Trailer axle square fixing device, trailer axle and preparation method thereof

A sizing and axle technology is applied in the field of trailer axle sizing devices, which can solve the problems of low dimensional accuracy of square tubes and achieve the effect of being easy to implement.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

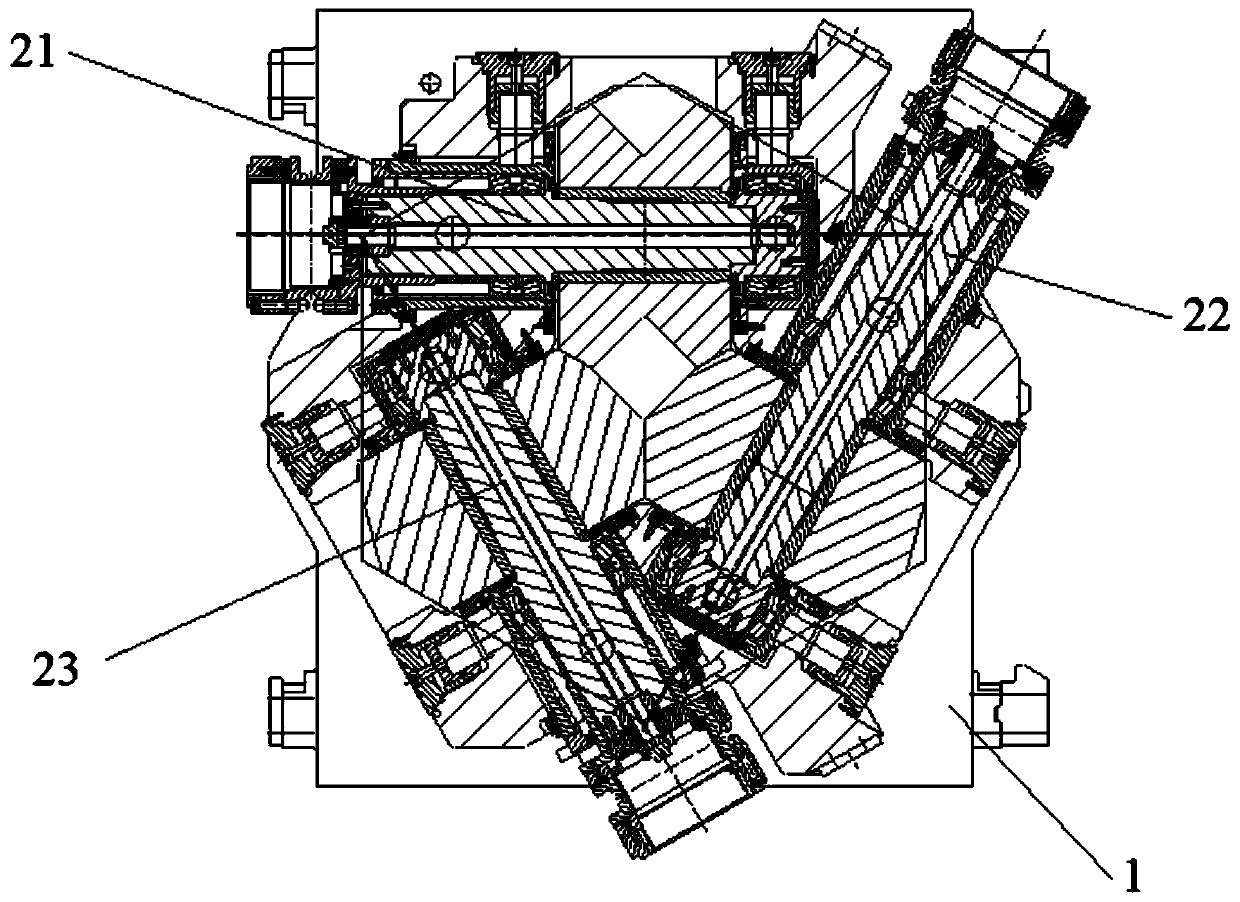

[0027] In another typical embodiment of the present application, a method for preparing a trailer axle is provided. The preparation method includes: heat-treating a steel slab to obtain a hot slab; performing hot piercing and rolling on the hot slab in sequence to obtain a slab tube; square the empty tube to obtain a square tube, and use any one of the above-mentioned trailer axle squaring devices to determine the square for the empty tube.

