Isolated environment-friendly garbage reciprocating briquetting machine

A briquetting machine, an environmentally friendly technology, applied in the direction of presses, manufacturing tools, etc., can solve the problems of isolation treatment, odor overflow, sewage and odor, etc., achieve the best isolation effect and avoid the effect of blocking

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

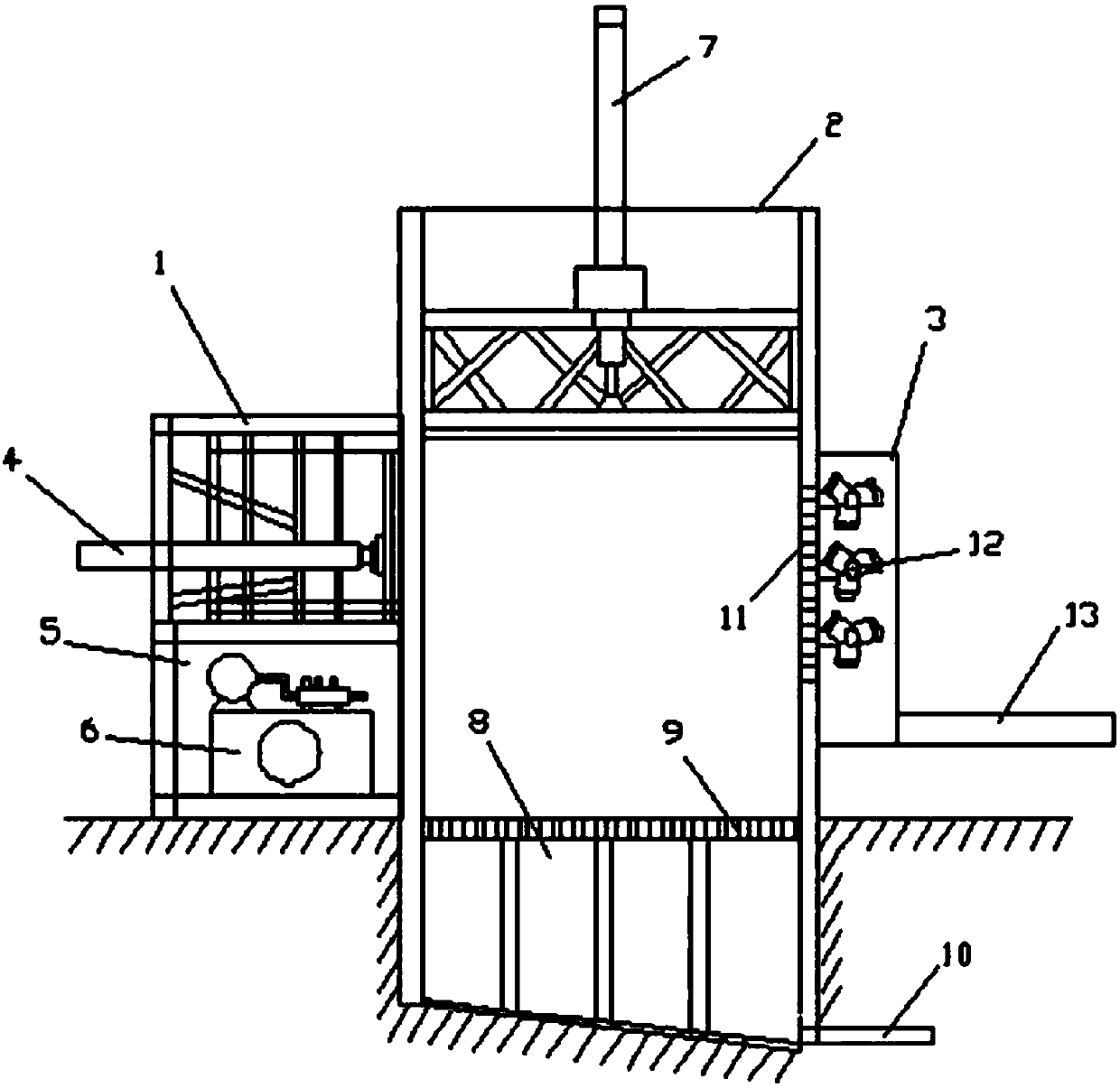

[0010] refer to figure 1 As shown, an isolated environment-friendly garbage reciprocating briquetting machine includes a feeding device 1, a body 2 and an energy releaser 3, the feeding device 1 is located on one side of the body 2, and the energy releaser 3 is located on the other side of the body 1 Side, the feeding device 1 includes a connecting shaft 4 and an integral base 5, the integral base 5 is provided with a driving device 6, the connecting shaft 4 is electrically connected to the driving device 6, and the driving device 6 is provided with a corresponding The control panel (not shown in the figure) can control the rotation of the coupling shaft 4, and pour the garbage into the body 2. After the garbage is poured, the coupling shaft 4 rotates in a vertical state, which can just form a closed structure inside the body 2 , after the briquetting is completed, the connecting shaft 4 is rotated again to become a horizontal state, so as to repeat the operation. The body 2 i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com