Storage method and system for pallet-intensive warehouse combined with pallet beam shelf

A technology of dense storage and pallets, which is applied in the field of storage and distribution of pallet-intensive storage combined with pallet beam shelves, can solve problems that affect storage density and storage efficiency, are not suitable for multi-product regulations, small batch storage, investment and storage costs increase, etc. , to achieve the effect of reducing the number of tail-end handling, good economic performance, and improving operating efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

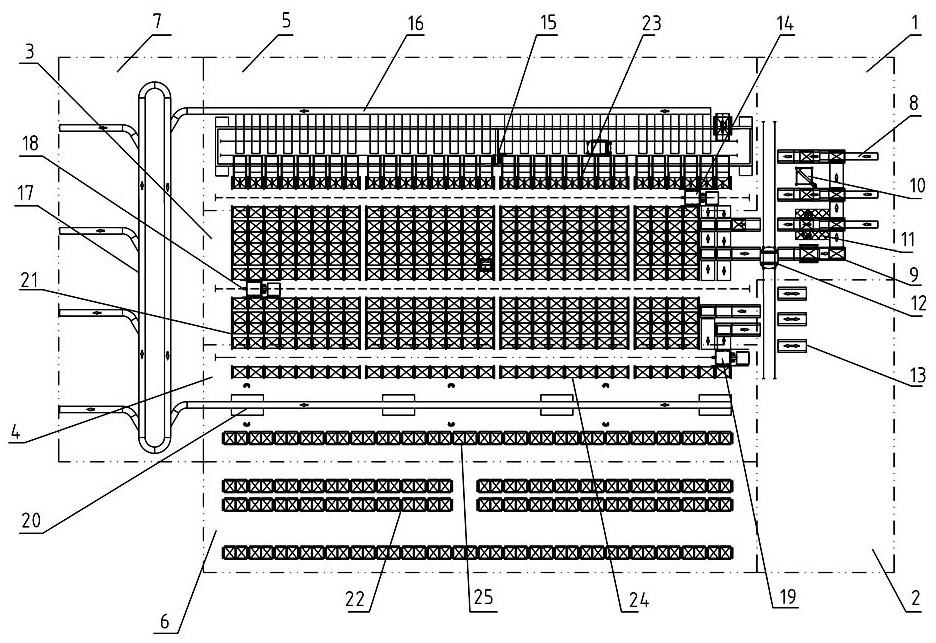

[0027] The embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings. This embodiment is implemented on the premise of the technical solution of the present invention, and detailed implementation methods and specific operating procedures are provided, but the scope of protection of the present invention is not limited to the following Described embodiment.

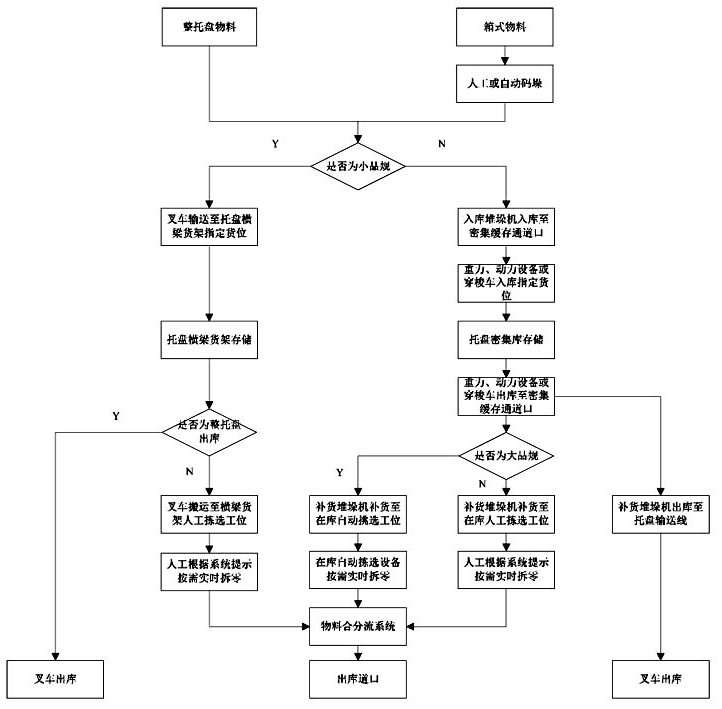

[0028] like figure 1 , 2 As shown, the method for storing and dividing the pallet-intensive warehouse of the present invention in conjunction with the pallet crossbeam shelf is carried out according to the following steps:

[0029] Step 1. After the incoming material is identified by information, it is judged whether it is a small product;

[0030] Step 2. After the large and medium-sized pallet materials are transported to the pallet conveying line 9 by a forklift, they are transported to the storage port of the pallet-intensive storage unit 3 by scanning codes;...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com