[0028]Compared with cold-deformed square tubes, hot-rolled square tubes have the advantages of larger cross-sectional area, smaller inner and outer rounded corners, and reasonable distribution of geometric dimensions of the same variety and specification, and have better bearing capacity; Small stress, better low-temperature impact performance, and lower ductile-brittle transition temperature. The square tube produced by cold deformation has a greater possibility of brittle cracking due to the limitation of the process. It is necessary to...

Embodiment 1

[0040] The weight percentage of each chemical element in the square tube material for trailer axle used in low temperature environment is: C 0.19~0.23, Si 0.20~0.37, Mn 1.55~1.68, V 0.04~0.07, Nb 0.030~0.050, Al 0.020~0.040, Ni 0.18~0.28, the balance is Fe and unavoidable impurities.

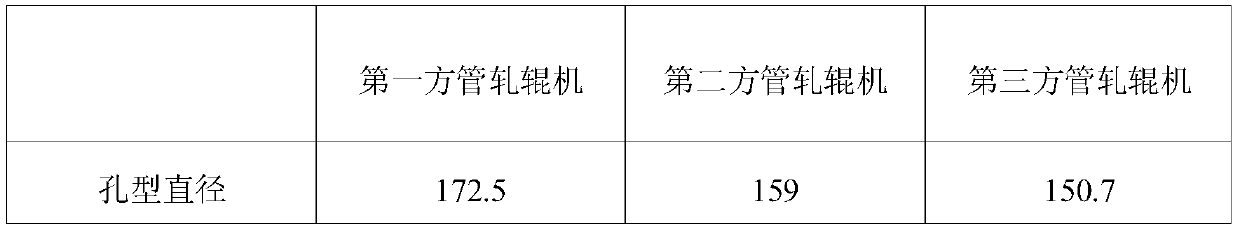

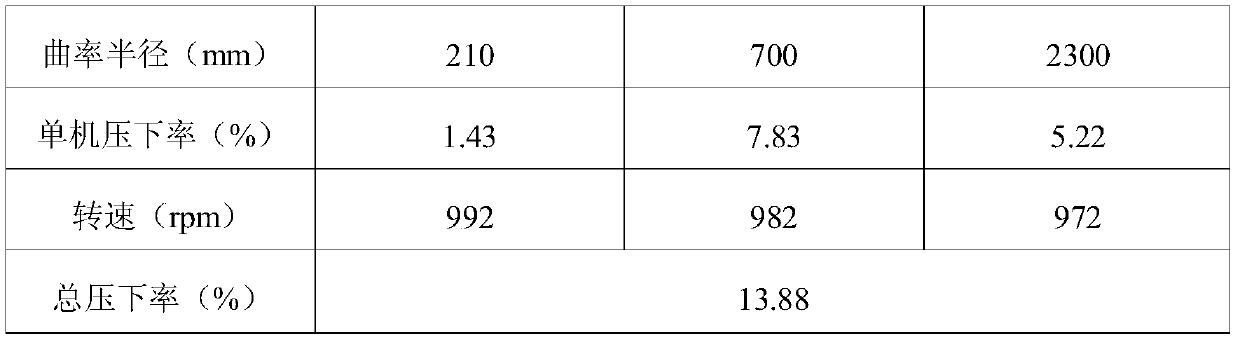

[0041] Taking the production of a square tube with a size of 150×150×11mm as an example, the specific steps are as follows:

[0042] A. Produced by Ф250mm billet. Billet heating is divided into preheating, heating and soaking process. The preheating temperature depends on the furnace temperature; the heating is divided into five stages: the heating stage temperature is 900°C±10°C, the heating stage temperature is 1030°C±10°C, the heating stage temperature is 1150°C±10°C, and the fourth and fifth stage temperatures are 1260°C ±10°C; soaking section temperature 1250°C±10°C, total heating time 2-2.5 hours.

[0043] B. The rolled tube is pierced by a conical piercer and rolled by a continuous tub...

Embodiment 2

[0050] The difference from Example 1 is that the weight percentages of the chemical elements in the square tube material for trailer axles are: C 0.19-0.23, Si 0.20-0.37, Mn 1.55-1.68, V 0.04-0.07, Nb 0.030-0.050, Al0 .020~0.040, Ni 0.5~0.75, the balance is Fe and unavoidable impurities.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com