A cardboard packaging line

A packaging line and cardboard technology, which is applied in packaging, transportation packaging, packaging protection, etc., can solve the problems of unqualified packaging, high production costs of enterprises, and unsmooth adhesion of tapes, etc., and achieve the effect of stable cardboard packaging and tape adhesion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

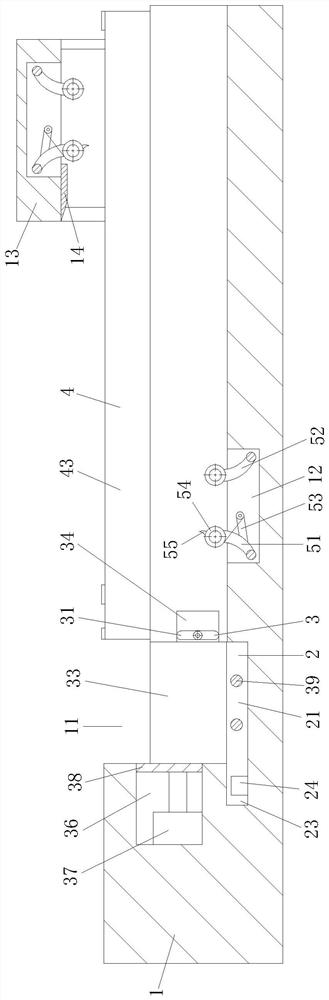

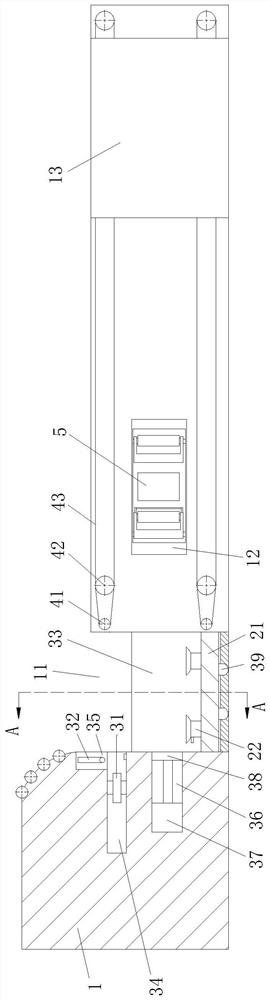

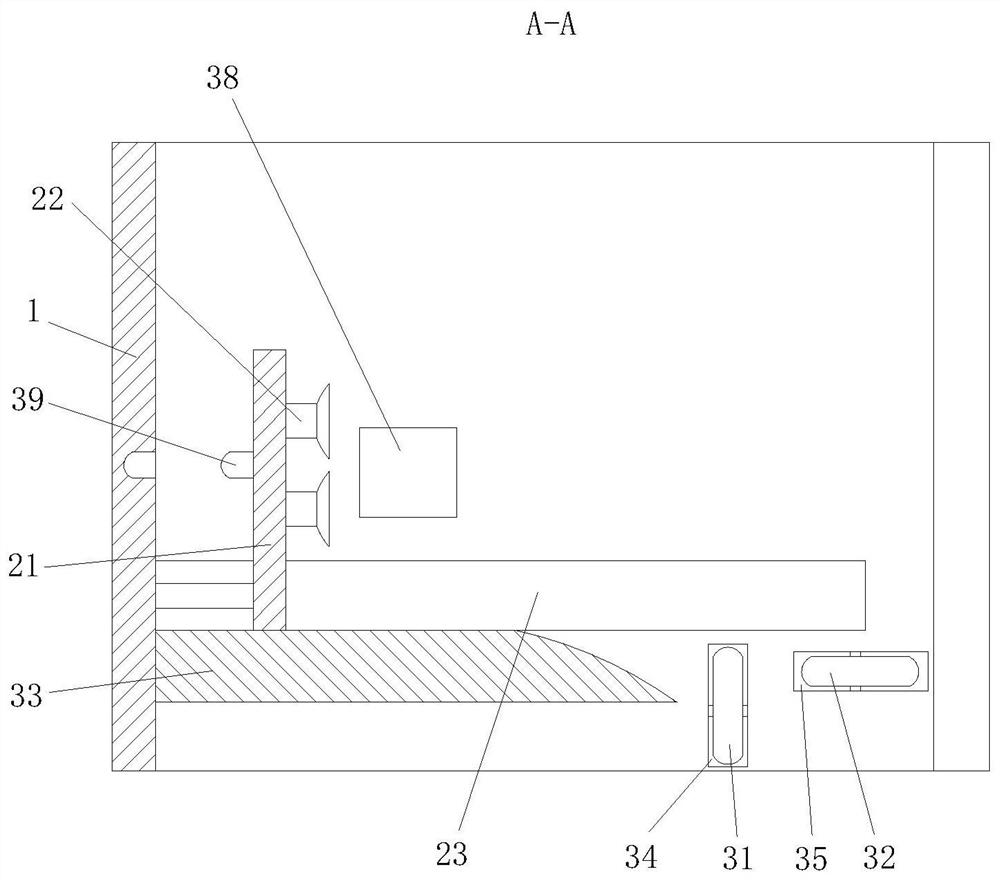

[0025] As an embodiment of the present invention, the frame 1 is in an "L" shape as a whole, and the surface of the frame 1 is provided with a first groove 11; the suction unit 2 is located in the first groove 11; the suction The unit 2 includes a moving plate 21 and a suction cup 22; a first chute 23 is provided on the side wall of the first groove 11; a first cylinder 24 is fixedly connected in the first chute 23; The cross section is "T" shape design, and one end of the moving plate 21 slides in the first chute 23, and the protruding end of the first cylinder 24 is fixedly connected to the end of the moving plate 21 sliding in the first chute 23, the first The cylinder 24 is electrically connected with the controller, supplied with air from an external air source, to realize the forward and backward movement of the moving plate 21; the side of the moving plate 21 away from the frame 1 is fixedly connected with suction cups 22 arranged uniformly; the suction cups 22 and When...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com