A kind of low-conductivity cooling liquid and preparation method thereof

A technology of coolant and low conductivity, applied in lubricating compositions, petroleum industry, etc., can solve problems such as poor stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

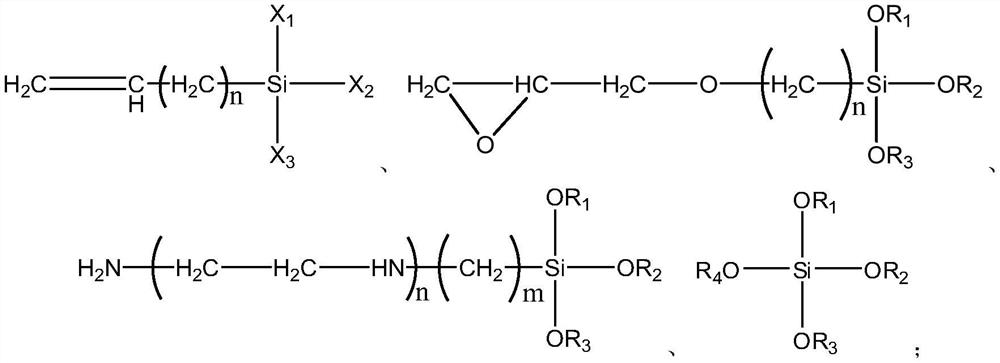

Method used

Image

Examples

Embodiment Construction

[0027] The organosilicon compounds used in the following examples and comparative examples are all products of Dow Corning Co., Ltd., 5-methoxyuracil is a product of Ruierfeng Chemical Co., Ltd., and 4-amino-5-imidazole carboxamide is a product of Shanghai Jiangzhou Chemical Co., Ltd. The company's products, methyl benzotriazole is a product of Nantong Kanghua Chemical Co., Ltd., and N-lauroyl sarcosine is a product of Beijing Bailingwei Technology Co., Ltd.

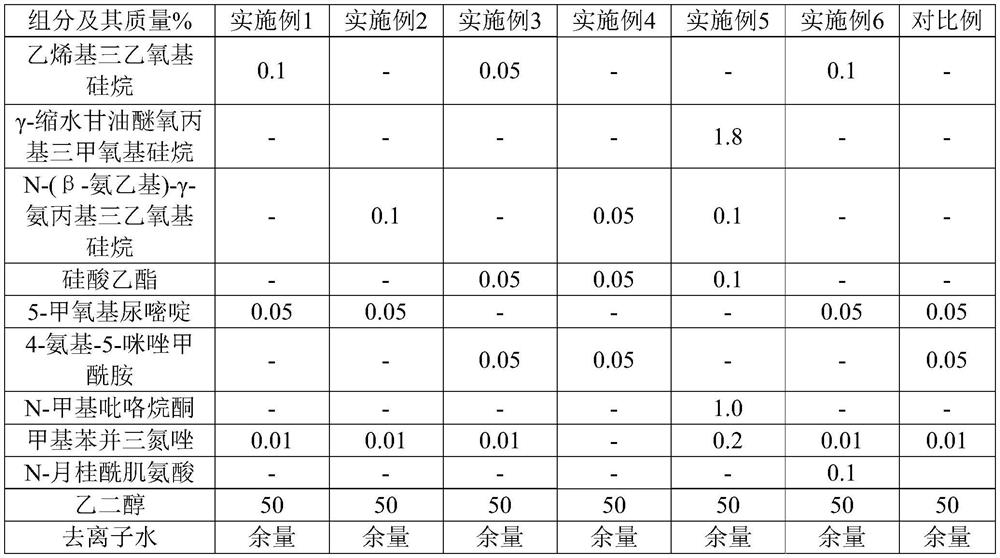

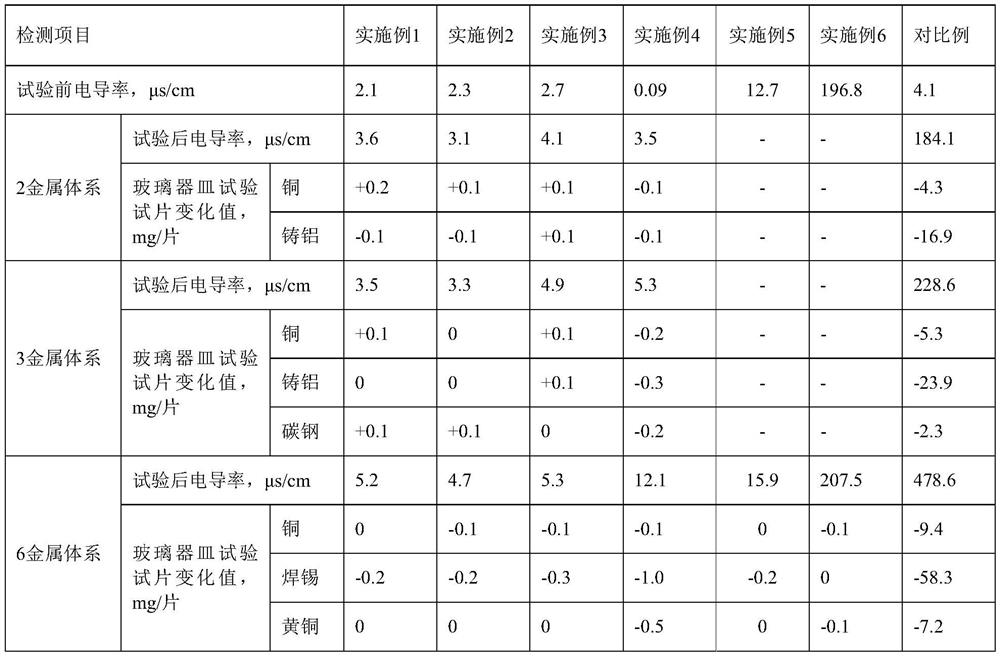

[0028] Each component and its mass percentage in Examples 1-6 and Comparative Examples are shown in Table 1.

[0029] Table 1

[0030]

[0031] The preparation method of the cooling liquid described in Examples 1-6 is: mix the organosilicon compound, the nitrogen-containing compound and the azole compound evenly, then add it to the glycol, stir at room temperature for more than 20 minutes, and finally add deionized water and stir evenly , to obtain a low-conductivity coolant.

[0032] The preparation method of the c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com