Reciprocating continuous feeding superconducting magnetic separator and its magnetic separation method

A reciprocating, superconducting magnetic technology, applied in the direction of high-gradient magnetic separators, etc., can solve the problem that the high magnetic field of the solenoid superconducting magnet cannot be used to continuously feed ore and sort continuously, so as to ensure continuous industrial production and avoid blockage , The effect of reducing valve wear

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

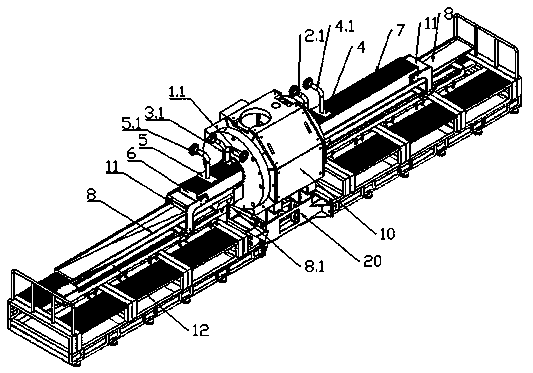

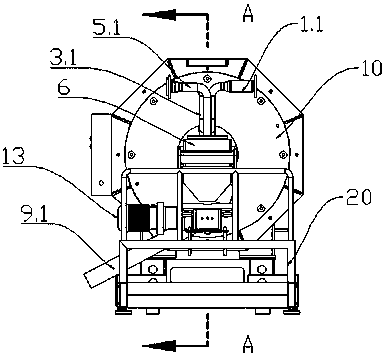

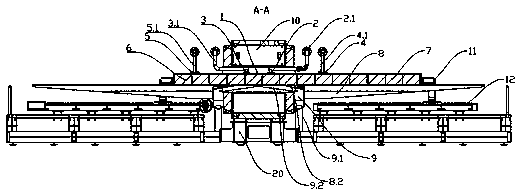

[0036] Such as figure 1 As shown in -4, a reciprocating continuous ore feeding superconducting magnetic separator includes a base 20, a reciprocating series tank medium box, an ore feeding port 1, a right in-field flushing port 2, a left in-field flushing port 3, a right Side off-site flushing discharge port 4, left off-site flushing discharge port 5, magnetic ore collection tank 8, non-magnetic ore collection tank 9, magnetic ore collection channel 8.2, non-magnetic ore collection channel 9.2 and superconducting magnets 10. The superconducting magnet 10 is a solenoid superconducting magnet and is placed horizontally and fixed on the base 20. The reciprocating series tank medium box can move back and forth in the superconducting magnet 10 and is divided into the left sorting chamber 6 and the sorting chamber 7 on the right side; the ore feeding port 1, the flushing port 2 in the right field and the flushing port 3 in the left field are all located in the magnetic field of the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com