Method for avoiding abnormal fractures of X90/X100 pipeline steel drop hammer sample

A technology of X90 and pipeline steel, which is applied in the direction of testing the strength of materials with a single impact force, to avoid abnormal fractures, increase the speed of crack propagation, and eliminate abnormal fractures.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

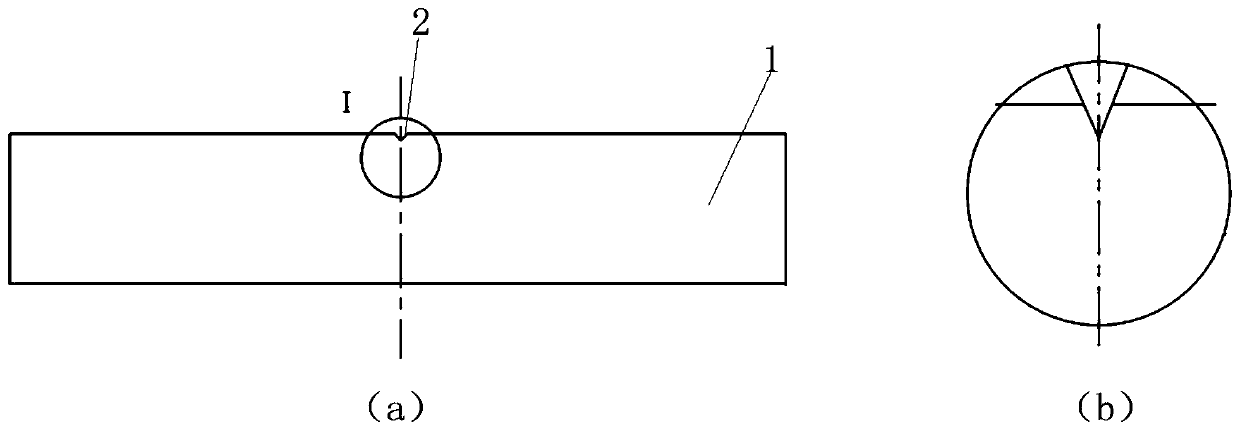

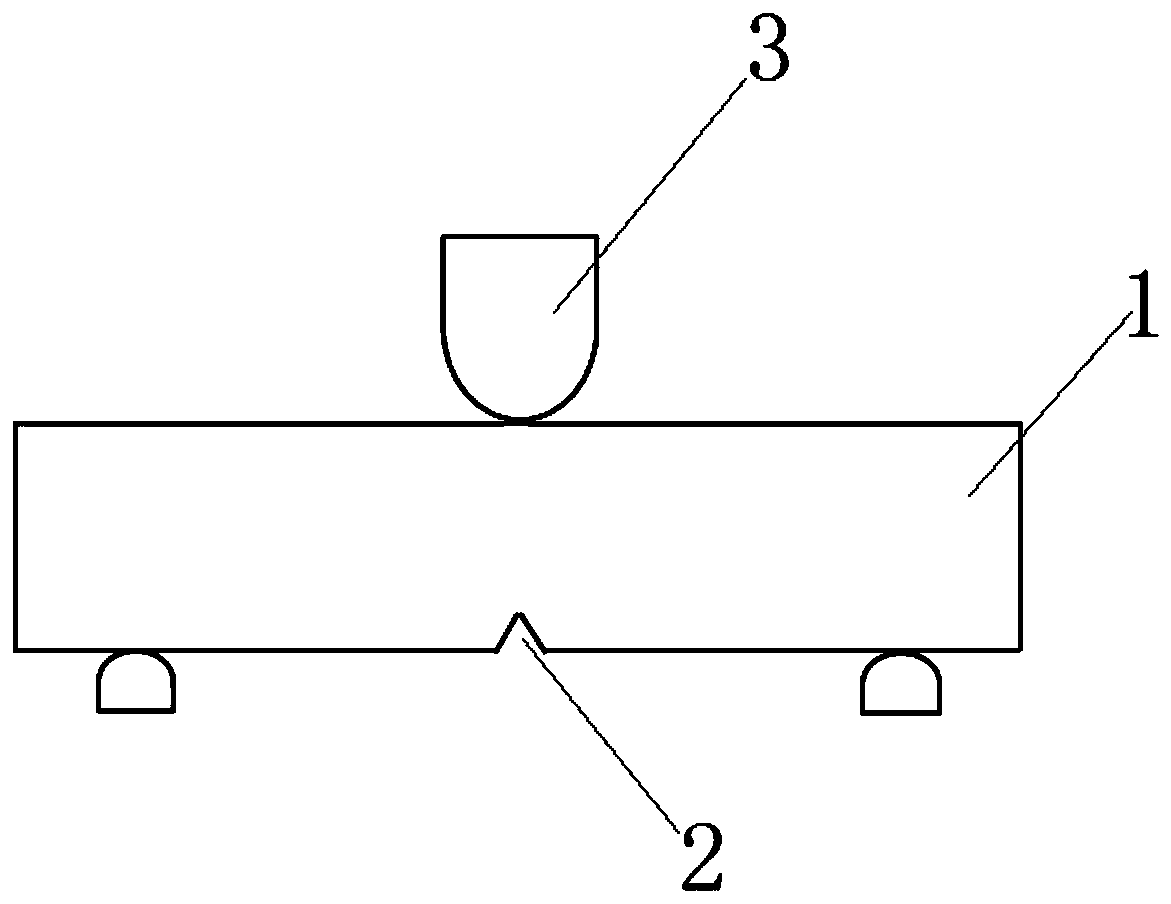

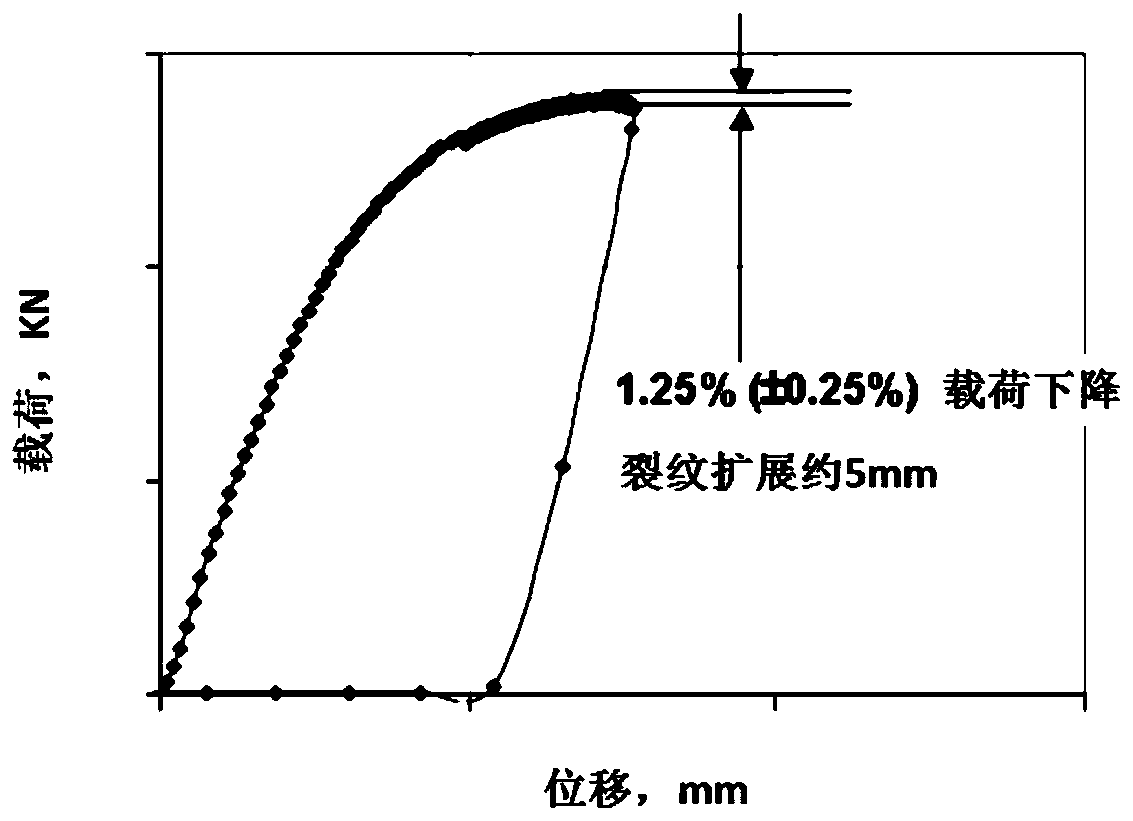

[0035] The invention provides a method for avoiding the abnormal fracture of the X90 / X100 pipeline steel drop weight sample. Firstly, the ordinary DWTT sample is processed according to the general standard, and then the initial crack is prefabricated at the root of the sample gap, and a back groove is added on the back of the sample. , increase the hammering energy during the DWTT test to ensure that the fracture morphology of the X90 / X100 steel pipe DWTT sample is a normal fracture.

[0036] The invention discloses a method for avoiding abnormal fractures of X90 / X100 pipeline steel drop hammer samples, comprising the following steps:

[0037] S1, DWTT sample processing

[0038] According to Q / SY GJX 101 "General Technical Conditions for Gas Transmission Steel Pipes", cut out the standard DWTT sample 1 (305mm in length, 76.2mm in width, and the wall thickness is the original wall thickness of the steel pipe), and press it with a special tool with a cutting edge angle of 45° T...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Edge angle | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com