Fireproof cable

A technology of fireproof cables and conductors, which is applied in the direction of insulated cables, cables, circuits, etc., can solve the problems that affect the use and promotion of fireproof cables, the difficulty of long-distance transportation, and the severely restricted use environment, etc., and achieve simple and stable structure, fireproof Stable performance and strong adaptability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] The present invention will be described in further detail below in conjunction with the accompanying drawings.

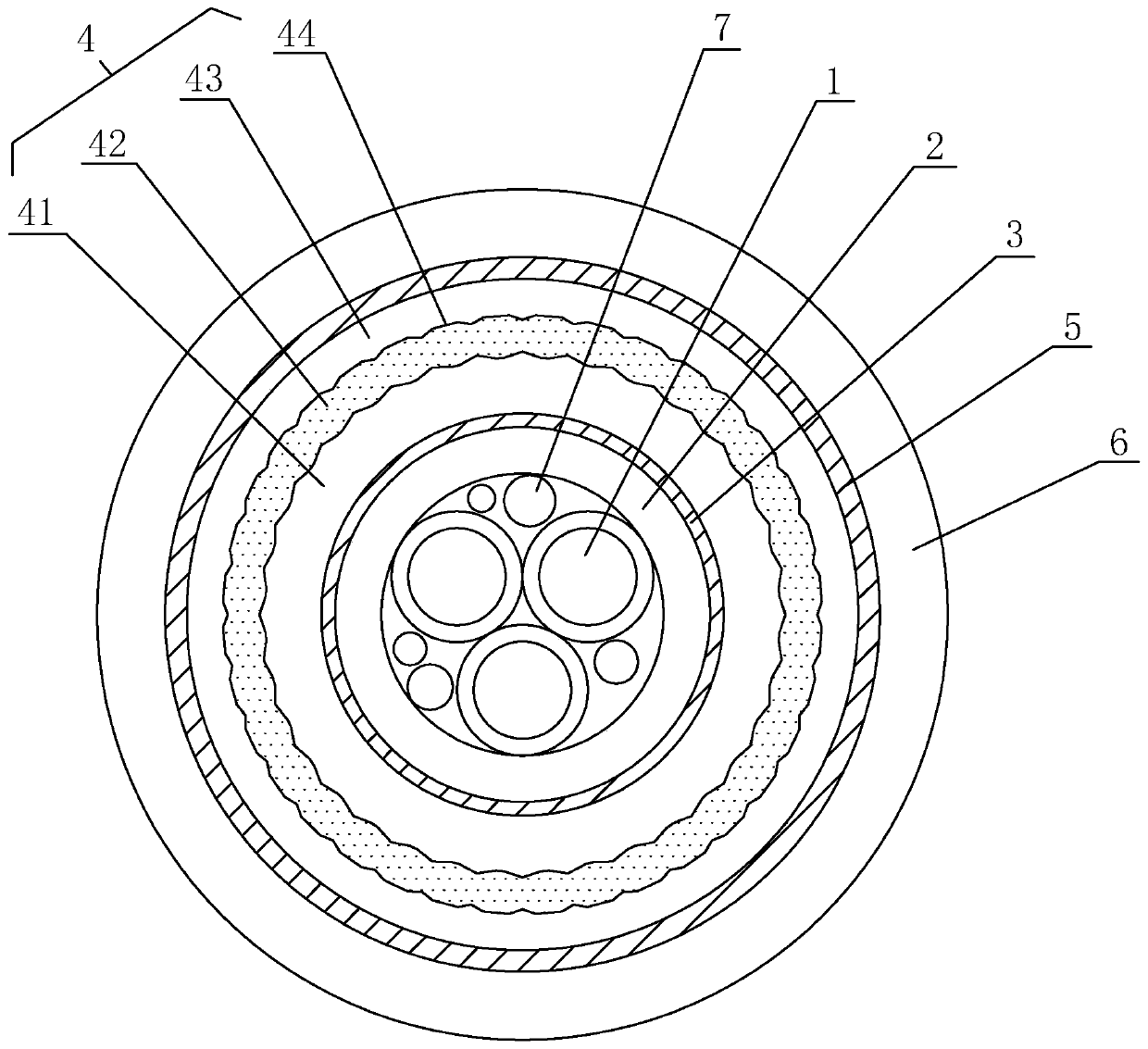

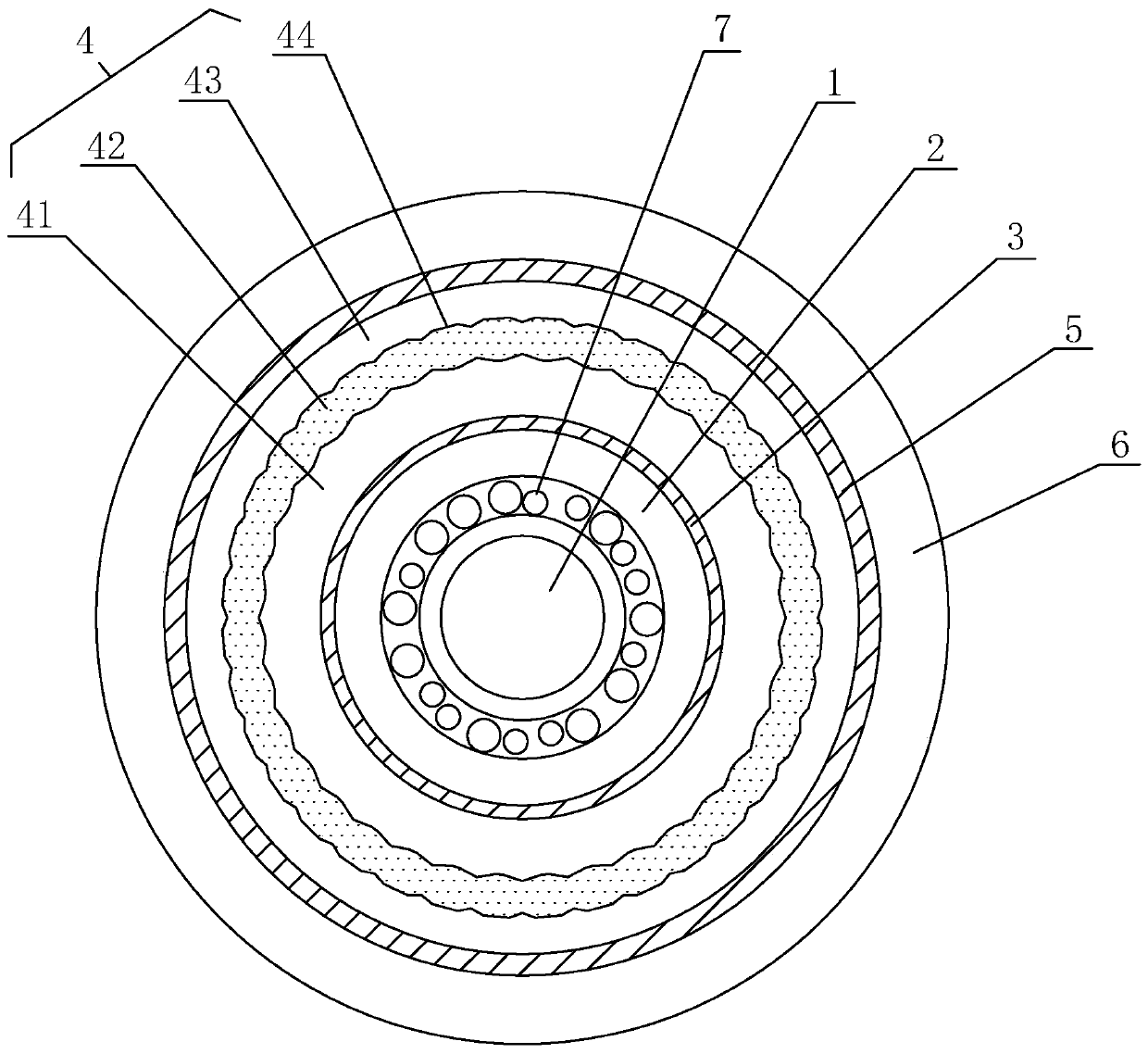

[0032] refer to figure 1 , is a fireproof cable disclosed by the present invention, including a conductor 1, and a wrapping tape 2, a metal shielding layer 3, a fireproof insulating layer 4, an armor layer 5 and an outer sheath 6 are arranged outside the conductor 1 in sequence.

[0033] The conductor 1 is a single core or more than two multi-cores and is wrapped with an insulating layer. The conductor 1 is made of aluminum alloy and its eccentricity is less than or equal to 10%. Multi-core cable reference figure 1 , single core cable refer to figure 2 . According to the use environment or requirements, a single-core or multi-core structure can be adopted, and the rounder conductor 1 has a higher conduction rate and better conduction effect.

[0034] The wrapping tape 2 is wound outside the conductor 1, and the wrapping tape 2 is made of refractory mica ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com