Preparation method of preparing Janus structure nano-fiber through single-axis electrostatic spinning

A technology of electrospinning and nanofibers, which is applied in fiber processing, textile and papermaking, filament/thread forming, etc., to achieve the effects of wide practicability, simple preparation and convenient operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

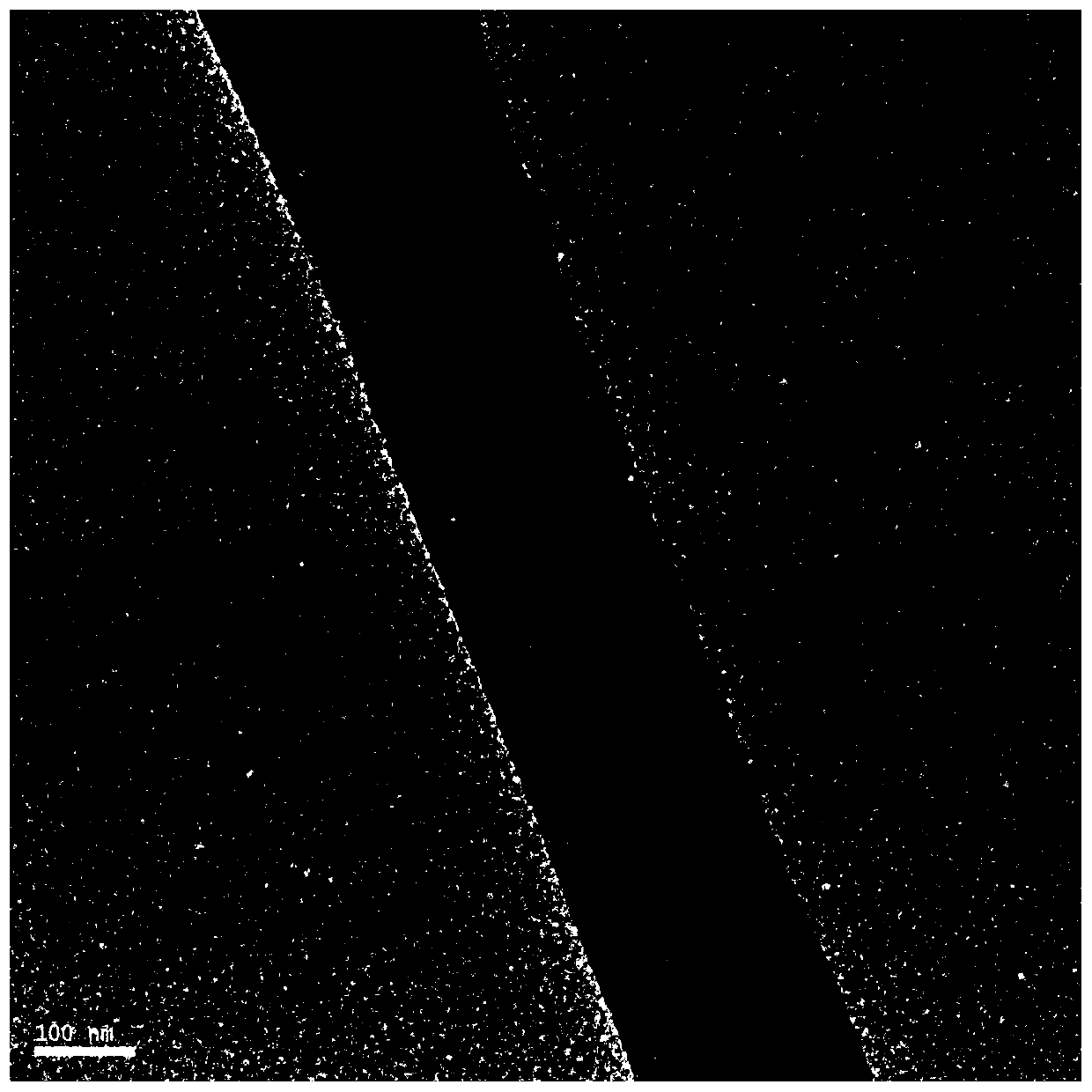

[0033] The embodiment of the present invention provides a method for preparing a Janus structure nanofiber membrane by uniaxial electrospinning technology. The specific operation steps include: jointly dissolving PVP and PCL in N, N-dimethyl In the formamide and chloroform solvents, the mass fraction of PVP is 4.5 wt%, and the mass fraction of PCL is 4.5 wt%, and magnetically stirred for a period of time until dissolved, and the layers are separated after standing.

[0034] Add the spinning solution obtained above into the propulsion syringe, and control the electrospinning parameters such as voltage and propulsion speed. After the solution in the syringe is stratified, electrospinning is carried out, and the electrospinning is continued and stable for a period of time to obtain a complete single Nanofibrous membranes with root Janus structures. The specific operating parameters of electrospinning are: the spinning voltage is 17kV, the distance from the spinneret to the receiv...

Embodiment 2

[0036] The embodiment of the present invention provides a method for preparing a Janus structure nanofiber membrane by uniaxial electrospinning technology. The specific operation steps include: jointly dissolving PVP and PCL in N, N-dimethyl In the formamide and chloroform solvents, the mass fraction of PVP is 1.8 wt%, and the mass fraction of PCL is 9.1 wt%, and magnetically stirred for a period of time until dissolved, and the layers are separated after standing.

[0037] Add the spinning solution obtained above into the propulsion syringe, and control the electrospinning parameters such as voltage and propulsion speed. After the solution in the syringe is stratified, electrospinning is carried out, and the electrospinning is continued and stable for a period of time to obtain a complete single Nanofibrous membranes with root Janus structures. The specific operating parameters of electrospinning are: the spinning voltage is 17kV, the distance from the spinneret to the receiv...

Embodiment 3

[0039] The embodiment of the present invention provides a method for preparing a Janus structure nanofiber membrane by uniaxial electrospinning technology, and the specific operation steps include: jointly dissolving 6.8wt% PVP and 2.3wt% PCL in N with a mass ratio of 1:4 , in N-dimethylformamide and chloroform solvents, the mass fraction of PVP is 6.8wt%, and the mass fraction of PCL is 2.3wt%. Stir magnetically for a period of time until dissolved, and stand to separate into layers.

[0040] Add the spinning solution obtained above into the propulsion syringe, and control the electrospinning parameters such as voltage and propulsion speed. After the solution in the syringe is stratified, electrospinning is carried out, and the electrospinning is continued and stable for a period of time to obtain a complete single Nanofibrous membranes with root Janus structures. The specific operating parameters of electrospinning are: the spinning voltage is 17kV, the distance from the spi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com