A rubber asphalt modifier improving asphalt performance and application thereof

A technology of rubber asphalt and modifier, applied in the field of asphalt modifier preparation, can solve problems such as application introduction in the field of road asphalt, uneven mixing of mixtures, limited applicability range, etc., to improve anti-reflection cracks and Anti-fatigue ability, prevent asphalt segregation, improve the effect of storage stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Example Embodiment

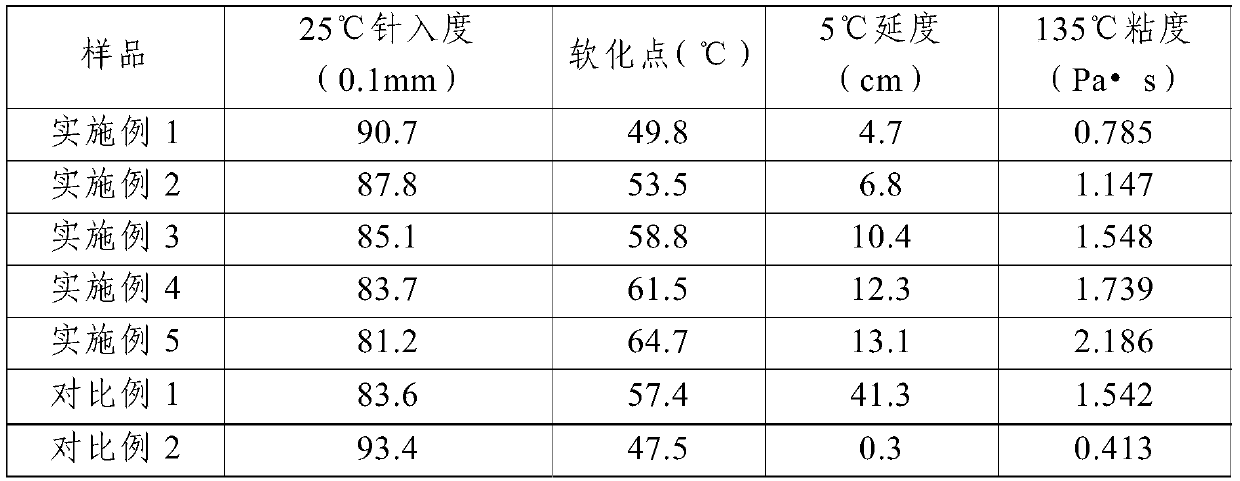

[0030] Example 1

[0031] The rubber asphalt modifier for enhancing asphalt performance in this embodiment is made of the following parts by mass of raw materials: 20 parts of soft base asphalt, 57 parts of modified rubber powder, and 15 parts of modified conglomerate powder; The soft base asphalt is No. 90 base asphalt;

[0032] The preparation methods of the modified rubber powder and the modified conglomerate powder both include the following steps:

[0033] Step 1: Pre-cleaning the surface of rubber powder and conglomerate powder to remove oil and impurities, and then drying; the particle size of the rubber powder is 400 μm to 600 μm, and the particle size of the conglomerate powder is 300 μm to 600 μm;

[0034] Step 2. Place the dried rubber powder and conglomerate powder in the double-cathode plasma sputtering deposition furnace in the tray of the double-cathode plasma sputtering deposition furnace respectively. Select Ti with a mass purity of 99.9% as the target material, and u...

Example

[0038] Example 2 ~ Example 5

[0039] The difference between Example 2 to Example 5 and Example 1 is that in the preparation method of modified asphalt, the added amount of rubber asphalt modifier to enhance asphalt performance corresponds to 10%, 15%, and 10% of the mass of the base asphalt, respectively. 20%, 25%.

Example Embodiment

[0068] Example 6

[0069] The rubber asphalt modifier for enhancing asphalt performance in this embodiment is made of the following parts by mass of raw materials: 30 parts of soft base asphalt, 68 parts of modified rubber powder, and 25 parts of modified conglomerate powder; The soft base asphalt is No. 90 base asphalt;

[0070] The preparation methods of the modified rubber powder and the modified conglomerate powder both include the following steps:

[0071] Step 1: Pre-cleaning the surface of rubber powder and conglomerate powder to remove oil and impurities, and then drying; the particle size of the rubber powder is 400 μm to 600 μm, and the particle size of the conglomerate powder is 300 μm to 600 μm;

[0072] Step 2. Place the dried rubber powder and conglomerate powder in the double-cathode plasma sputtering deposition furnace in the tray of the double-cathode plasma sputtering deposition furnace respectively. Select Ti with a mass purity of 99.9% as the target material, and u...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com