Intelligent separate injection fixed threshold control layered flow allocation method

An intelligent, high-flow technology, applied in the direction of mining fluid, earthwork drilling, wellbore/well components, etc., can solve the problems of heavy survey and adjustment workload, rapid decline in inspection and matching qualification rate, and frequent obstructions in survey and adjustment, achieving Reduce operational risks and costs, overcome the inability to calibrate, and ensure accurate measurement effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

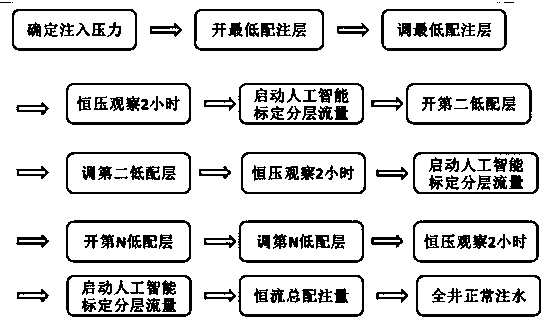

[0035] A layered flow allocation method for an intelligent pipe string, characterized in that it comprises the following steps:

[0036] Step 1, sending a first instruction, the first instruction is to open the intelligent water distributor on the lowest distribution level, and close the intelligent water distributor on the layer outside the lowest distribution level;

[0037] Step 2: Send an instruction to adjust the opening of the smart water distributor at the lowest distribution level;

[0038] Step 3: Obtain the real-time flow rate of the surface flowmeter. At this time, the real-time flow rate of the surface flowmeter is equal to the real-time flow rate of the smart water distributor at the lowest distribution level. Compare the real-time flow rate of the smart water distributor at the lowest distribution level with the design configuration of the lowest distribution level. The relationship between injection volume;

[0039] Step 4, if the real-time flow rate of the int...

Embodiment 2

[0083] This embodiment is improved on the basis of Embodiment 1. Before the first step, a trial injection is performed to determine the dispensing pressure for measurement and adjustment.

[0084] The dispensing pressure mentioned above is the reference value of the dispensing amount of each layer corresponding to the injection pressure when measuring and adjusting the dispensing.

[0085] During the test injection, the multi-layer combined injection method is adopted, all the water distributors of each layer are fully opened, and the constant flow control of the ground controller is used. The sum of the design charge of all the layers of the column.

[0086] During the test injection, the multi-layer injection method is adopted, all the water distributors of each layer are fully opened, and the constant flow control of the ground controller is used to control the sum of the actual water injection volumes of all distribution layers of the intelligent pipe string. 120-140% of ...

Embodiment 3

[0117] Such as figure 1 Shown, it is improved on the basis of embodiment 1 and embodiment 2,

[0118] The steps 1 to 15 are based on the digital intelligent dispensing of fluid wave code communication, and realize the sending and operation of deployment instructions from the ground to the underground through the control software by means of wave code communication on the ground.

[0119] The present invention is based on the digital intelligent dispensing of fluid wave code communication, and realizes the sending and operation of deployment instructions from the ground to the underground through the control software on the ground by means of wave code communication. The operation is simple and the accuracy is high, which overcomes the problem that the downhole flow rate cannot be calibrated in the downhole. At the same time, it eliminates the need to go to the test vehicle for cable or steel wire fishing test deployment in the conventional injection process, ensuring long-term...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com