Adjacent space propeller with tip actively blowing air

A near-space, propeller technology, applied in propellers, transportation and packaging, aircraft parts, etc., can solve the problems of the complete consistency of centrifugal force, the influence of propeller structural strength, and the complexity of the synergistic jet mechanism. , centrifugal force and the effect of small deviation of centrifugal force

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

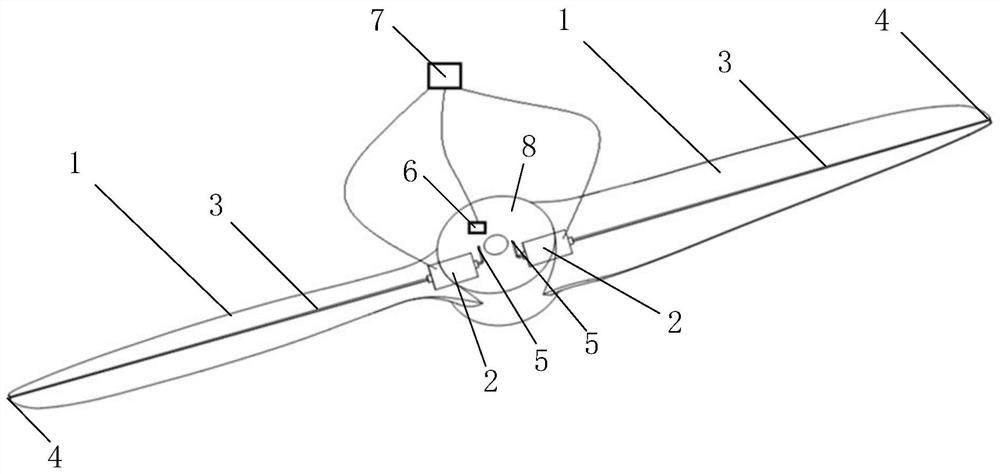

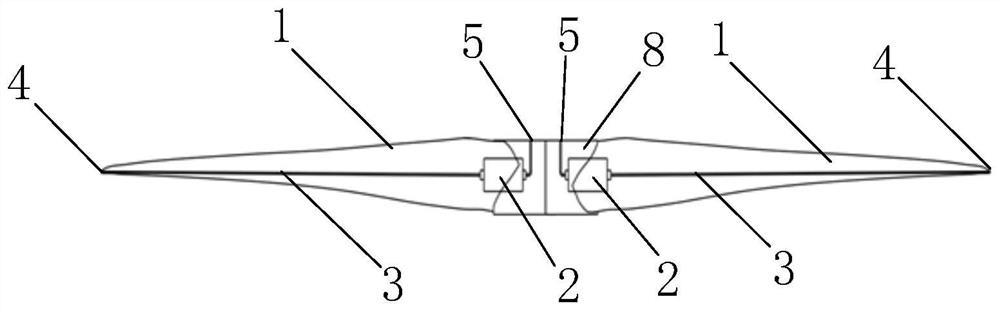

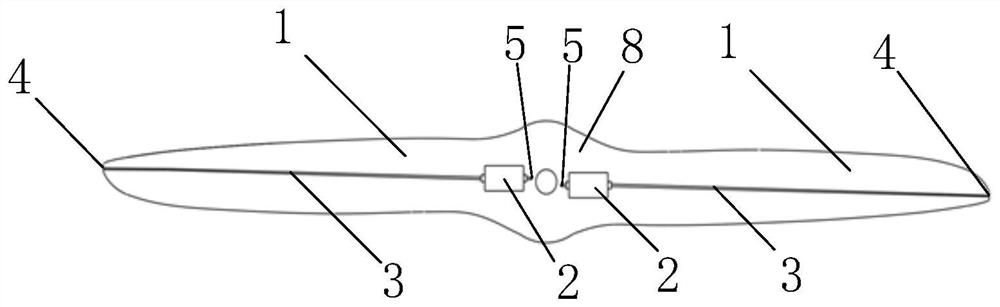

[0024] Attached below Figure 1-6 , the present invention will be further described from the air blowing system layout, air blowing control and practical application effect.

[0025] The present invention provides a kind of adjacent space propeller that propeller tip actively blows air, such as figure 1 , figure 2 and image 3 As shown, the propeller includes a blade 1 and a hub 8. Taking a propeller with two blades 1 as an example, the present invention is provided with an air pump 2, an airflow conduit 3, an air blowing port 4, and an air suction port 5 on the propeller. , the acceleration sensor 6 and the control circuit 7, the control circuit 7 controls the work of the air pump 2, and the gas in the suction port 5 is passed through the airflow conduit 3, and is ejected at the blowing port 4 to form the active blowing of the tip of the paddle. Both the acceleration sensor 6 and the control circuit 7 are located inside the hub 8 . There are two suction ports 5, two air ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com