Rewinding mechanism for processing surface markings of optical fiber cable

A fiber optic cable and marking technology, which is applied in the field of optical cable manufacturing, can solve the problems of low manual erasing efficiency, irregular wiring, and production delays, and achieve the effects of avoiding personnel contact with reagents, protecting health, and reducing hazards

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

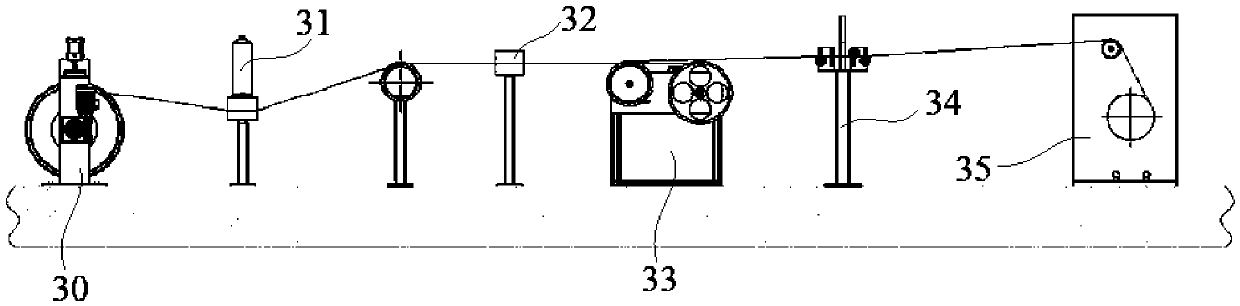

[0030] Embodiment 1: A rewinding mechanism for optical fiber cable surface marking processing, including an automatic pay-off machine 30, an automatic word erasing machine 31, a diameter measuring instrument 32, a tractor 33, a printing machine 34 and an automatic wire take-up mechanism 35, the Automatic pay-off machine 30, automatic letter erasing machine 31, caliper 32, tractor 33, printing machine 34 and automatic take-up mechanism 35 are arranged and fixed on the workbench in sequence, and material strips 37 are released from automatic pay-off machine 30 and sequentially Through the automatic character erasing machine 31, the diameter measuring instrument 32, the tractor 33 and the printing machine 34, and then through the automatic winding mechanism 35, it is wound on the receiving tray;

