Temperature automatic regulating and controlling device for short-cut resin-based fiber reinforced plastic prepreg forming process

A fiber reinforced plastic and molding technology, which is applied in the field of resin-based fiber reinforced plastic prepreg extrusion molding, can solve the problems of insufficient mechanical performance indicators, affecting product appearance and quality, and insufficient product functions, and achieves increased use. Scope, usefulness, and simple effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

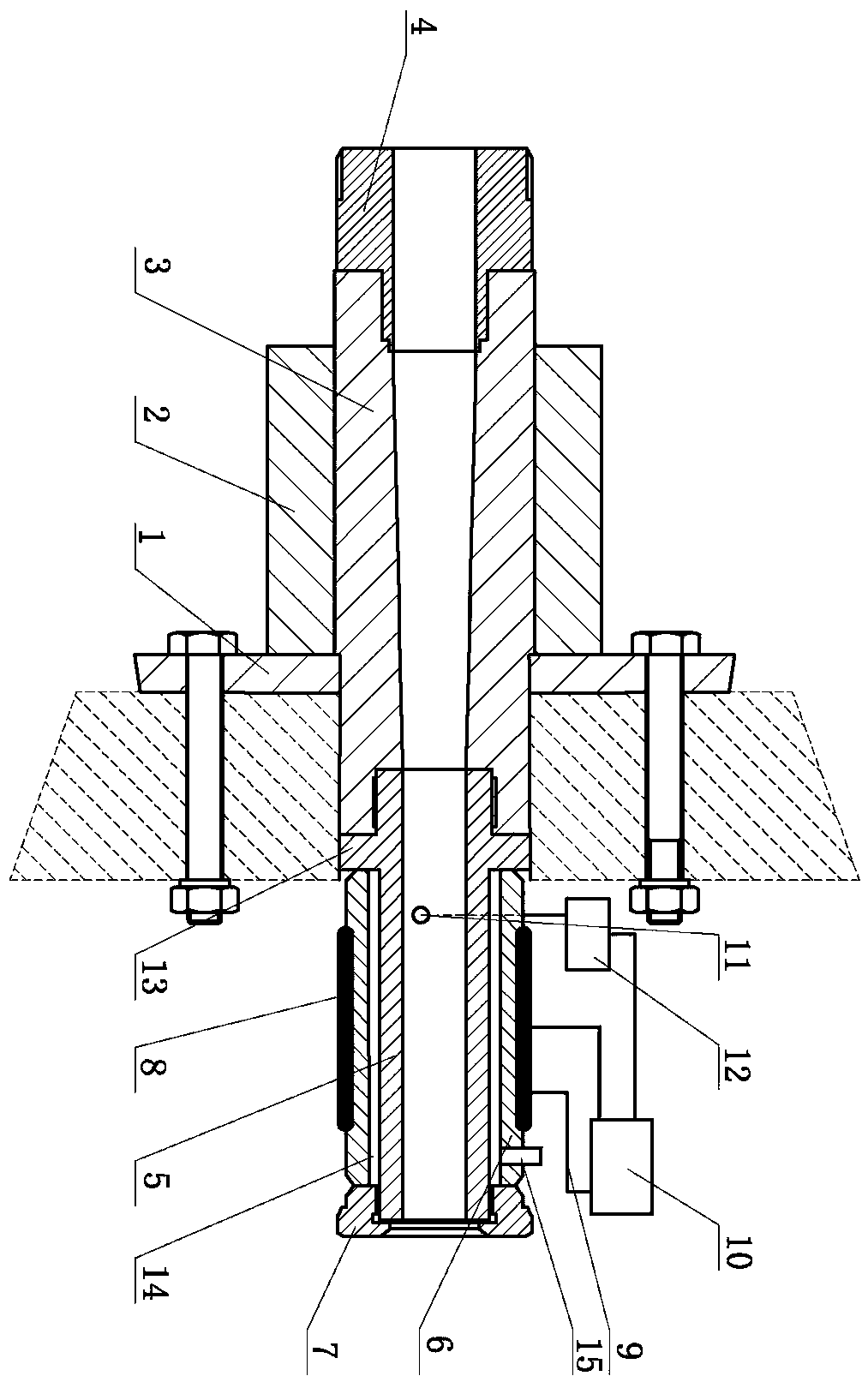

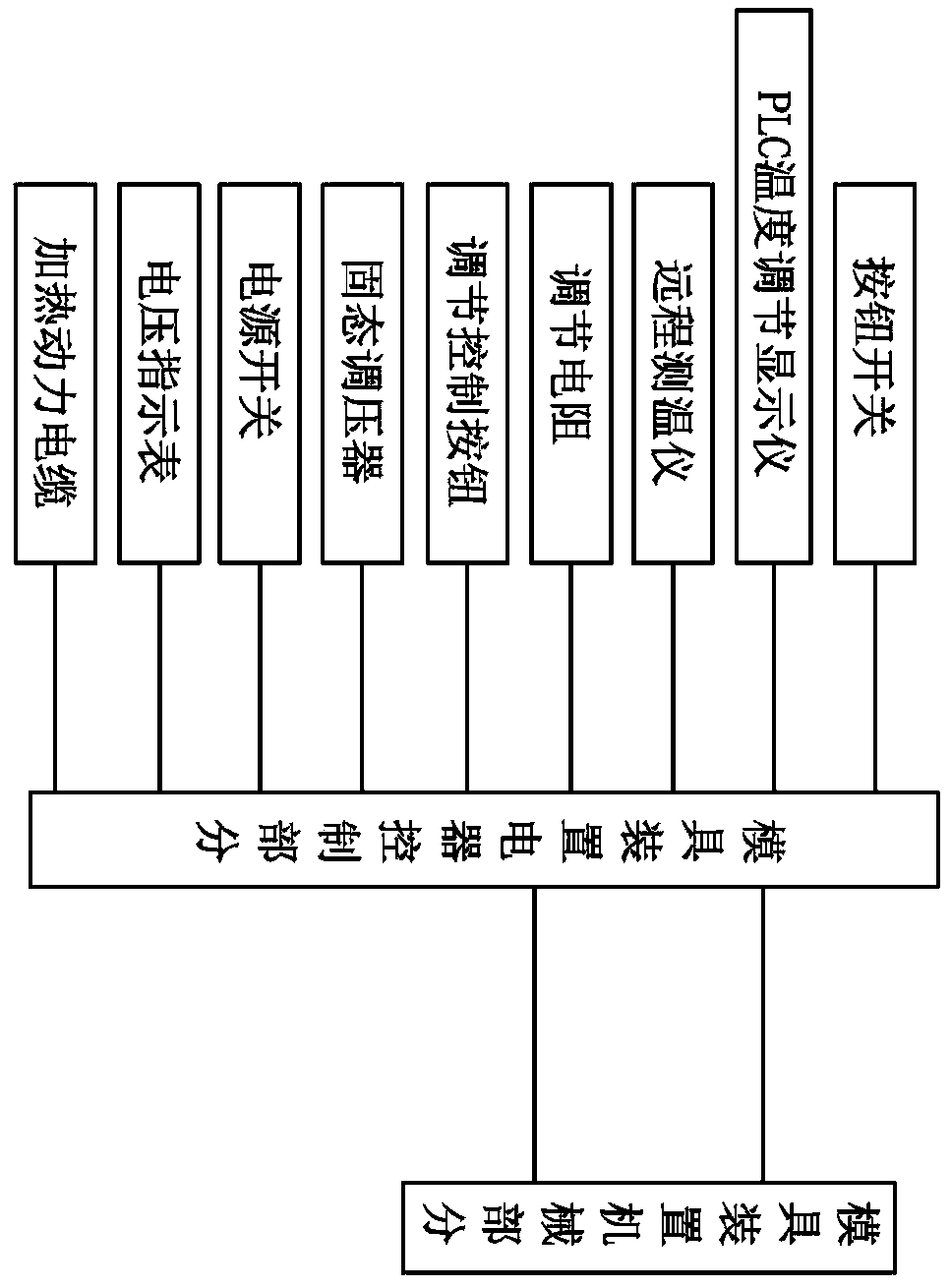

[0009] An automatic temperature control device for a molding process of chopped resin-based fiber-reinforced plastic prepreg according to the present invention, such as figure 1 As shown, including the mechanical structure part and the electrical control part, the temperature control system formed by the mechatronic design of electrical components and mechanical devices and digital technology enables the temperature parameters in the production process to be controlled at the temperature required by the product technical documents. Within the scope, precise control in the production process is realized. The mechanical mechanism part includes a connection plate 1, the connection plate 1 can be connected with the seat body of the punching equipment through fixing bolts, and a mold sleeve 2 is fixedly connected to one side of the connection plate 1, and the mold sleeve 2 makes the overall mold device and The installation position of the equipment is reliable and stable. The mold ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com