A high-purity gas cylinder grinding process

A production process and high-purity technology, which is applied in the direction of grinding machine tools, manufacturing tools, grinding devices, etc., can solve the problems of inability to fill high-purity gas and low grinding efficiency, and achieve the effect of protecting cleanliness and preventing secondary pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

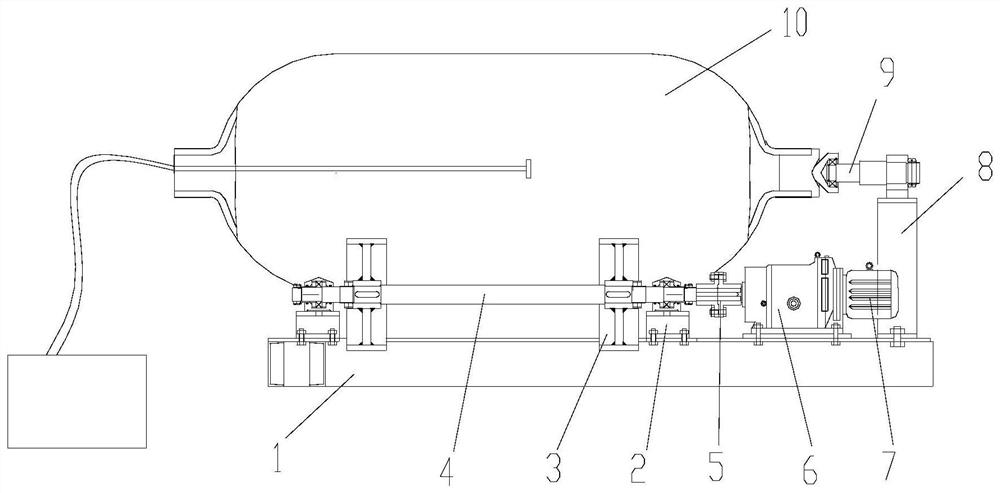

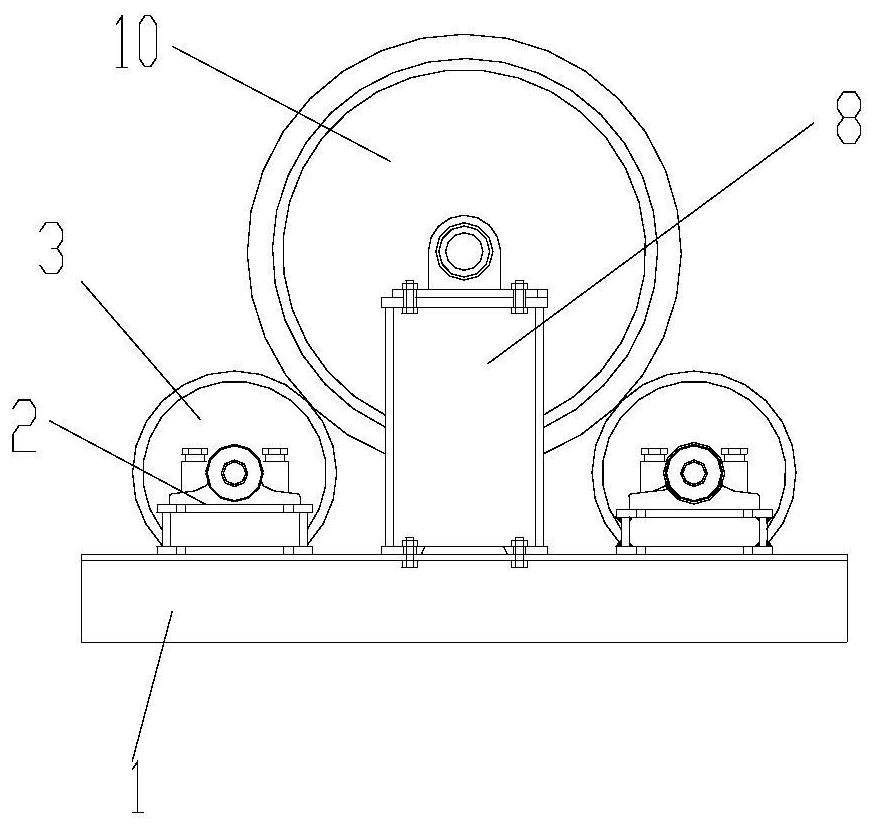

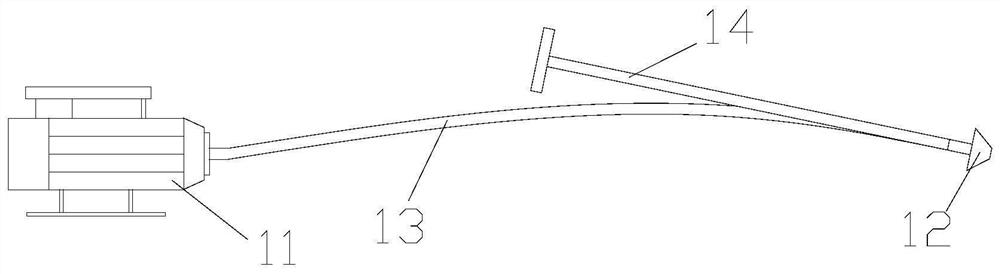

Method used

Image

Examples

Embodiment 2

[0048] This embodiment is the same as Embodiment 1, except that step 1 is omitted.

[0049] In this embodiment, the time for the inner wall roughness to reach 0.3 μm after fine grinding is 30 hours.

Embodiment 3

[0051] This embodiment is the same as that of Embodiment 1, except that the qualified standard for the smoothness of the inner wall in step 1 is 14 μm.

[0052] In this embodiment, the time for the inner wall roughness to reach 0.3 μm after fine grinding is 15 hours.

Embodiment 4

[0054] This embodiment is the same as that of Embodiment 1, except that the qualified standard for the smoothness of the inner wall in step 1 is 16 μm.

[0055] In this embodiment, the time for the inner wall roughness to reach 0.3 μm after fine grinding is 10 hours.

PUM

| Property | Measurement | Unit |

|---|---|---|

| surface roughness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com