Method and system for detecting surface defects of hose

A detection method and hose technology, which are used in optical testing flaws/defects, image data processing, instruments, etc., can solve the problems of poor detection stability, slow detection speed, and easy to form false detections, so as to improve detection speed and accuracy, The effect of improving the degree of production automation and improving the detection efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037] The technical solutions of the present invention will be further described below through specific embodiments in conjunction with the accompanying drawings.

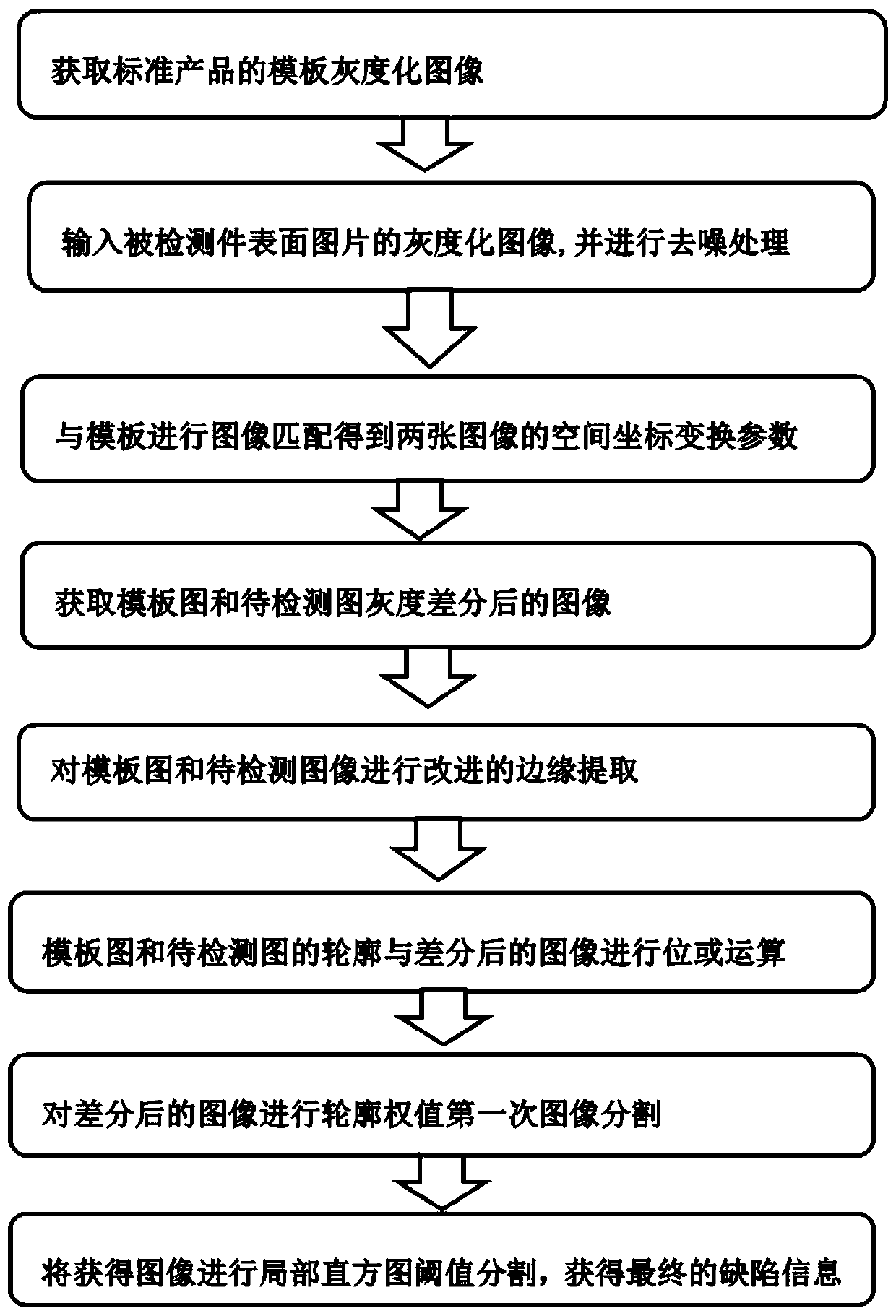

[0038] A method for detecting surface defects of a hose, comprising the following steps:

[0039] (1) Collect the standard hose image as the template image, and perform grayscale processing to obtain the image Back;

[0040] In step (1), the surface picture of the inspected piece is taken by the inspection camera, and the image is grayscaled to obtain a grayscale image of the surface picture of the inspected piece.

