Dust-containing pipeline structure capable of effectively solving dust accumulation in pipe and design method thereof

A structural design and dust technology, applied in cleaning methods and utensils, chemical instruments and methods, and dust removal, etc., can solve the problems of difficult secondary opening and sinking, and achieve smooth opening, avoid dust sinking, and avoid being accumulated. dust crushing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

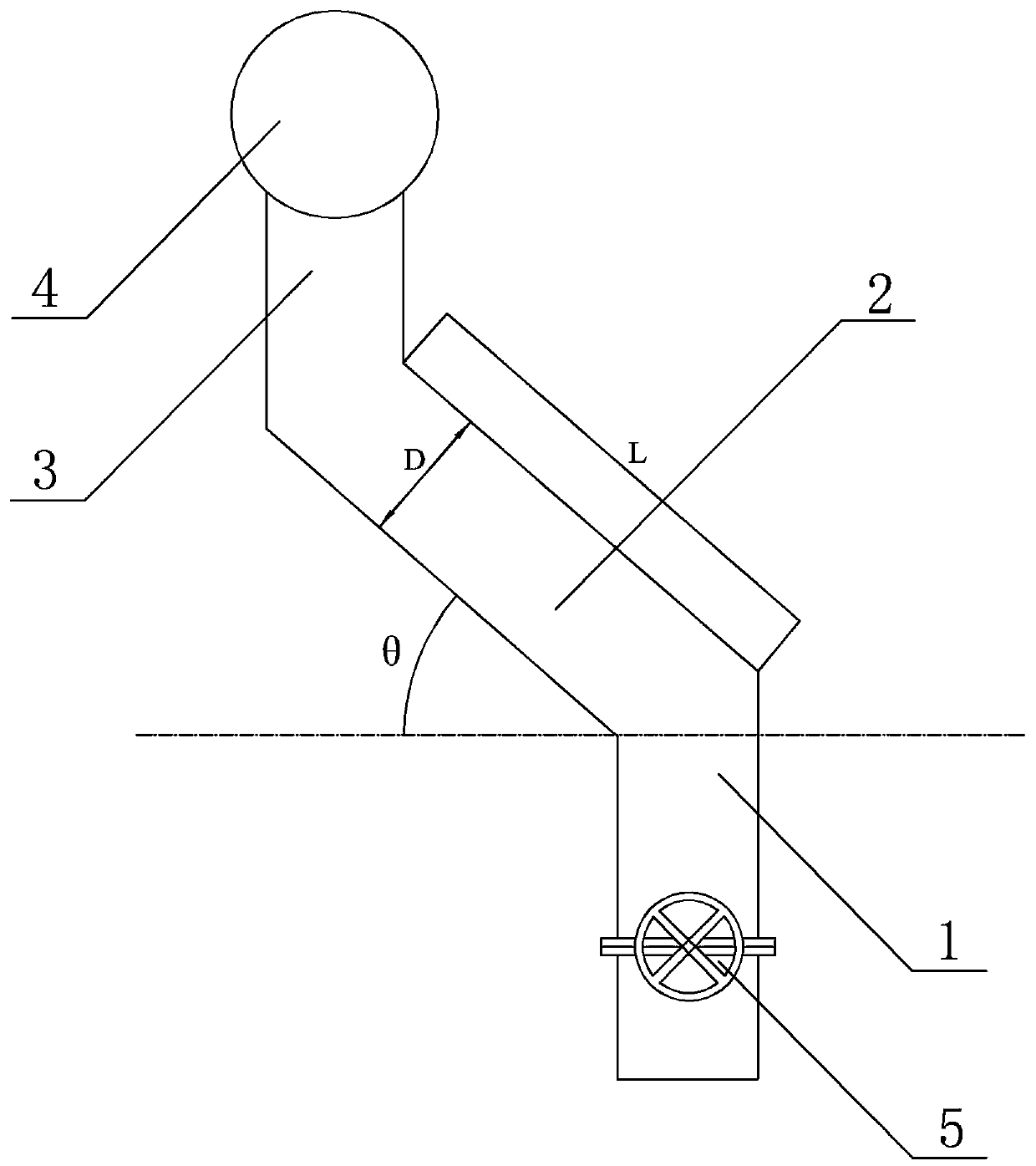

[0031] A method for designing a dust-containing pipeline structure that effectively solves the accumulation of dust in the pipeline, comprising the following steps:

[0032] 1) Measure the angle of repose a of the dust in the captured industrial waste gas at rest through existing experiments;

[0033] 2) The vertical auxiliary collection pipe connected to the horizontal main pipe in the dust removal and collection system is designed as a folded pipe, specifically including the first vertical auxiliary collection pipe where the airflow enters, and the second vertical auxiliary collection pipe connected to the horizontal main pipe. The header and the folded tube connected between them, the folded tube forms an angle θ with the horizontal plane; the folded tube is designed to ensure that the length L of the folded tube is greater than twice the diameter D of the folded tube, That is, L>2D;

[0034] 3) Ensure that the included angle θ>a+5°;

[0035] 4) Install a butterfly valve ...

Embodiment 2

[0037] A method for designing a dust-containing pipeline structure that effectively solves the accumulation of dust in the pipeline, comprising the following steps:

[0038] 1) Measure the angle of repose a of the dust in the captured industrial waste gas at rest through existing experiments;

[0039] 2) The vertical auxiliary collection pipe connected to the horizontal main pipe in the dust removal and collection system is designed as a folded pipe, specifically including the first vertical auxiliary collection pipe where the airflow enters, and the second vertical auxiliary collection pipe connected to the horizontal main pipe. The header and the folded tube connected between them, the folded tube forms an angle θ with the horizontal plane; the folded tube is designed to ensure that the length L of the folded tube is greater than twice the diameter D of the folded tube, That is, L>2D;

[0040] 3) Ensure that the included angle θ>a+8°;

[0041] 4) Install a butterfly valve ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com