Carbon fiber automobile hub and manufacturing method thereof

A technology of automobile hub and carbon fiber, which is applied in the direction of wheels, spoked wheels, rims, etc., can solve the problems of long production time, influence of automobile fuel consumption and acceleration ability, low production efficiency, etc., and achieve improved driving comfort and good shock absorption effect , the effect of improving production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0049] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

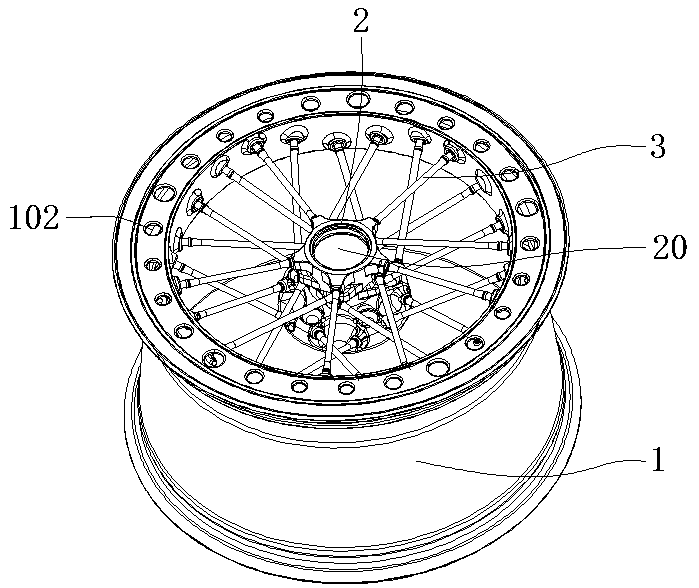

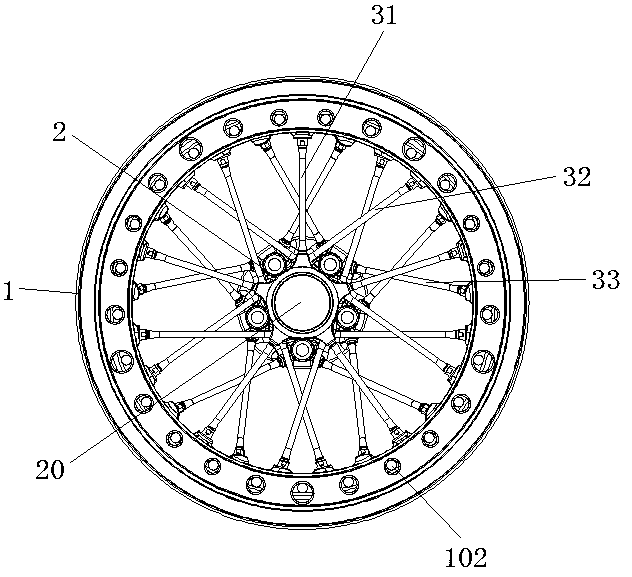

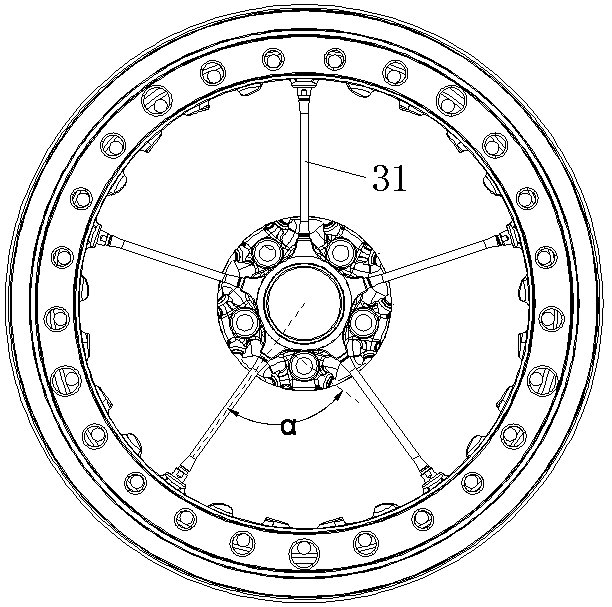

[0050] Such as Figure 1-13As shown, a carbon fiber automobile hub includes a rim 1, a hub 2 and several spokes 3, the rim 1 is a carbon fiber rim, the hub 2 can be made of metal, preferably aluminum alloy, and the center of the hub 2 is provided with a 1 coaxial axle mounting holes 20. The outer surface of the wheel hub 2 is provided with several first spoke installation holes 21 along the circumferential direction, and the inner surface of the rim 1 is provided with several second spoke installation holes 101 along the circumferential direction. Nut 4 for spoke 3. The two ends of the spoke 3 are respectively provided with external threads, the first spoke mounting hole 21 is provided with internal threads, one end of the spoke 3 is fixedly installed in the first spoke mounting hole 21, and the other end extends into the second spoke mountin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com