A Method for Adjusting the Spinning Misalignment of Three Rotary Wheels

A three-rotary wheel and rotary wheel technology, applied in the field of mechanical processing, can solve the problems of cumbersome calculation process, poor stability, and poor scientific applicability, and achieve the effects of simple operation, avoiding deformation interference, and high efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

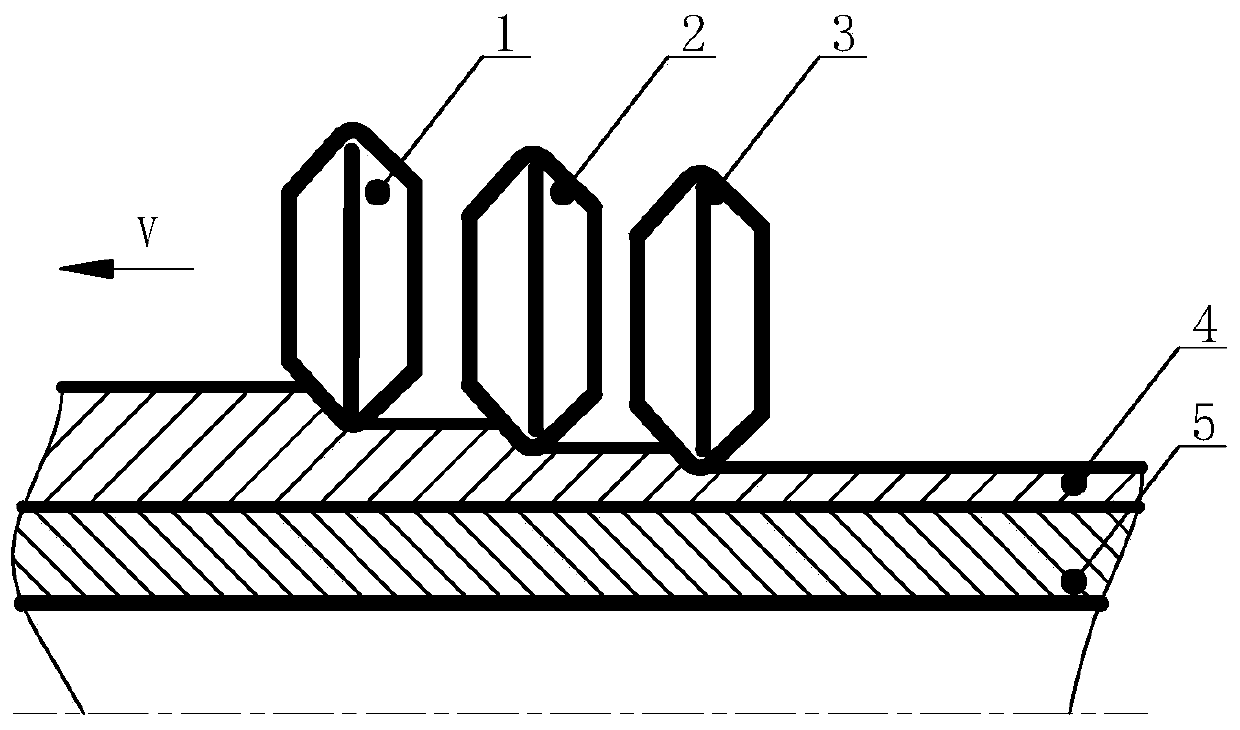

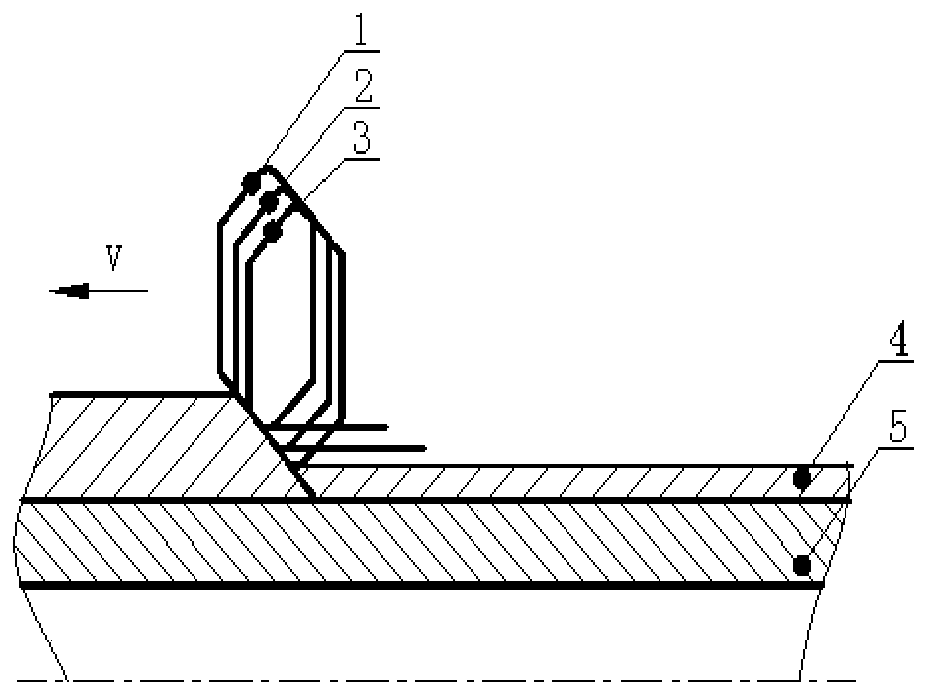

[0053] This embodiment is a method for adjusting the amount of spinning misalignment in processing ultra-high-strength steel thin-walled cylindrical parts by the three-wheel misalignment spinning method.

