Inflatable bionic wing and processing method thereof

A processing method and inflatable technology, which can be used in aircraft assembly, helicopters, aircraft, etc., can solve the problems of poor folding and large wings, and achieve the effects of easy storage, compact volume and novel structure.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

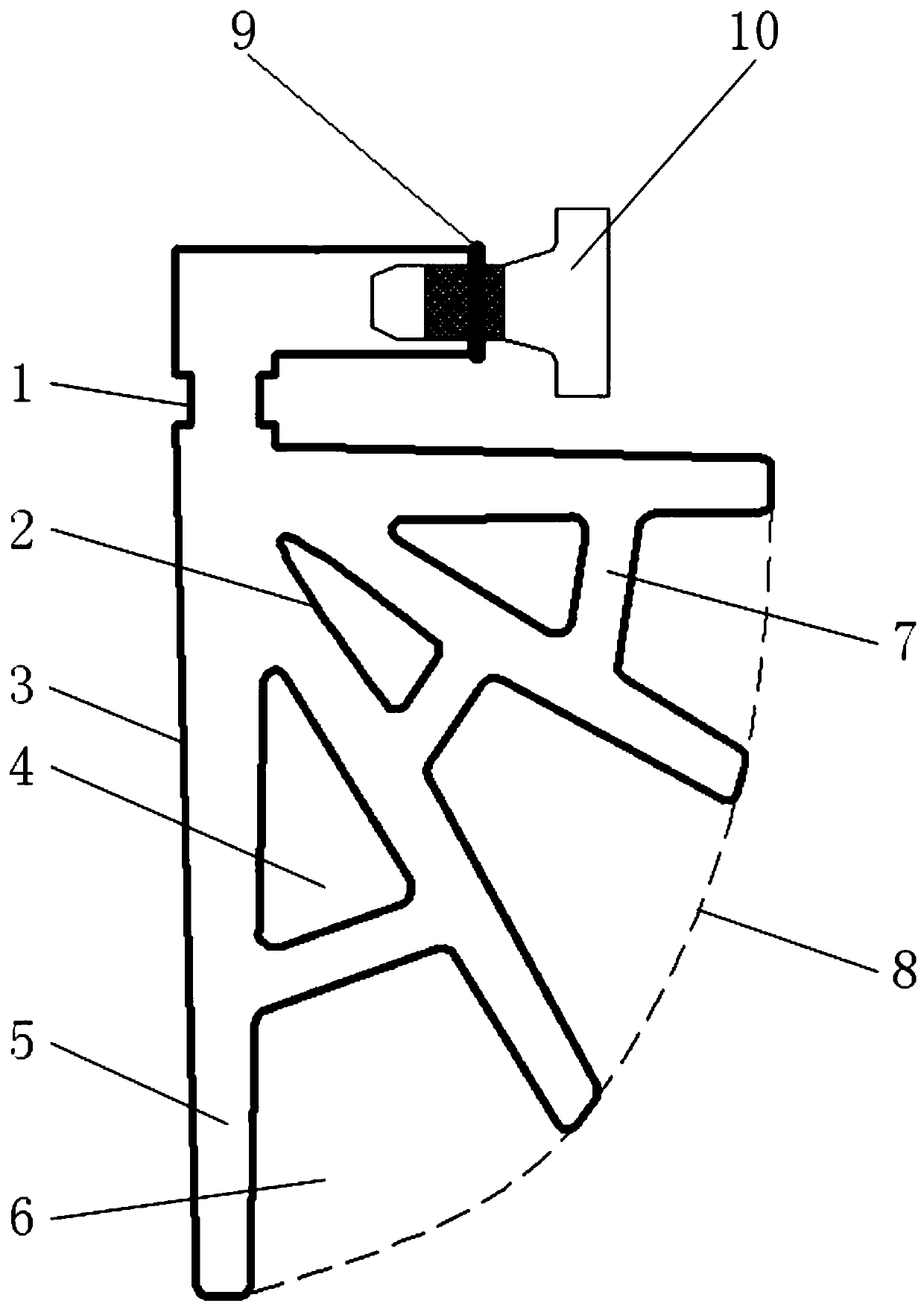

[0026] Such as figure 1 As shown, the upper and lower two layers of plastic film 24 form a hollow structure through the inner heat sealing line 2 and the outer heat sealing line 3, including the main vein wing column 5 and the interlaced wing column 7, wherein the main wing vein wing column 5 adopts a cone Shaped structure, near the root end of the wing adopts a large-diameter structure, and the root end of the far wing adopts a small-diameter structure, and the staggered vein wing column 7 adopts a columnar structure for connecting two main wing vein wing columns 5, and the inner wing surface 4 is formed by The inner heat sealing line 2 is closed and formed, the outer airfoil 6 is formed by the outer heat sealing line 3 and the cutting track 8, and the clamping wing column 1 is located at the root of the main wing vein wing column 5, and its diameter is smaller than the root diameter of the main wing vein wing column. It is used to be installed on the actuator of the flapping...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com