Vacuum clamping assembly for robot

A technology of robots and vacuum clamps, which is applied in the field of robots, can solve the problems of inconvenient picking and placing of objects, and achieve the effects of simple structure, convenient use, and reliable suction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] In order to further illustrate the technical means and effects adopted by the present invention to achieve the predetermined purpose, the specific implementation, structural features and effects of the present invention will be described in detail below with reference to the drawings and examples.

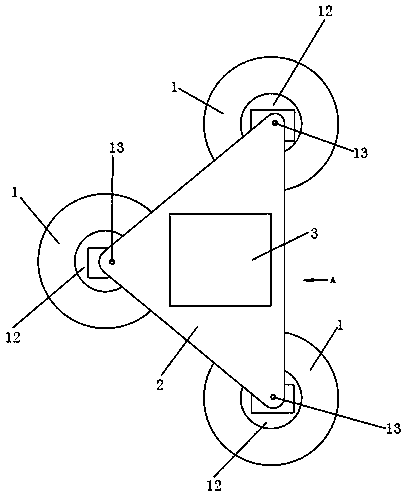

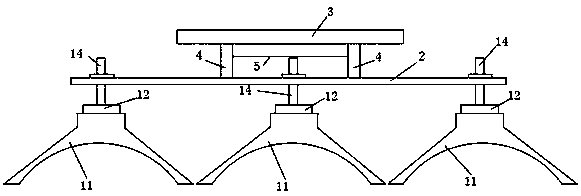

[0026] In order to solve the problem of inconvenience in picking and placing articles by the existing robot, this embodiment provides a vacuum clamping assembly for a robot. Such as figure 1 with figure 2 As shown, the vacuum clamping assembly of this embodiment includes a plurality of suction bodies 1 that can suck and transfer the same object 100 to be clamped, a connecting plate 2 that connects the plurality of suction bodies 1 into one body, and the upper part of the connecting plate 2 is installed by a bracket An installation platform 3, which is connected with the robot arm.

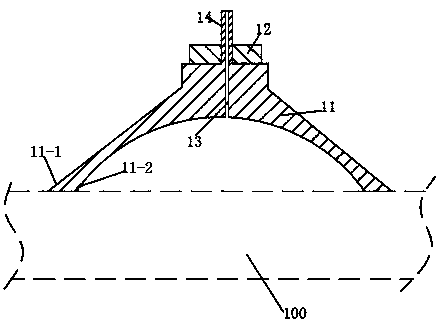

[0027] Such as image 3 As shown, the adsorption body 1 of this embodiment includes an annular su...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com