[0041] (2) gray-scale processing of the collected image of the hose to be detected, and use the NL-Means algorithm for denoising processing to obtain the image Fore;

[0042] (3) image Fore and image Back carry out image matching to obtain the spatial coordinate transformation parameters of the two images, and obtain new images Back_Pic and Fore_Pic after processing;

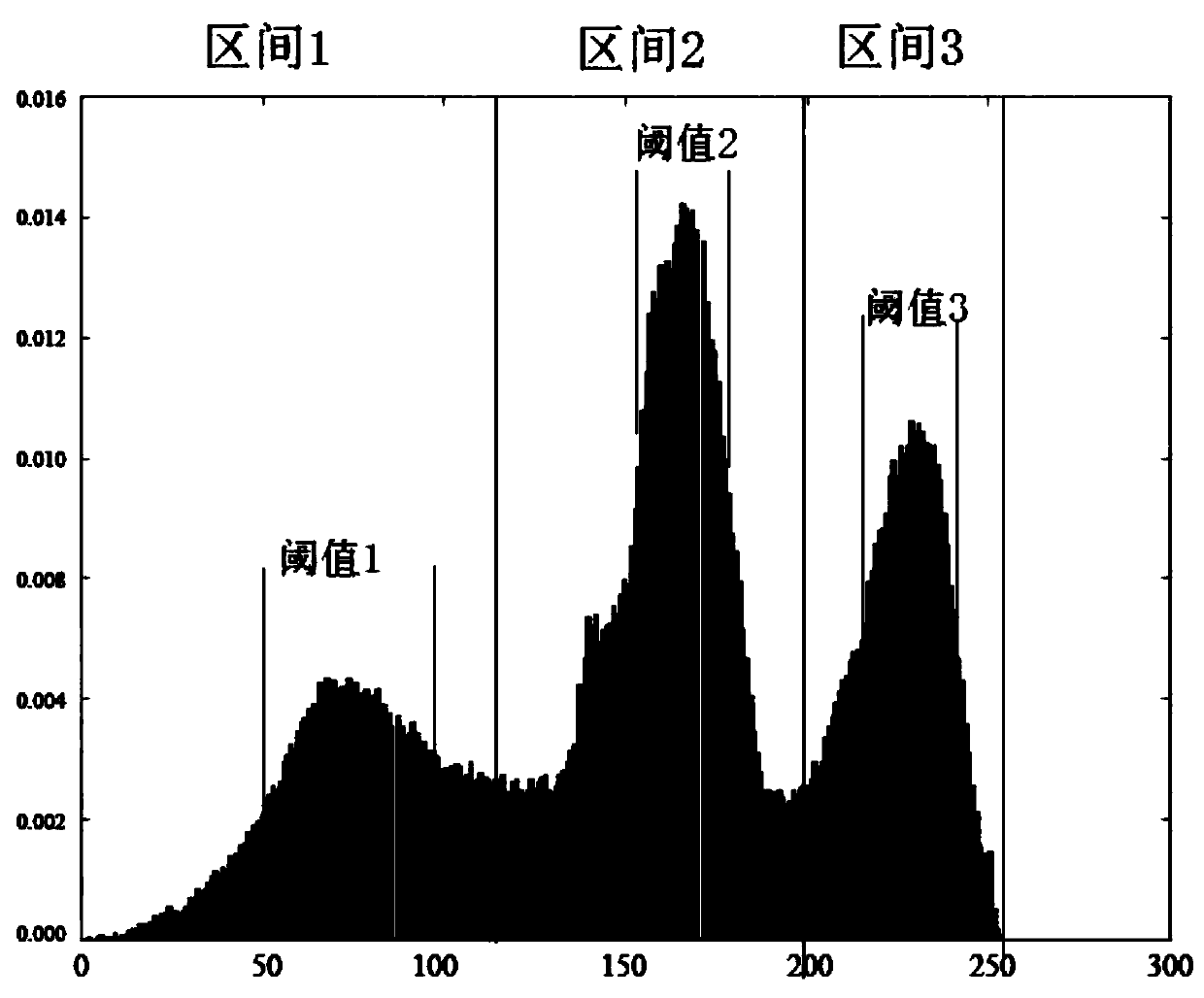

[0043] (4) Image difference pr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com