Railway vehicle collision pillar and vehicle head structure with same

A technology for rail vehicles and rib plates, which is applied to railway car body parts, railway vehicle wheel guards/buffers, buffer cars, etc. problems, to reduce damage, enhance structural strength, and maintain compactness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

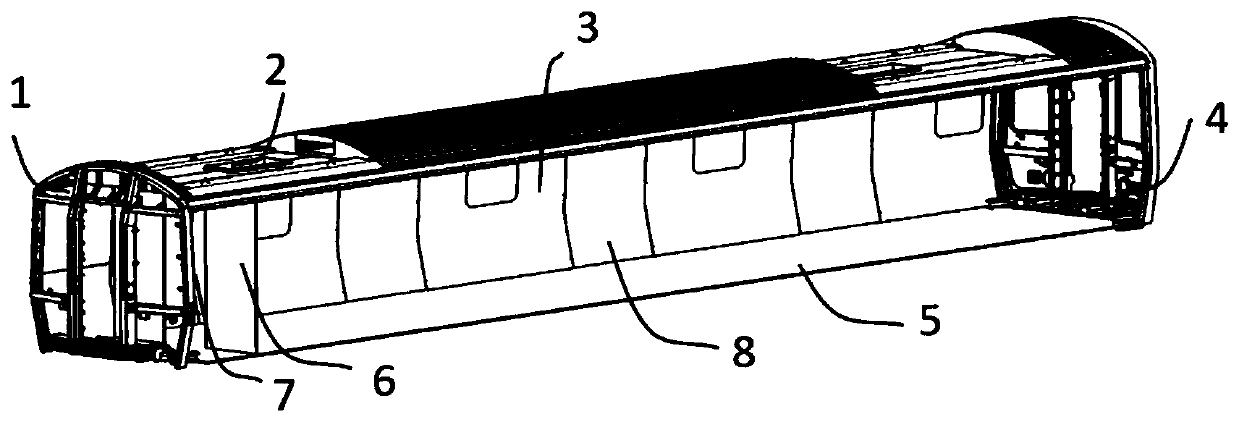

[0017] refer to figure 1 , The rail vehicle body usually includes a front end 1 , a roof 2 , a side wall 3 , a rear end 4 , and an underframe 5 . The five-part structure forms a complete enclosed space for carrying passengers and other equipment of the vehicle. There is often a driver's cab partition 6 inside this space. The space inside the vehicle is divided into two parts by the partition wall 6 of the driver's compartment: the driver's compartment 7 and the passenger compartment 8 . Most of the U.S. subway rail vehicles are required to be able to ensure the safety of the driver when a 6-car formation collides at 24 kilometers per hour, and to ensure the safety of the passenger compartment when a 6-car formation collides at a speed of 40 kilometers per hour. That is, when the impact speed is less than 24 kilometers per hour, the driver's cab 7 needs to have enough living space. When the impact speed is less than 40 kilometers per hour, the cabin 8 needs to have enough li...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com