Intelligent downhole flow calibration method of separate injection standard meter

A calibration method and standard table technology, which is applied in the directions of measurement, production fluid, earthwork drilling and production, etc., can solve the problem that the downhole flow rate cannot be calibrated, and achieve the effect of reducing operation risk and cost, improving accuracy and high accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

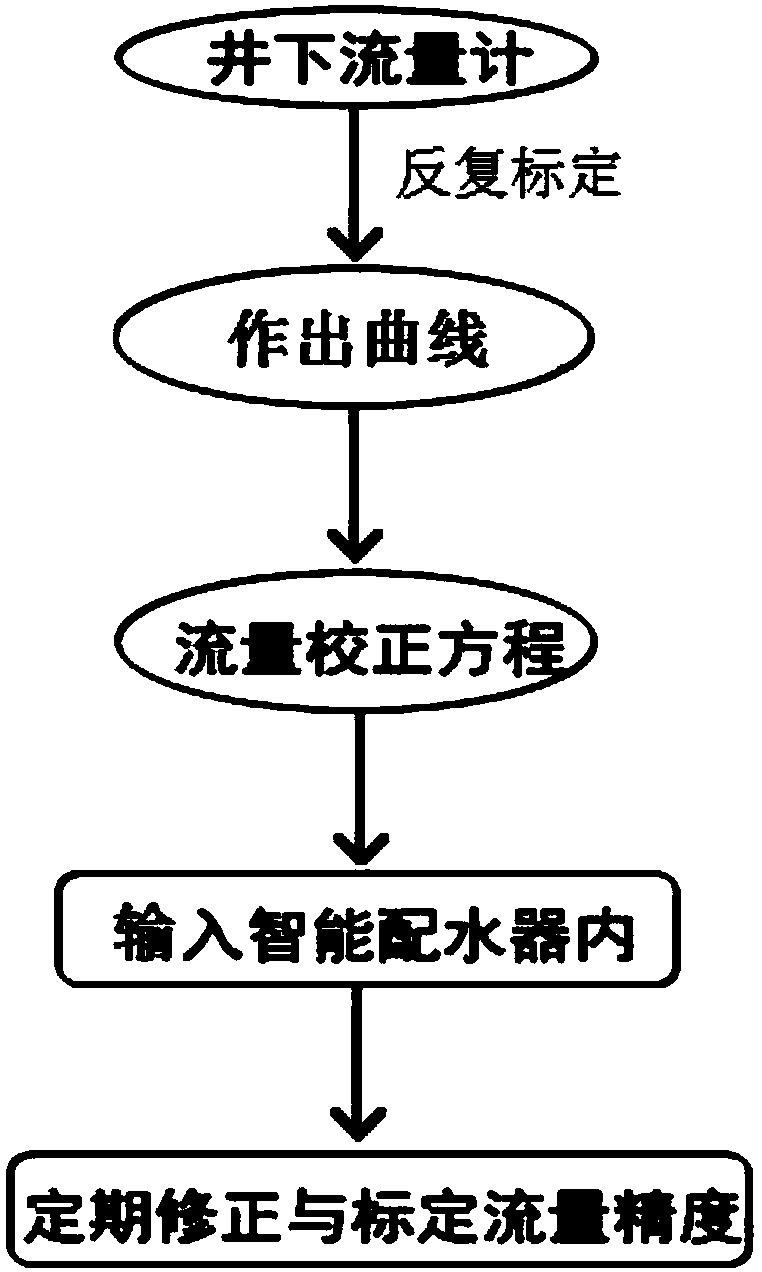

[0025] This embodiment provides a figure 1 The shown intelligent dispensing standard meter downhole flow calibration method includes the following steps:

[0026] Step 1, repeatedly calibrate the downhole flowmeter, and record the flow y and pressure x of the downhole flowmeter;

