Automatic folding, loading and unloading transportable parking apron

An apron and automatic technology, applied in the aviation field, can solve the problems of temporary aprons that cannot be set up with fixed structures, large expansion area, and few operators, so as to reduce safety hazards, large size area, and product demand. huge effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

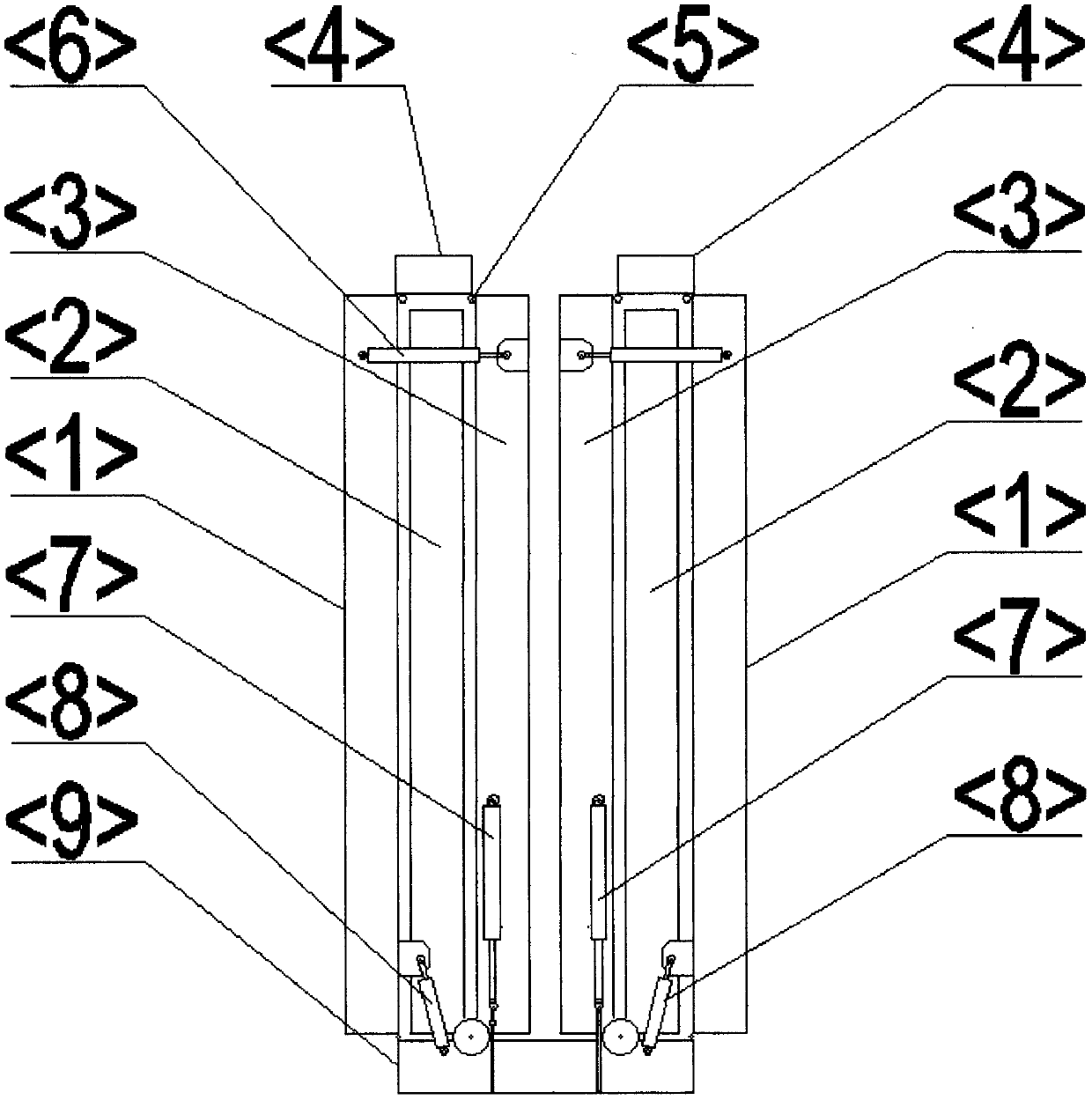

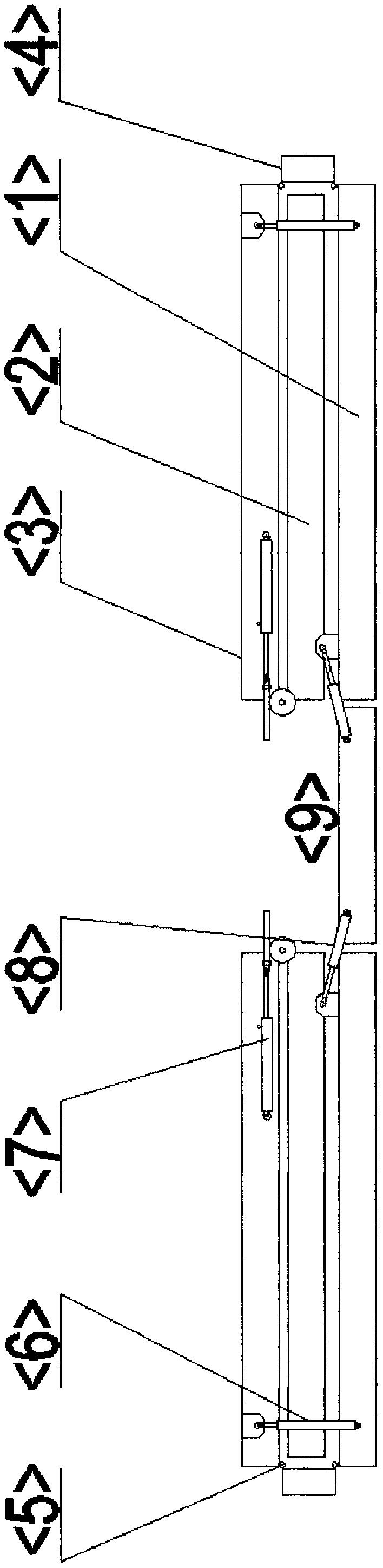

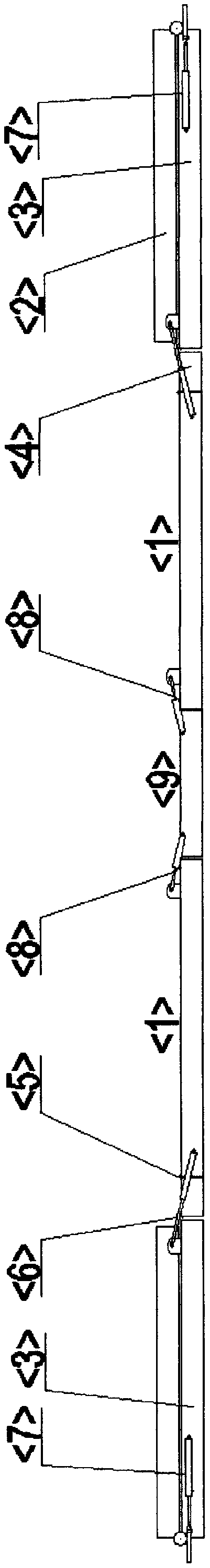

[0032] Embodiment: the present invention provides a kind of automatic foldable loading and unloading transportable apron, please refer to Figure 1-Figure 13 .

[0033] The present invention also provides a method for implementing an automatic folding loading and unloading transportable apron:

[0034] Specifically, the automatic folding loading and unloading transportable apron provided in this embodiment is installed on a four-wheel trailer, and the tractor provides transportation power, hydraulic pressure, and electricity, and the hydraulic control group is installed on the apron carrier vehicle.

[0035] Specifically, in the automatic folding loading and unloading transportable apron provided in this embodiment, the carrier vehicle is provided with a power supply interface and a hydraulic pipeline interface.

[0036] Specifically, for the automatic folding, loading and unloading transportable apron provided in this embodiment, the turning mechanism is a hydraulic cylinder...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com