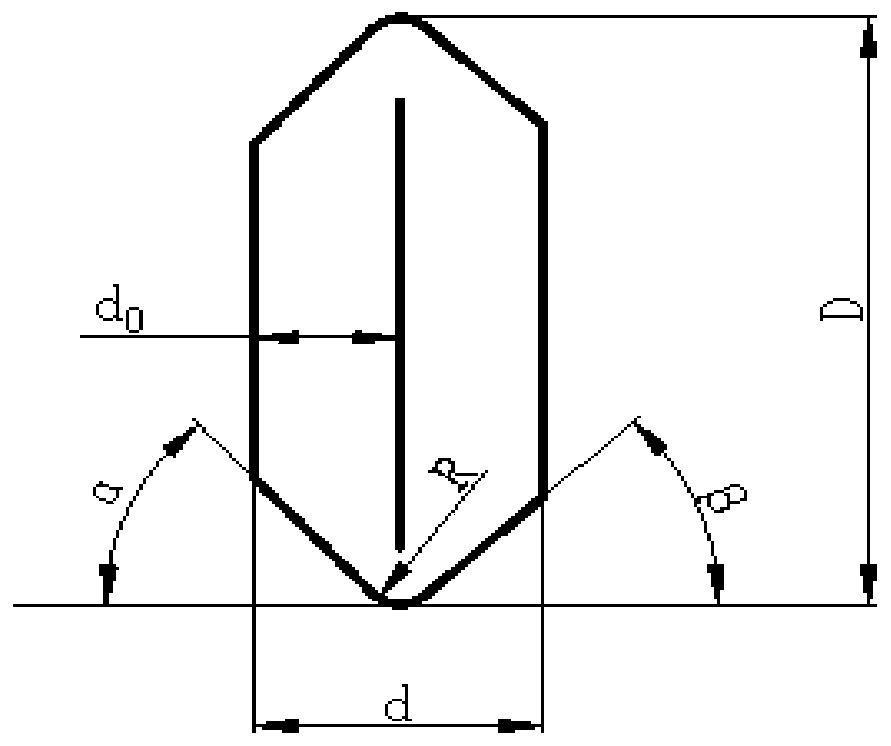

[0054] The structure of the rollers used in the processing is exactly the same, the number N of the rollers is 3, the diameter D of the rollers is 300mm, the thickness d of the rollers is 70mm, the angle of rotation α of the rollers is 30°, and the thickness of the end of the rollers is d 0 is 35mm, the exit angle β of the rotary wheel is 30°, and the fillet radius R of the rotary wheel is 6mm.

[0055] The concrete process of this embodiment is:

[0056] Step 1, determine the basic parameters of the wheel.

[0057] The number N of said rotary wheels is 3, and the structure of each rotary wheel is the same. The basic parameters of the rotary wheel include the rotary wheel diameter D, the rotary wheel thickness d, the rotary wheel screw-in angle α, the rotary wheel screw-in...

Embodiment 2

[0082] This embodiment is a method for adjusting the amount of spinning misalignment in processing ultra-high-strength steel thin-walled cylindrical parts by the three-wheel misalignment spinning method.

[0083] The structure of the rollers used in the processing is exactly the same, the number N of the rollers is 3, the diameter D of the rollers is 300mm, the thickness d of the rollers is 70mm, the angle of rotation α of the rollers is 30°, and the thickness of the end of the rollers is d 0 is 35mm, the exit angle β of the rotary wheel is 30°, and the fillet radius R of the rotary wheel is 6mm.

[0084] The concrete process of this embodiment is:

[0085] Step 1, determine the basic parameters of the wheel.

[0086] The number N of said rotary wheels is 3, and the structure of each rotary wheel is the same. The basic parameters of the rotary wheel include the rotary wheel diameter D, the rotary wheel thickness d, the rotary wheel screw-in angle α, the rotary wheel screw-in...

Embodiment 3

[0111] This embodiment is a method for adjusting the amount of spinning misalignment in processing ultra-high-strength steel thin-walled cylindrical parts by the three-wheel misalignment spinning method.

[0112] The structure of the rollers used in the processing is exactly the same, the number N of the rollers is 3, the diameter D of the rollers is 300mm, the thickness d of the rollers is 70mm, the angle of rotation α of the rollers is 30°, and the thickness of the end of the rollers is d 0 is 35mm, the exit angle β of the rotary wheel is 30°, and the fillet radius R of the rotary wheel is 6mm.

[0113] The concrete process of this embodiment is:

[0114] Step 1, determine the basic parameters of the wheel.

[0115] The number N of said rotary wheels is 3, and the structure of each rotary wheel is the same. The basic parameters of the rotary wheel include the rotary wheel diameter D, the rotary wheel thickness d, the rotary wheel screw-in angle α, the rotary wheel screw-in...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com