Cutting method of hard optical fiber

A cutting method and fiber optic fiber technology, applied in glass manufacturing equipment, manufacturing tools, etc., can solve the problems of affecting product quality, unquantifiable melting depth and width, and low cutting efficiency, so as to reduce labor intensity and improve cutting efficiency. The effect of improving silk efficiency and improving flatness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Example Embodiment

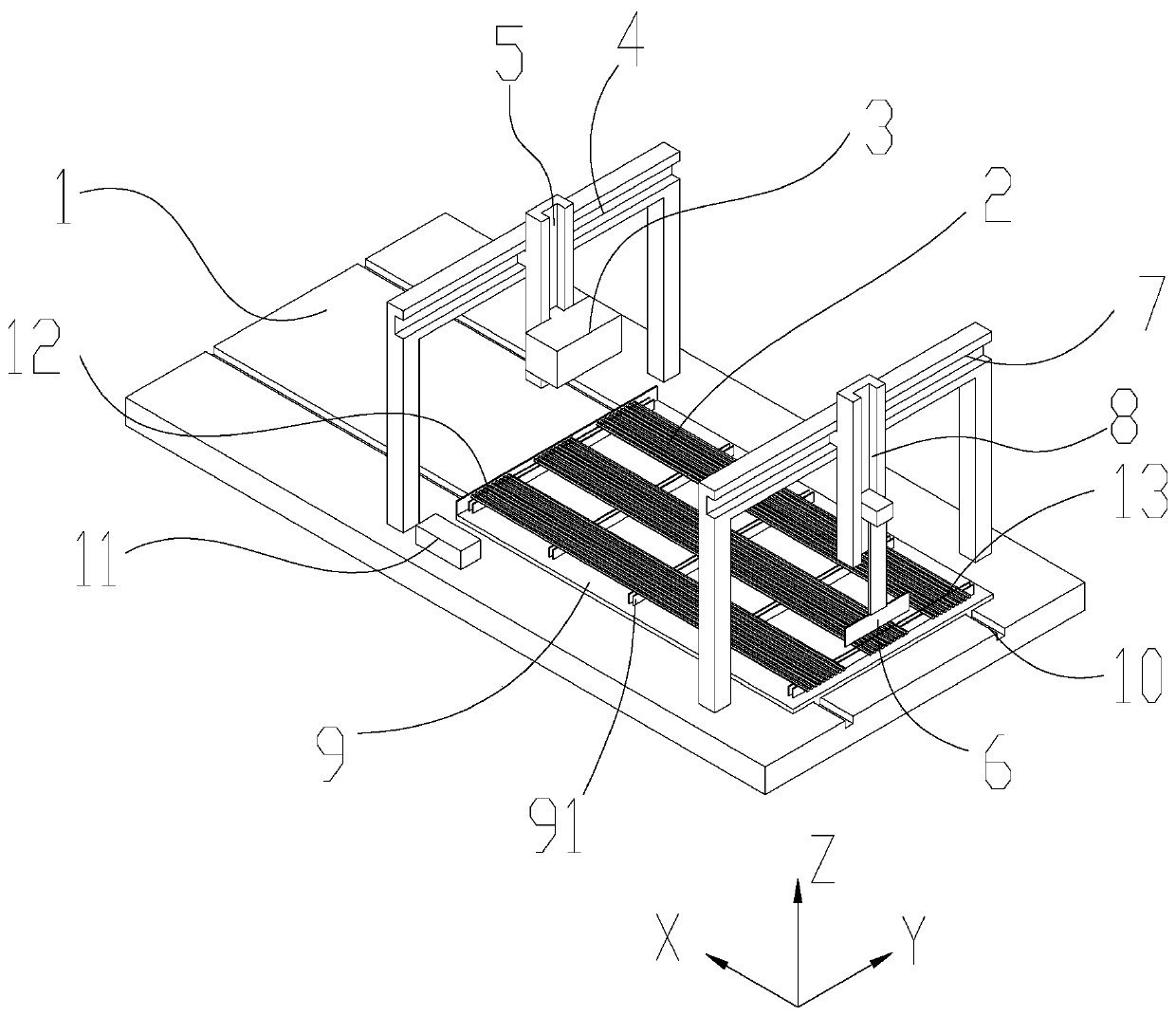

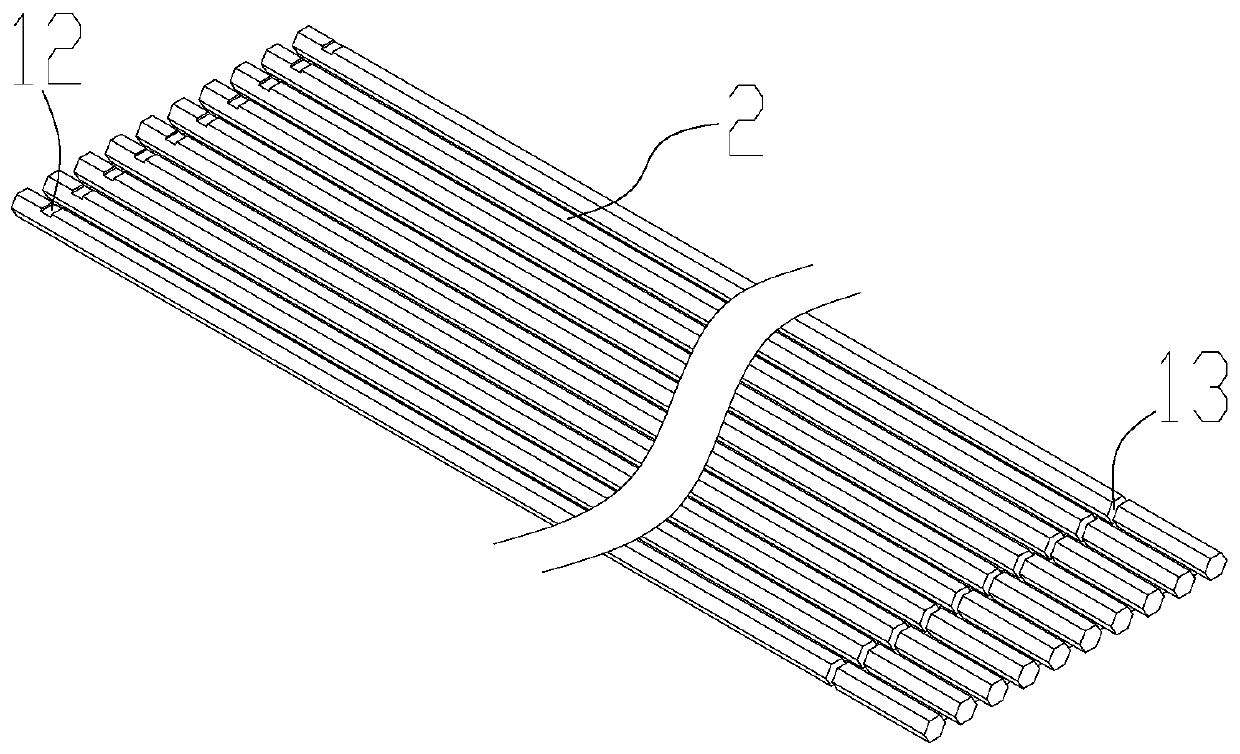

[0023] Reference figure 1 with figure 2 The present invention is a method for cutting hard optical fiber filaments. First, a laser is used to preliminarily cut the optical fiber filament 2 to form a cutting trace 12, and then a cutting knife 6 is used to cut the optical fiber filament 2 along the cutting trace 12 to form a fracture 13. In this way, cutting in two times, preliminary cutting by laser, and cutting by the cutting knife 6, can quantify the depth and width of the fiber wire 2 port; avoid the burrs on the section caused by manual skimming in the traditional method, and improve the section of the fiber wire 2 after cutting The flatness of the fiber is improved, and the accuracy of the cutting length is improved. The deviation of 0.5~1mm in the traditional method is reduced to less than 0.1mm, and the accuracy is increased by more than 5 times. The whole process adopts automatic feeding and automatic feeding to cut the fiber wire 2, thereby reducing labor Labor intensi...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap