A klystron with a small integrated cooling structure

A technology of cooling structure and klystron, applied in klystrons, electron tubes with velocity/density modulation electron flow, time-of-flight electron tubes, etc., which can solve the problems of klystrons that are not easy to move, heavy in weight, and limited in application places To achieve the effect of ensuring one-way smooth circulation, avoiding excessive local temperature, and increasing the length of the process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

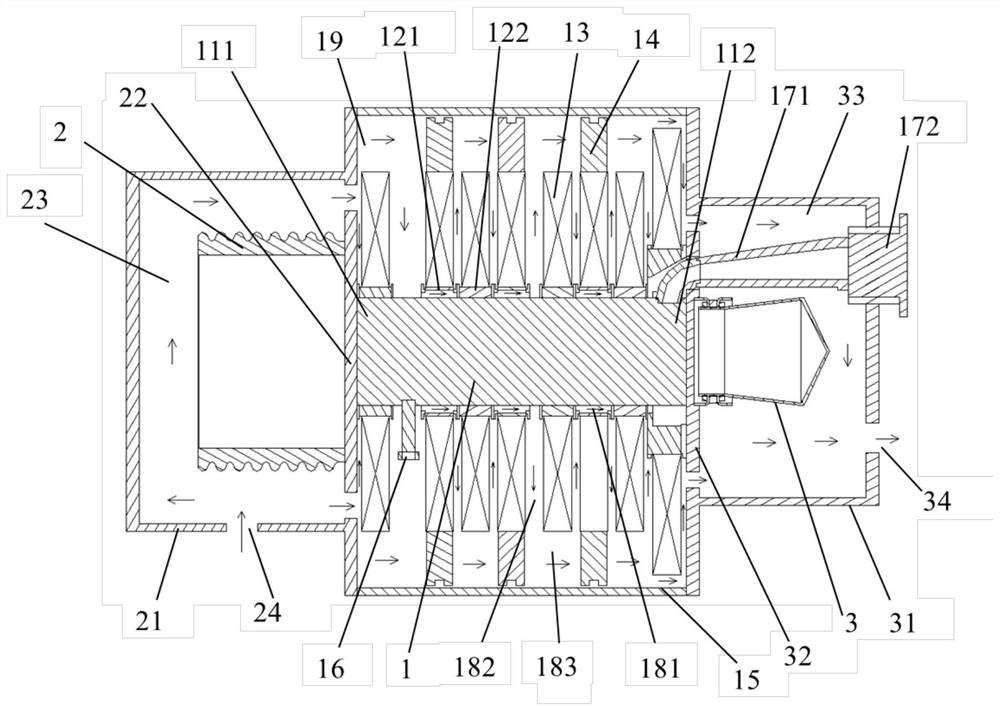

[0025] The present invention provides a klystron with a small integrated cooling structure, as shown in the accompanying drawings, including:

[0026] high frequency band 1;

[0027] The wire bag skeleton set on the outer periphery of the high frequency section 1, the wire bag skeleton includes a hollow wire bag skeleton 121 and a solid wire bag skeleton 122; a cooling liquid channel is formed between the inner wall of the hollow wire bag skeleton 121 and the outer wall of the high frequency section 1 , the inner wall of the solid wire bag skeleton 122 is closely attached to the outer wall of the high-frequency section 1; the hollow wire bag skeleton 121 and the solid wire bag skeleton 122 are arranged alternately;

[0028] The outer wall of the wire bag skeleton is combined and fixed with a wire bag 13, and the outer wall of the wire bag 13 fixed on the outer wall of the hollow wire bag skeleton 121 is sleeved with a coil sealing ring 14;

[0029] The coil sealing ring 14 is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com