Finishing and conveying mechanism with controllable process

A feeding mechanism and feeding technology are applied in the field of powder metallurgy and powder metallurgy finishing equipment, which can solve the problems of mold damage and feeding mechanism damage, and achieve the effects of reliable performance, high work efficiency and high safety.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

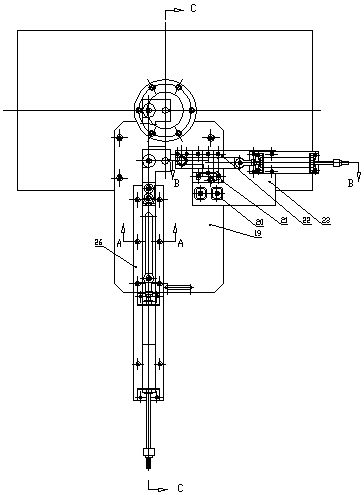

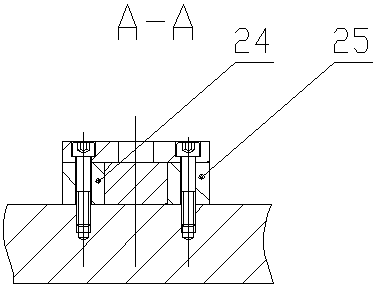

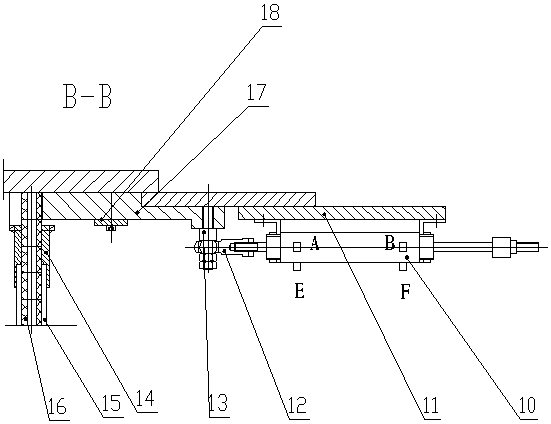

[0022] The invention adopts a finishing feeding device whose feeding process can be detected. The powder metallurgy products are automatically loaded into the feeding conduit through the vibrating plate, and enter the fixing seat of the feeding conduit from the discharging conduit, and are pushed into the feeding clamp through the pushing mechanism equipped with process control fixed on the machine tool, and the feeding clamp is clamped The finished product is sent to the shaping die under the action of the feeding mechanism equipped with process control fixed on the machine tool, and then the feeding mechanism returns the feeding clamp to the pushing position. The upper and lower die punches installed on the machine tool press the product into the female mold installed on the machine tool for shaping. After shaping, the product is pushed out by the upper die punch installed on the machine tool under the action of the machine tool. In the next step During circulation, when the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com