A kind of drag chain cable sheath material specially used for robots and its preparation method

A drag chain cable and sheath material technology, applied in the direction of organic insulators, plastic/resin/wax insulators, etc., can solve the complex steps of graphene oxide modification, unsatisfactory heat resistance and oil resistance, impact resistance and processing Poor performance and other problems, to achieve the effect of excellent crack resistance, aging resistance and good flame retardancy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

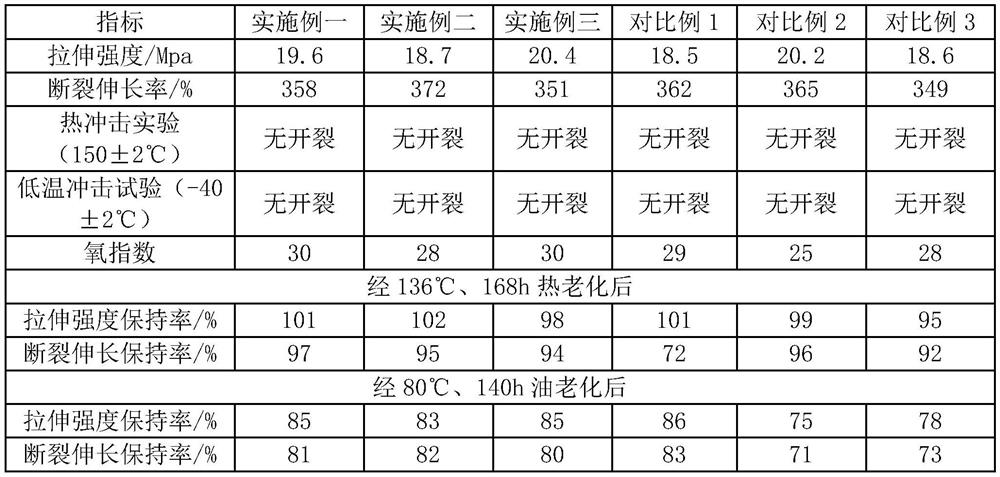

Examples

Embodiment 1

[0034] Embodiment 1 robot-specific towline cable sheath material

[0035] Cable sheath materials for drag chains for robots, including the following raw materials and their mass percentages: 37.58% polyvinyl chloride resin, 6.02% thermoplastic polyurethane elastomer rubber, 3.01% nitrile rubber, 31.95% polyester plasticizer, and 15.04% filler , stabilizer 3.01%, antioxidant 0.15%, composite flame retardant 3%, lubricant 0.24%; the average degree of polymerization of polyvinyl chloride resin is 2500, polyester plasticizer is UN380, filler is magnesium hydroxide, The composite flame retardant is composed of antimony trioxide and nano-montmorillonite in a mass ratio of 5:3, the stabilizer is calcium zinc stabilizer, and the antioxidant is β-(3,5-di-tert-butyl-4-hydroxy Phenyl) n-octadecanyl propionate, the lubricant is polyethylene wax.

[0036] The preparation method of the drag chain cable sheath material specially used for the robot comprises the following steps:

[0037] S1 W...

Embodiment 2

[0040] Embodiment 2 Special towline cable sheath material for robots

[0041] Cable sheath materials for drag chains for robots, including the following raw materials and their mass percentages: 36.25% polyvinyl chloride resin, 5.8% thermoplastic polyurethane elastomer rubber, 2.9% nitrile rubber, 33.2% polyester plasticizer, and 14.8% filler , stabilizer 3.2%, antioxidant 0.27%, composite flame retardant 3.3%, lubricant 0.28%; the average degree of polymerization of polyvinyl chloride resin is 2500, polyester plasticizer is UN380, filler is magnesium hydroxide, The composite flame retardant is composed of antimony trioxide and nano-montmorillonite in a mass ratio of 3:2, the stabilizer is calcium zinc stabilizer, and the antioxidant is β-(3,5-di-tert-butyl-4-hydroxy Phenyl) n-octadecanyl propionate, the lubricant is stearic acid.

[0042] The preparation method of embodiment two is the same as embodiment one.

Embodiment 3

[0043] Embodiment 3 special towline cable sheath material for robots

[0044] Cable sheath material for drag chains for robots, including the following raw materials and their mass percentages: 40% polyvinyl chloride resin, 6.4% thermoplastic polyurethane elastomer rubber, 3.2% nitrile rubber, 30.2% polyester plasticizer, and 15.5% filler , stabilizer 2%, antioxidant 0.2%, composite flame retardant 2.3%, lubricant 0.2%; the average degree of polymerization of polyvinyl chloride resin is 2500, polyester plasticizer is UN380, filler is magnesium hydroxide, The composite flame retardant is composed of antimony trioxide and nano-montmorillonite in a mass ratio of 5:3, the stabilizer is calcium zinc stabilizer, and the antioxidant is β-(3,5-di-tert-butyl-4-hydroxy Phenyl) n-octadecanyl propionate, the lubricant is polyethylene wax.

[0045] The preparation method of embodiment three is the same as embodiment one.

PUM

| Property | Measurement | Unit |

|---|---|---|

| degree of polymerization | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com