A continuous production method for electrochemically synthesizing sebacate compounds

A technology of sebacate and production method, which is applied in the field of continuous production of electrochemical synthesis of sebacate compounds, can solve problems such as excessive anode failure, and achieve the advantages of prolonging service period, reducing operating cost and reducing corrosion risk. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

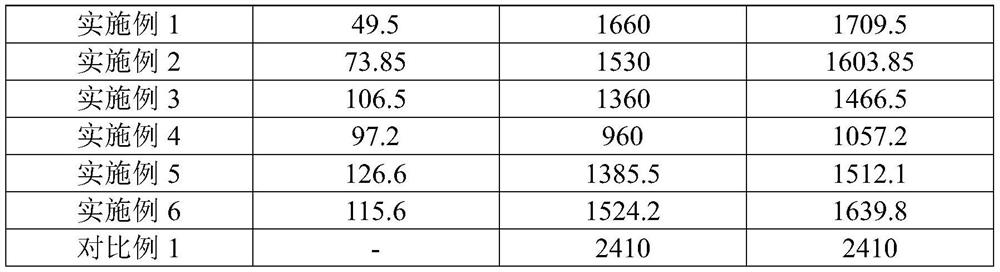

Embodiment 1

[0046] [Example 1] Synthesis of dimethyl sebacate

[0047] No. 1 electrolytic cell is equipped with mesh Ti-based IrO 2 Anode and stainless steel cathode, anode area is 0.01m 2 ; The cathode and anode are alternately arranged horizontally. Set the electrolysis potential to 1.2V and the electrolysis current density to 500A / m 2 .

[0048] No. 2 electrolytic cell is equipped with mesh platinum-titanium anode and graphite cathode, and the anode area is 0.1m 2 ; The cathode and anode are arranged alternately vertically, and the extension direction of the net surface of the cathode and anode is consistent with the flow direction of the material. Set the electrolysis potential to 3V and the electrolysis current density to 2000A / m 2 .

[0049] Dissolve 1600g monomethyl adipate and 105g potassium methoxide in 1600g and 1600g methanol respectively to form feed solution A and feed solution B; simultaneously feed feed solution A and feed solution B into the raw material mixer for mi...

Embodiment 2

[0055] [Example 2] Synthesis of diethyl sebacate

[0056] No. 1 electrolyzer selects meshed Ti-based PbO 2 For the anode and the stainless steel cathode, the No. 2 electrolytic cell selects the plate-shaped platinum anode and the platinum-titanium cathode, which are arranged in the arrangement in Example 1. Adjust the electrolytic potential of No. 1 electrolytic cell to 1.6V and the electrolytic current density to 700A / m 2 , the electrolytic potential of No. 2 electrolytic cell is 2.8V, and the electrolytic current density is 1800A / m 2 .

[0057] Dissolve 1740g monoethyl adipate and 80g sodium hydroxide in 1740g and 1710g of solvent benzene respectively to form feed liquid A and feed liquid B; feed liquid A and feed liquid B into the raw material mixer simultaneously for 10 minutes, control Feeding speed, so that material liquid A, B complete feeding at the same time.

[0058] The mixed material is 2m 3 The feed rate of / h is pumped into the No. 1 electrolytic cell, and t...

Embodiment 3

[0063] [Example 3] Synthesis of dipropyl sebacate

[0064] No. 1 electrolyzer selects meshed Ti-based RuO 2 For the anode and stainless steel cathode, plate-shaped platinum anode and platinum-titanium cathode are selected for the No. 2 electrolytic cell, and are arranged in the arrangement in Example 1. Adjust the electrolytic potential of No. 1 electrolytic cell to 1.8V, and the electrolytic current density to 1000A / m 2 , the electrolytic potential of No. 2 electrolytic cell is 2.5V, and the electrolytic current density is 1600A / m 2 .

[0065] Dissolve 2300g dipropyl adipate and 303g triethylamine in 2300g and 2300g propanol respectively to form feed solution A and feed solution B; feed feed solution A and feed solution B into the raw material mixer simultaneously for 10min and control Feeding speed, so that material liquid A, B complete feeding at the same time.

[0066] The mixed material is 2m 3 The feed rate of / h is pumped into the No. 1 electrolytic cell, so that t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com