Rubber bushing vulcanization mold

A technology of vulcanization molds and rubber bushings, applied in the field of vulcanization molds, can solve problems such as reducing production efficiency, difficult to seal rubber, and molds cannot be held down, so as to improve quality and pass rate, solve surface quality problems, and facilitate opening. The effect of mold pickup

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

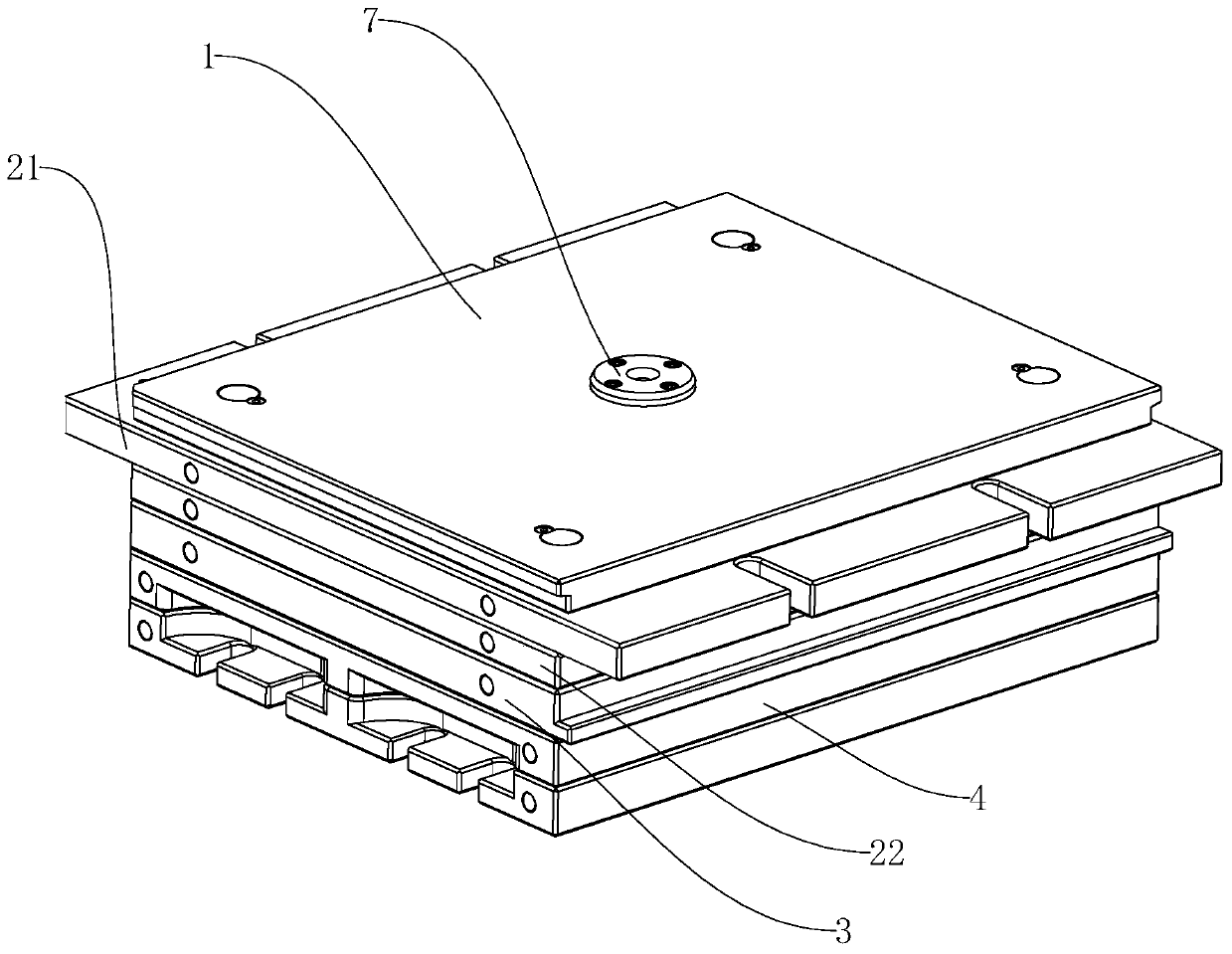

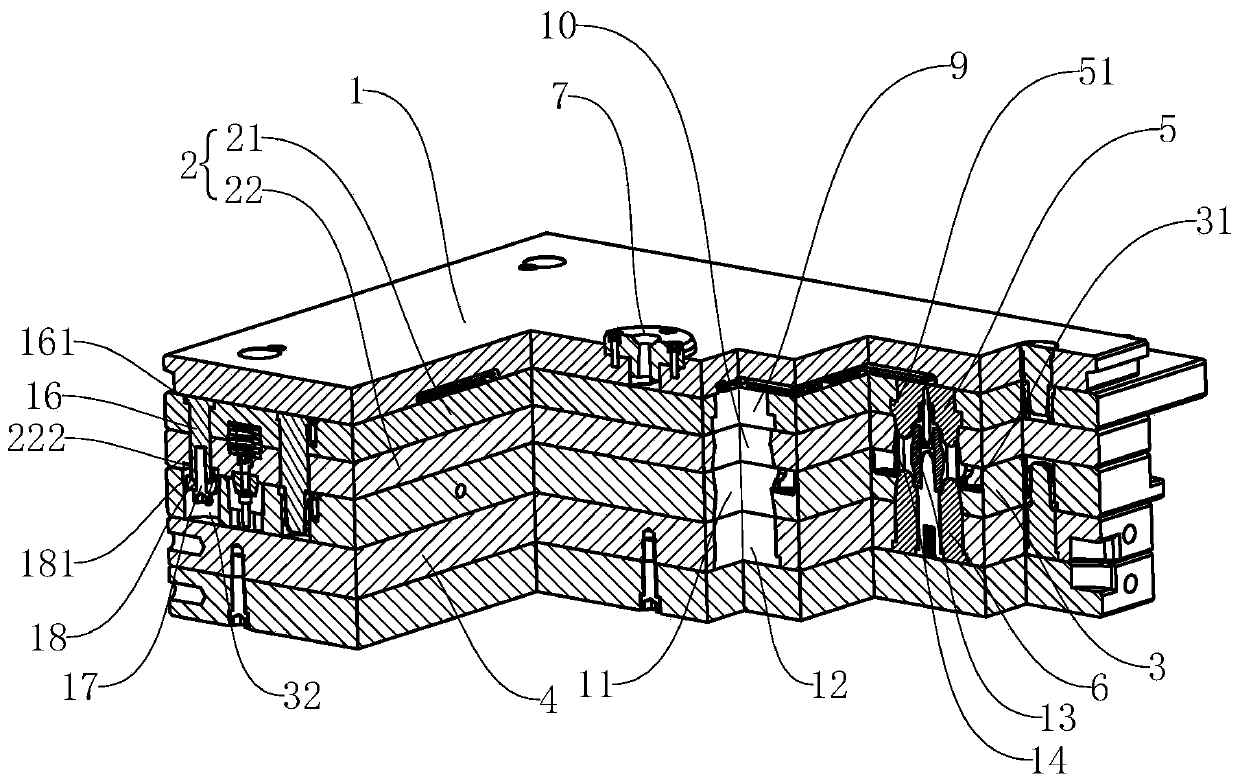

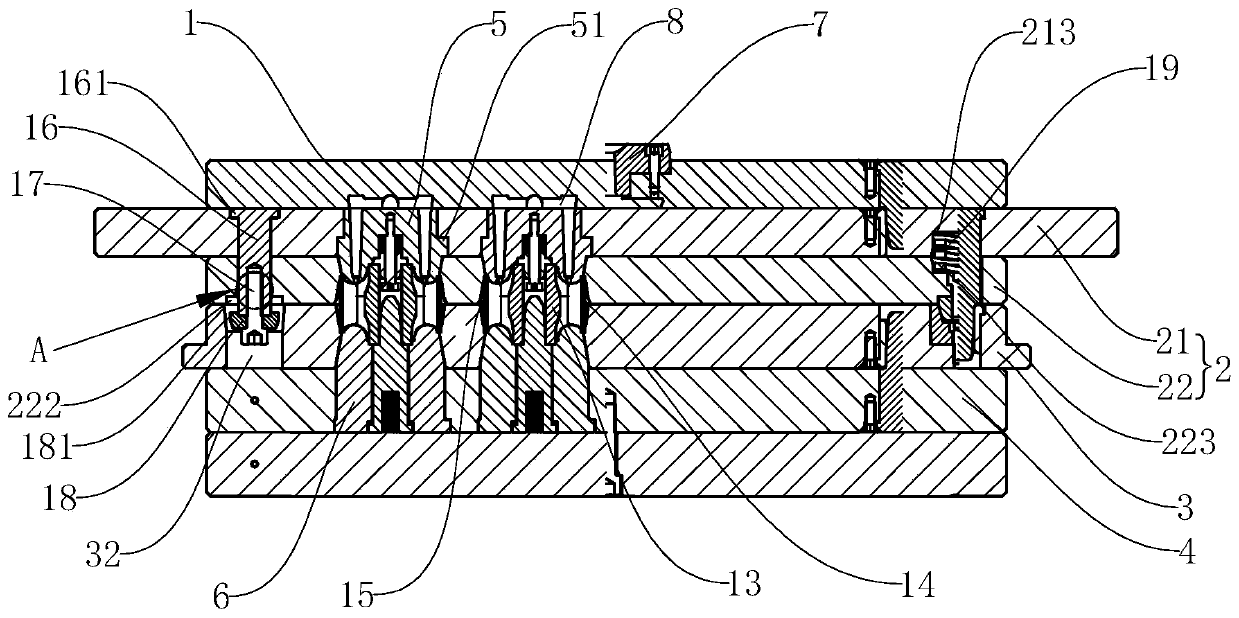

[0033]Embodiment 1: As shown in the figure, a rubber bush vulcanization mold includes a flow channel plate 1, an upper mold plate 2, a middle mold plate 3, a lower mold plate 4, an upper mold insert 5 and a lower mold arranged in sequence from top to bottom The insert 6, the runner plate 1 is provided with a sprue sleeve 7 and a plurality of runners 8, the glue inlet of the runner 8 is connected with the sprue sleeve 7, and the glue outlet of the runner 8 is inlaid with the corresponding upper die. The upper template 2 includes a first upper template 21 and a second upper template 22, and a plurality of clutch mechanisms are arranged between the first upper template 