liner 2 is provided with a through slagging hole 9, and the slagging hole 9 is connected with the material retaining base 3, the material retaining ring 4 and the bulk material Neither ring 5 will intersect. The size of the slag discharge hole 9 must be determined according to the flow area, direction and flow velocity of the wind...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Taper | aaaaa | aaaaa |

| Taper | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com