Superconducting magnetic separator parallel separation mechanism capable of achieving uniform water distribution

A uniform water distribution and superconducting magnetic technology, applied in the direction of high-gradient magnetic separators, can solve the problem of uneven water distribution, achieve the effects of improving mineral processing accuracy, avoiding clogging, improving processing accuracy and industrial production stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

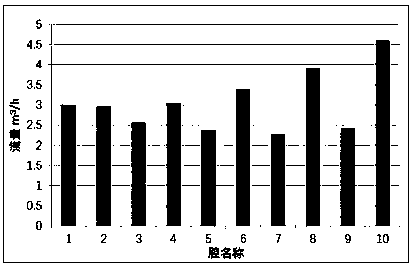

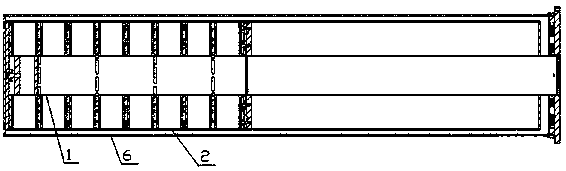

[0032] 500mm caliber, effective magnetic field length 1200mm Superconducting magnetic separator, divided into 10 sorting chambers, each sorting chamber has an effective steel wool area length of 100mm; the inner diameter of the water inlet pipe is 150mm, and the cross-sectional area is 17662.5mm 2 , the annular gap between the secondary outer sleeve and the outer sleeve is 30mm, and the converted cross-sectional area is about 20000 mm 2 . If the flow field is not optimized, the pressure distribution of the ore feed flow field of the 10 cavities is as follows figure 1 As shown, the ore flow estimation of 10 cavities is as follows figure 2 shown. Using the technical solution provided by this patent, the cross-sectional area of the return pipe of the outer sleeve is greatly reduced to less than 8500mm 2 , that is, the cross-sectional area of the inlet pipe 1 where the cross-sectional area of the return pipe of the outer sleeve is less than 50%, the flow rate of the 10 c...

Embodiment 2

[0034] 500mm caliber, effective magnetic field length 1200mm Superconducting magnetic separator, divided into 10 sorting chambers, each sorting chamber has an effective steel wool area length of 100mm; the inner diameter of the water inlet pipe is 150mm, and the cross-sectional area is 17662.5mm 2 , the annular gap between the secondary outer sleeve and the outer sleeve is 30mm, and the converted cross-sectional area is about 20000 mm 2 . Using the technical solution provided by this patent, a baffle is added to the steel wool cross-section of the 10 cavities, and small holes with a diameter of 5mm are drilled on the baffle, and the total water cross-sectional area of all the small water holes is 1400mm 2 , the total cross-sectional area of 10 parallel cavity baffles is 14000 mm 2 , that is, the total area of the cross-sections of the water distribution channels of all n sorting chambers or the total area of the cross-sections of n high-gradient mediums is less than 8...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com