21 and the second upper template 22 for springing off and always connecting the first Upper template 21 and the second upper template 22, the first upper template 21 is provided with a plurality of first upper die cavities 9 for fixing the upper mold insert 5, and the second upper template 22 is provided with a plur...

Embodiment 2

[0034] Embodiment 2: As shown in the figure, a rubber bush vulcanization mold includes a flow channel plate 1, an upper mold plate 2, a middle mold plate 3, a lower mold plate 4, an upper mold insert 5 and a lower mold arranged in sequence from top to bottom The insert 6, the runner plate 1 is provided with a sprue sleeve 7 and a plurality of runners 8, the glue inlet of the runner 8 is connected with the sprue sleeve 7, and the glue outlet of the runner 8 is inlaid with the corresponding upper die. The upper template 2 includes a first upper template 21 and a second upper template 22, and a plurality of clutch mechanisms are arranged between the first upper template 21 and the second upper template 22 for springing off and always connecting the first Upper template 21 and the second upper template 22, the first upper template 21 is provided with a plurality of first upper die cavities 9 for fixing the upper mold insert 5, and the second upper template 22 is provided with a plu...

Embodiment 3

[0035] Embodiment 3: As shown in the figure, a rubber bush vulcanization mold includes a flow channel plate 1, an upper mold plate 2, a middle mold plate 3, a lower mold plate 4, an upper mold insert 5 and a lower mold arranged in sequence from top to bottom The insert 6, the runner plate 1 is provided with a sprue sleeve 7 and a plurality of runners 8, the glue inlet of the runner 8 is connected with the sprue sleeve 7, and the glue outlet of the runner 8 is inlaid with the corresponding upper die. The upper template 2 includes a first upper template 21 and a second upper template 22, and a plurality of clutch mechanisms are arranged between the first upper template 21 and the second upper template 22 for springing off and always connecting the first Upper template 21 and the second upper template 22, the first upper template 21 is provided with a plurality of first upper die cavities 9 for fixing the upper mold insert 5, and the second upper template 22 is provided with a plu...

PUM

| Property | Measurement | Unit |

|---|---|---|

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com