Preparation method of Cu-based two-dimensional sheet mofs material

A flake-like, amino-terephthalic acid technology, applied in the field of metal-organic framework material preparation, can solve the problems of high experimental equipment, low catalytic performance, difficulty in large-scale production, etc., to achieve increased contact area, simple preparation method, The effect of short experimental period

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] In order to test the effect of the ratio of metal ions and ligands on the morphology of MOFs materials, the experiment was carried out by the control variable method. The specific steps are:

[0031] Add Cu(NO 3 ) 2 ·3H 2 O stirred until completely dissolved, then added ligand 2-aminoterephthalic acid, 2-aminoterephthalic acid and Cu(NO 3 ) 2 ·3H 2 The molar ratio of O is 0.5:1, Cu(NO 3 ) 2 ·3H 2 The molar concentration of O is 0.005 mol / L. Stir for 30 minutes to mix the two evenly, then move the solution to a polytetrafluoroethylene reactor, and after installation, let it stand at 120°C for 24 hours. After the reactor was taken out and cooled to room temperature naturally, it was centrifuged at 6000r / min for 3min, and the supernatant was discarded to obtain a blue-green precipitate.

[0032] Add DMF to wash the blue-green precipitate, add 1 mL of DMF to each 1 mg of precipitate, sonicate for 10 min, centrifuge at the same speed for 3 min, and discard the supe...

Embodiment 2-3

[0034] Other steps are the same as in Example 1, and the difference is that the amount of the ligand (2-aminoterephthalic acid) added is different, and the ligand and Cu(NO 3 ) 2 ·3H 2 The molar ratio of O is 1:1 and 1.5:1 in turn. The obtained MOFs materials are marked as No. 2 and No. 3 after drying.

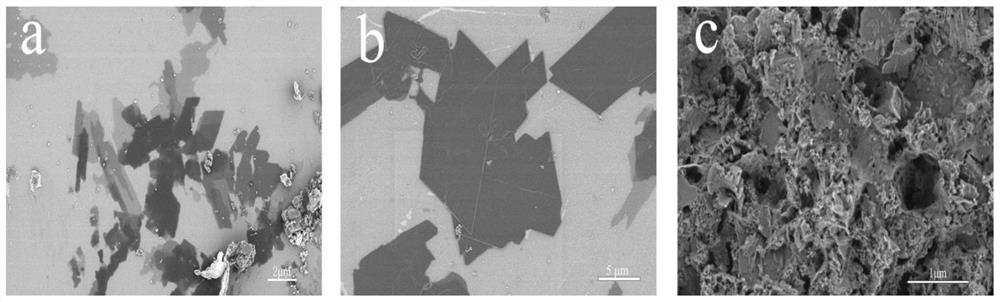

[0035] figure 1 a, figure 1 b, figure 1 c is the corresponding Cu(BDC-NH 2 ) SEM image of MOFs material, it can be seen that figure 1 The flake structure in b is more regular, and the flake diameter is about 8 μm. Therefore, Cu(NO 3 ) 2 ·3H 2 The optimum molar ratio of O to ligand is about 1:1. When the ligand ratio decreases, the formed flakes are smaller, about 2 μm. When the proportion of ligands increases, the increase of ligands makes the lamellar structure tightly combined and affects the lamellar separation. Therefore, suitable ligands with Cu(NO 3 ) 2 ·3H 2 The ratio of O molar weight is the 2 ) important conditions for MOFs materials.

Embodiment 4-6

[0037] In order to explore the relationship between 2-aminoterephthalic acid and Cu(NO 3 ) 2 ·3H 2 The molar concentration of O for Cu(BDC-NH 2 ) of MOFs material morphology, our implementation steps are as follows:

[0038] Add Cu(NO 3 ) 2 ·3H 2 O was stirred until completely dissolved, and the added 2-aminoterephthalic acid and Cu(NO 3 ) 2 ·3H 2 The molar ratio of O is 1:1. Cu(NO 3 ) 2 ·3H 2 The molar concentration of O is 0.001mol / L, 0.005mol / L, and 0.010mol / L in turn. Other steps are with embodiment 1. After drying, measure SEM to observe the morphology. Mark them as samples 4, 5, and 6 in turn.

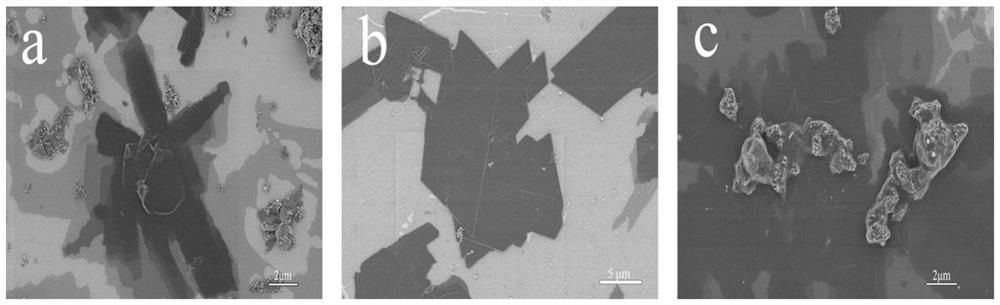

[0039] figure 2 a, figure 2 b, figure 2 c are the corresponding Cu(BDC-NH 2 ) of the MOFs material, it can be seen that the sheet structure in sample No. 5 is more regular and the edges are smoother, so the added Cu(NO 3 ) 2 ·3H 2 The optimum molar concentration of O and 2-aminoterephthalic acid is about 0.005mol / L. When the concentration decreases, the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| decomposition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com