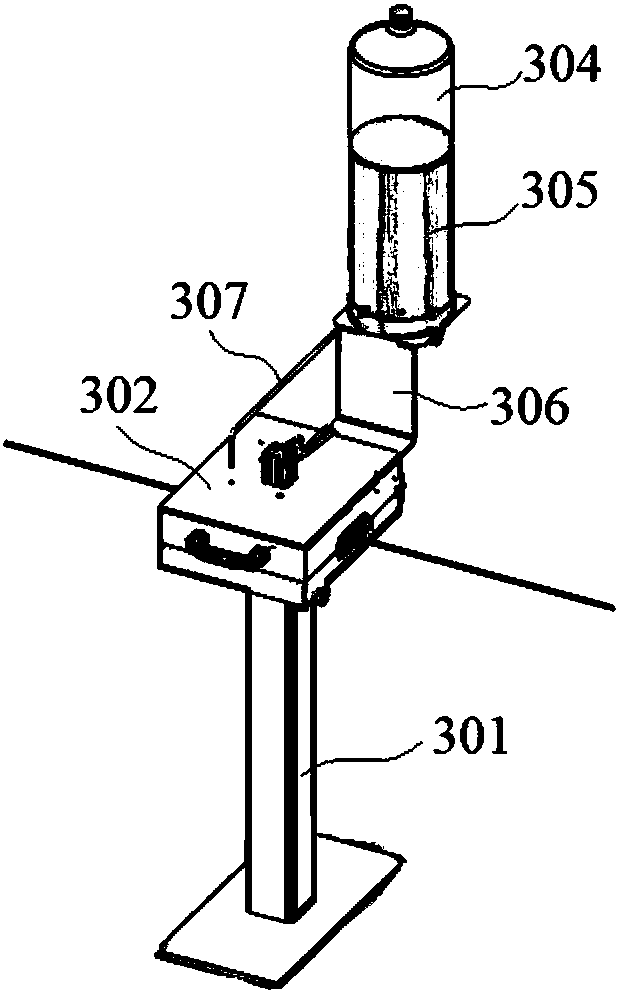

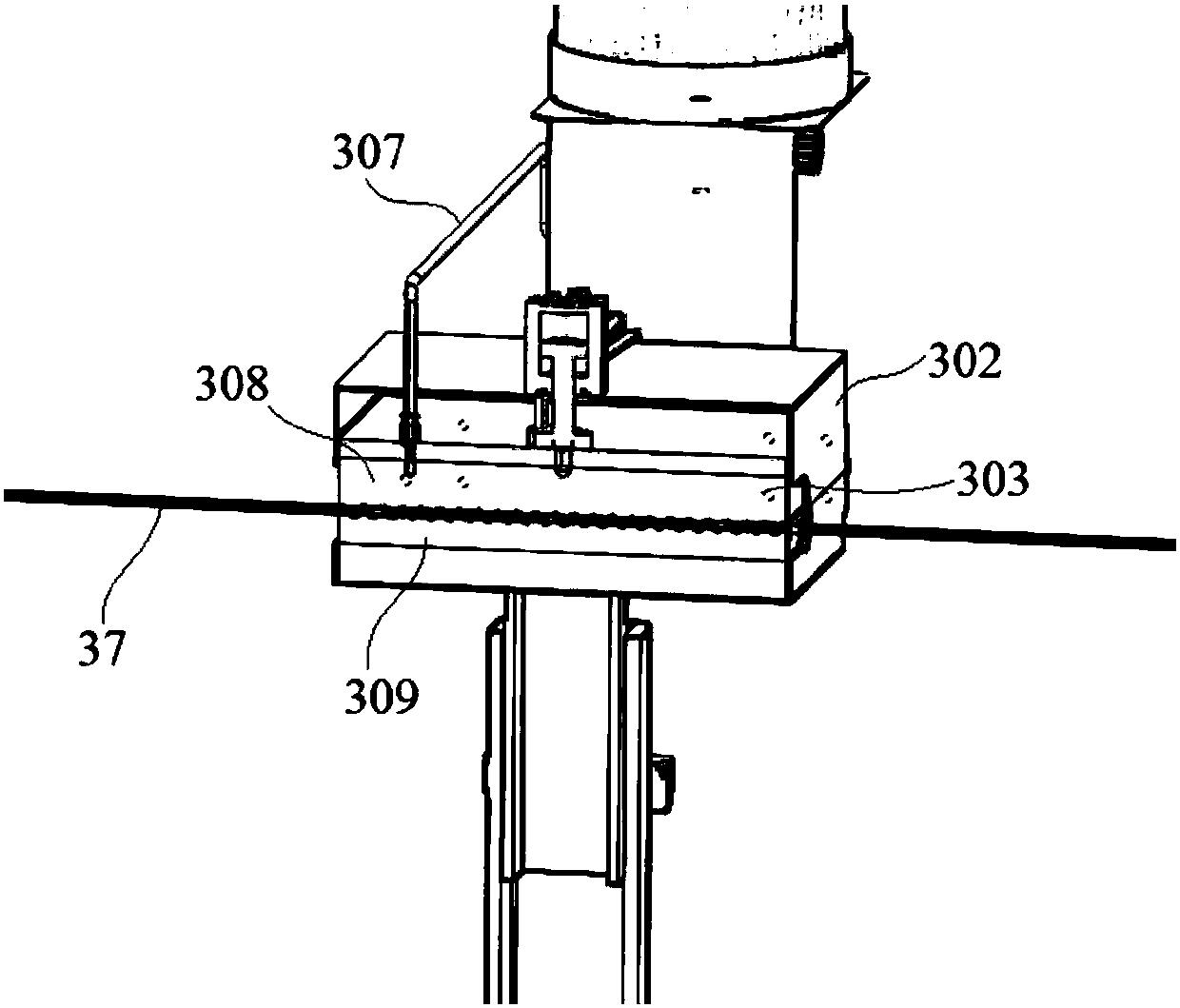

[0031] The automatic character erasing machine 31 further includes a base 301, a character erasing box 302, a character erasing cotton 303 arranged in the character erasing box 302, and ...

Embodiment 2

[0036] Embodiment 2: A rewinding mechanism for optical fiber cable surface marking processing, including an automatic pay-off machine 30, an automatic character erasing machine 31, a diameter measuring instrument 32, a tractor 33, a printing machine 34 and an automatic wire take-up mechanism 35, the Automatic pay-off machine 30, automatic letter erasing machine 31, caliper 32, tractor 33, printing machine 34 and automatic take-up mechanism 35 are arranged and fixed on the workbench in sequence, and material strips 37 are released from automatic pay-off machine 30 and sequentially Through the automatic character erasing machine 31, the caliper 32, the tractor 33 and the printing machine 34, and then through the automatic winding mechanism 35, it is wound on the receiving tray;

[0037] The automatic character erasing machine 31 further includes a base 301, a character erasing box 302, a character erasing cotton 303 arranged in the character erasing box 302, and a reagent pot 304...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com