Cylindrical toothed tool and its processing technology

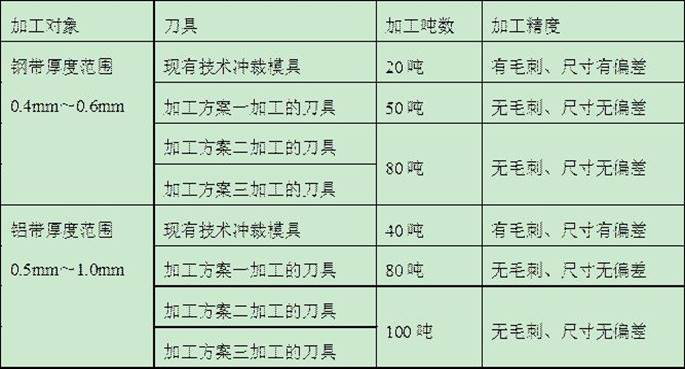

A technology of cylindrical teeth and processing technology, applied in the field of cylindrical toothed tools and their processing technology, can solve problems such as inability to feed materials, a large number of burrs in products, and reduce processing efficiency, to ensure consistency, improve dimensional accuracy and use Life and the effect of increasing the initial processing speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

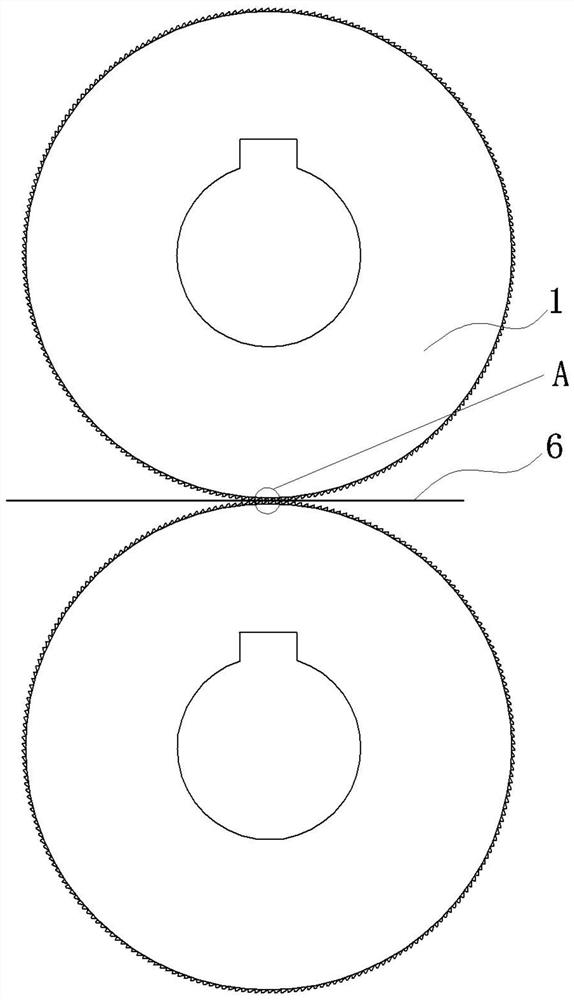

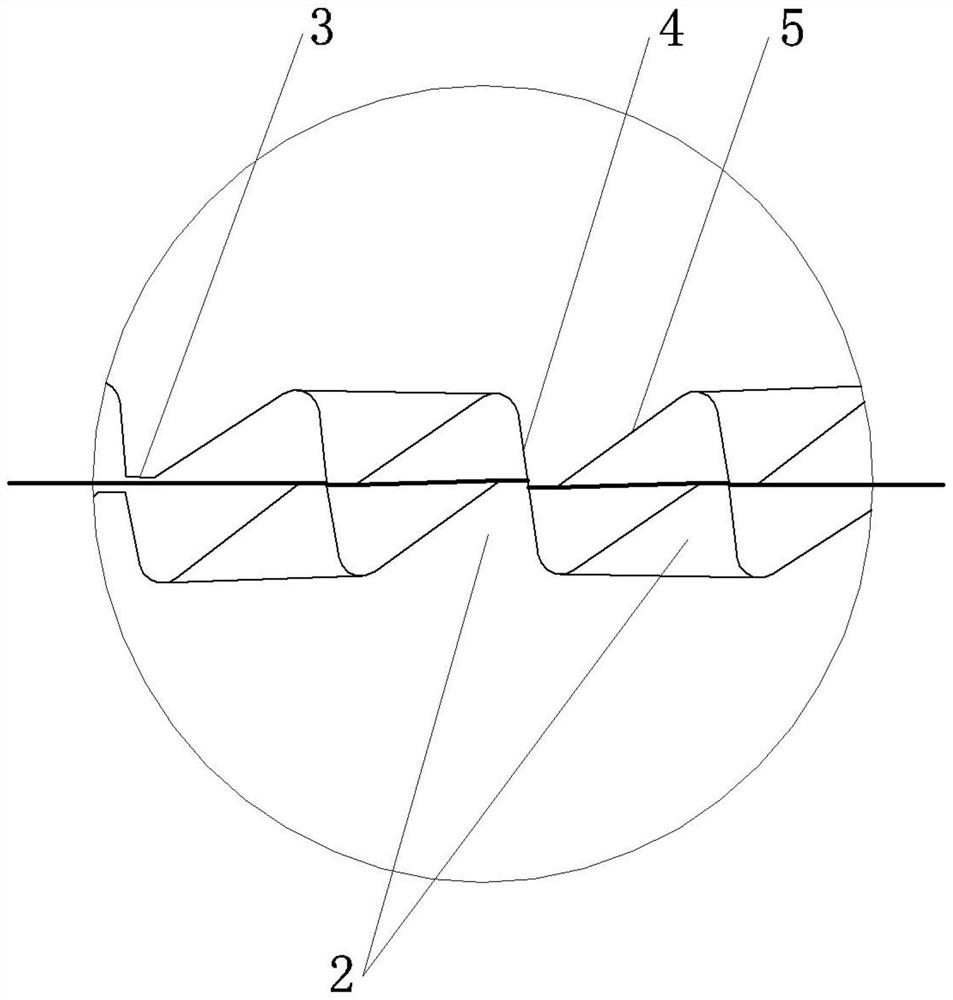

[0059] Below in conjunction with accompanying drawing and specific embodiment, the present invention is described in further detail: in the figure, 1 is a cylindrical toothed cutter, 2 is a cutter tooth, 3 is an addendum arc, 4 is a tooth surface, 5 is a tooth back, 6 For the strip.

[0060] Cylindrical toothed cutter and its processing technology,

[0061] Processing scheme one:

[0062] Step 1, prepare the forging blank of the cylindrical serrated tool:

[0063] (1) Size of the forging blank: the forging blank is a cuboid structure, and the machining allowance for the width W is 12 mm to 16 mm, preferably 14 mm; the length L is twice the width W; the machining allowance for the height H is 2 mm to 4mm, preferably 3mm. Since the cylindrical toothed tool is used in conjunction with two tools with the same structure, it can be guaranteed to be clamped on the slow wire-feeding device, and two cylindrical toothed tools can be processed at the same time. Improve processing eff...

PUM

| Property | Measurement | Unit |

|---|---|---|

| surface roughness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com