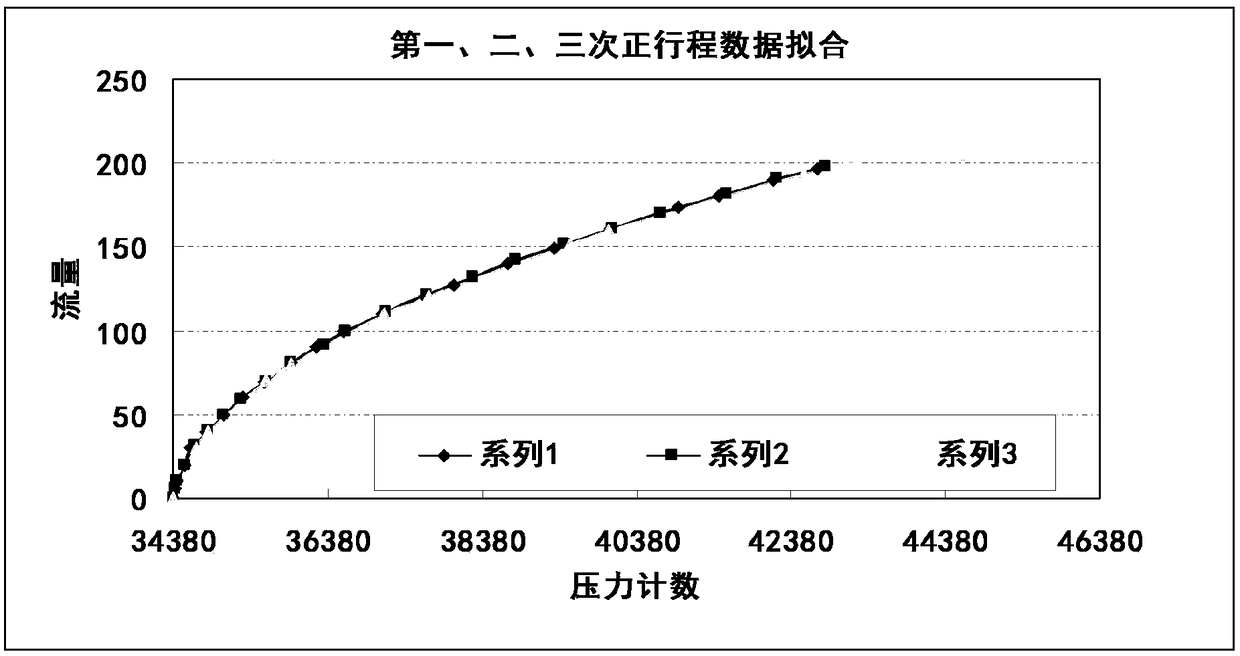

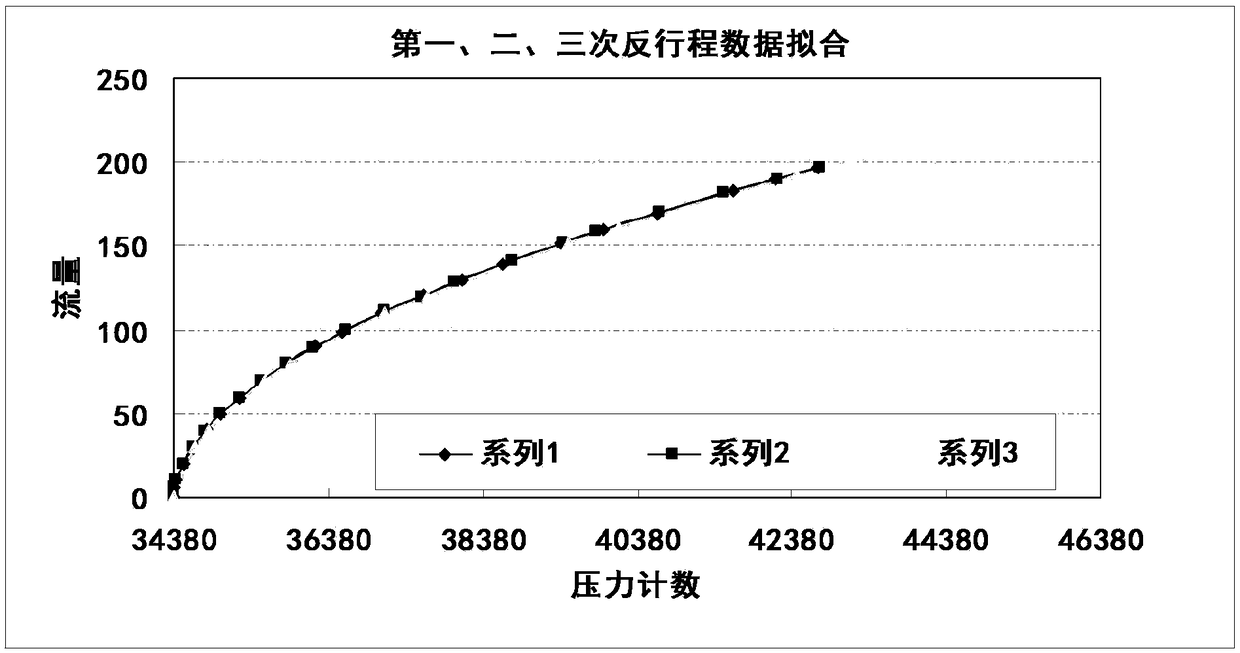

[0027] Step 2, taking the flow y and pressure x of the downhole flowmeter as the points on the Y-axis and the X-axis respectively, and drawing a curve;

[0028] Step 3, get the corresponding equation according to the curve obtained in step 2: y=21.253x 2 +285.33x-117.81;

[0029] Step 4, use the equation obtained in step 3 as the flow equation, use the flow y and pressure x in the flow equation as the flow and pressure of the water outlet of the smart water distributor, and input the flow equation into the smart water distributor, then the The intelligent water distributor is lowered into the well, and the intelligent water distributor automatically selects the appropriate flow rate to inject wate...

Embodiment 2

[0033] This embodiment provides a method for calibrating the downhole flow rate of an intelligent dispensing standard meter, which also includes the correction of the flow rate. After the intelligent water distributor is lowered into the well, an ultrasonic flowmeter is lowered into the well to measure the ratio every six months to one year. Yes, to ensure the normal execution of downhole flow calibration.

[0034] Further, put an ultrasonic flowmeter into the well, test the flow y1 and pressure x1 of the outlet of the intelligent water distributor, record them, and use the flow y1 and pressure x1 as points on the Y-axis and X-axis respectively to draw a new curve, A new equation is obtained according to the new curve, and when the new equation is different from the equation in step 3, input the new equation into the intelligent water distributor to continue working with a new signal.

[0035] The downhole flow calibration method of the intelligent dispensing standard meter of...

Embodiment 3

[0038] This embodiment provides a method for calibrating the downhole flow rate of an intelligent dispensing standard meter. The intelligent water distributor is provided with at least a flow unit, a communication unit, and a measurement and adjustment unit inside, and a controller is provided on the ground. The flow unit and The measuring and adjusting units are all electrically connected to the communication unit, and the communication unit is electrically connected to the controller.

[0039] The flow unit is integrated with a flow equation, and the intelligent water distributor injects water downhole according to the flow rate set by the flow equation. The measurement and adjustment unit is used to monitor the water injection volume and pressure of the intelligent water distributor in real time, and Adjust the water injection volume of the intelligent water distributor.

[0040] The flow unit and the measurement and adjustment unit transmit information to the communication...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com