Inflatable elevating agitator tank

A mixing barrel, aerated technology, applied in the directions of dissolution, solid separation, wet separation, etc., can solve the problems of insufficiently improving minerals, increasing the height difference of the slurry in the mixing barrel, reducing production efficiency, etc., to improve the effect time and The effect of reaction speed, guarantee of continuous industrial production, reduction of quantity and cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0008] The present invention will be further described below in conjunction with drawings and embodiments.

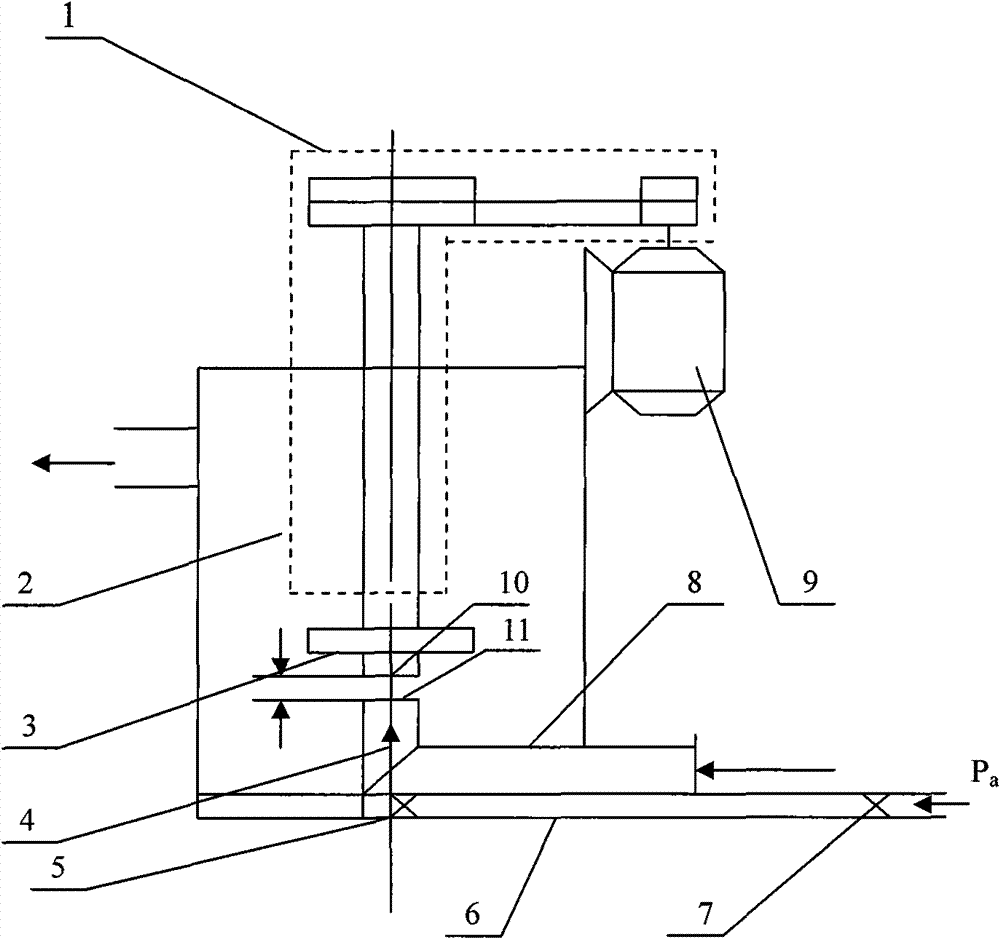

[0009] Such as figure 1 Shown is the cross-sectional view of the inflatable lifting mixing bucket provided by the present invention.

[0010] The inflatable lifting mixing drum provided by the present invention includes a motor 9 , a transmission device assembly 1 (shown by a dotted line in the figure), a lifting stirring impeller 3 and a stirring tank 2 . The above-mentioned transmission device assembly mainly includes a main shaft, one end of the main shaft has a main shaft pulley, and the other end is connected with the lifting agitating impeller 3 through the main shaft thread to form a vertical rotating shaft for lifting the agitating impeller 3; the motor 9 is provided with a motor pulley, which passes through the transmission belt Connect with the main shaft pulley of the transmission assembly. When the motor 9 works, the motor pulley on it drives the main shaf...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com