A thermoformed product rack for the production of cemented carbide

A cemented carbide, thermoforming technology, applied in the external frame, packaging, container handles, etc., can solve the problems of affecting the blank forming efficiency, weak blank protection effect, slowing down the forming efficiency, etc., to speed up the heating efficiency and heat The effect of uniformity, large loading, and improving molding efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

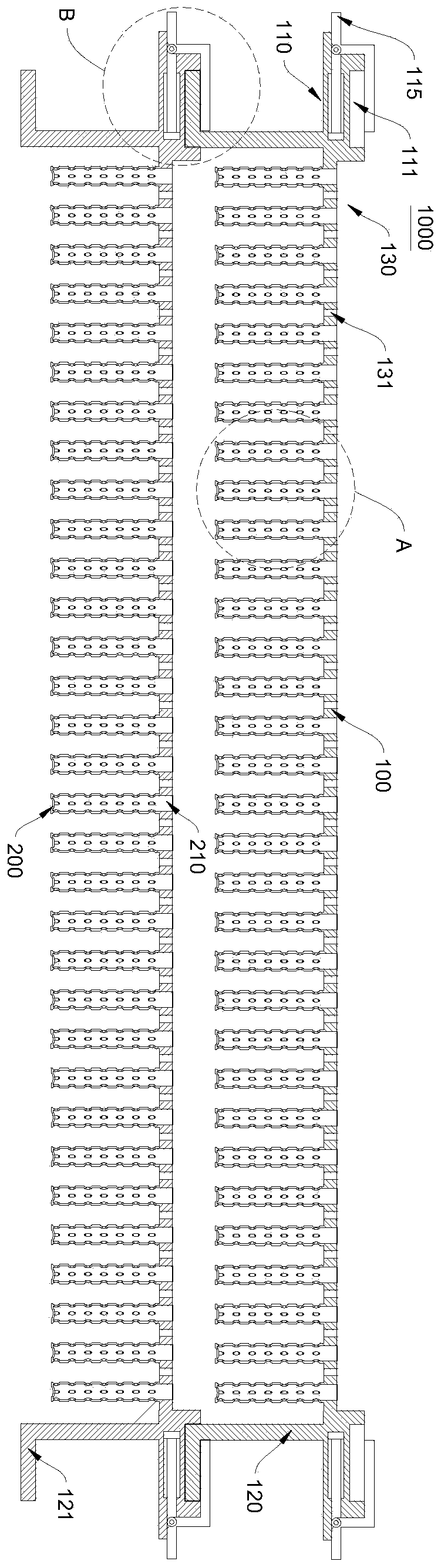

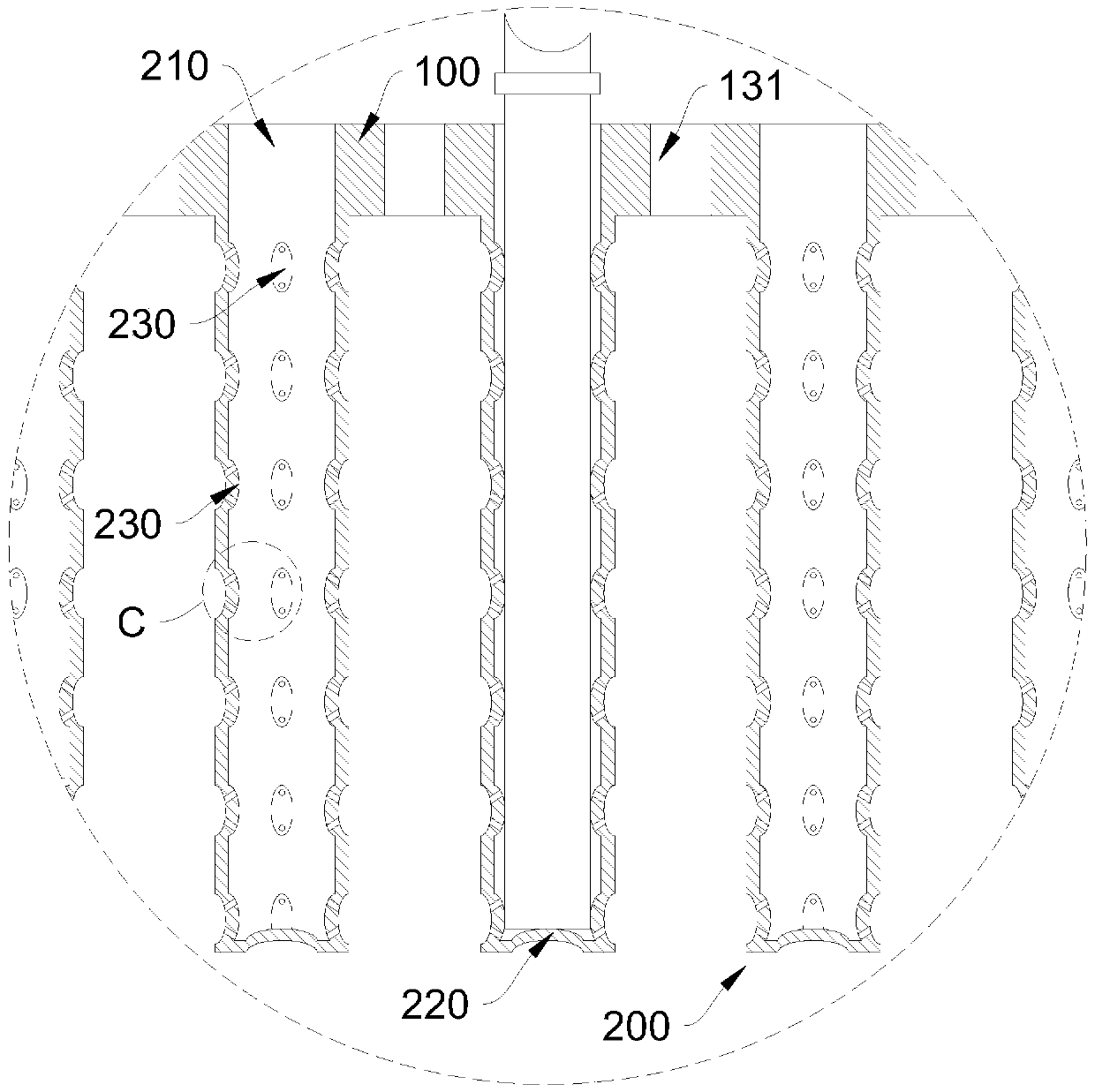

[0040] Please refer to Figure 1~4 , this embodiment provides a hot-formed product rack 1000 for producing cemented carbide. The thermoformed product rack 1000 includes: a plate body 100 and an accommodating cylinder 200 .

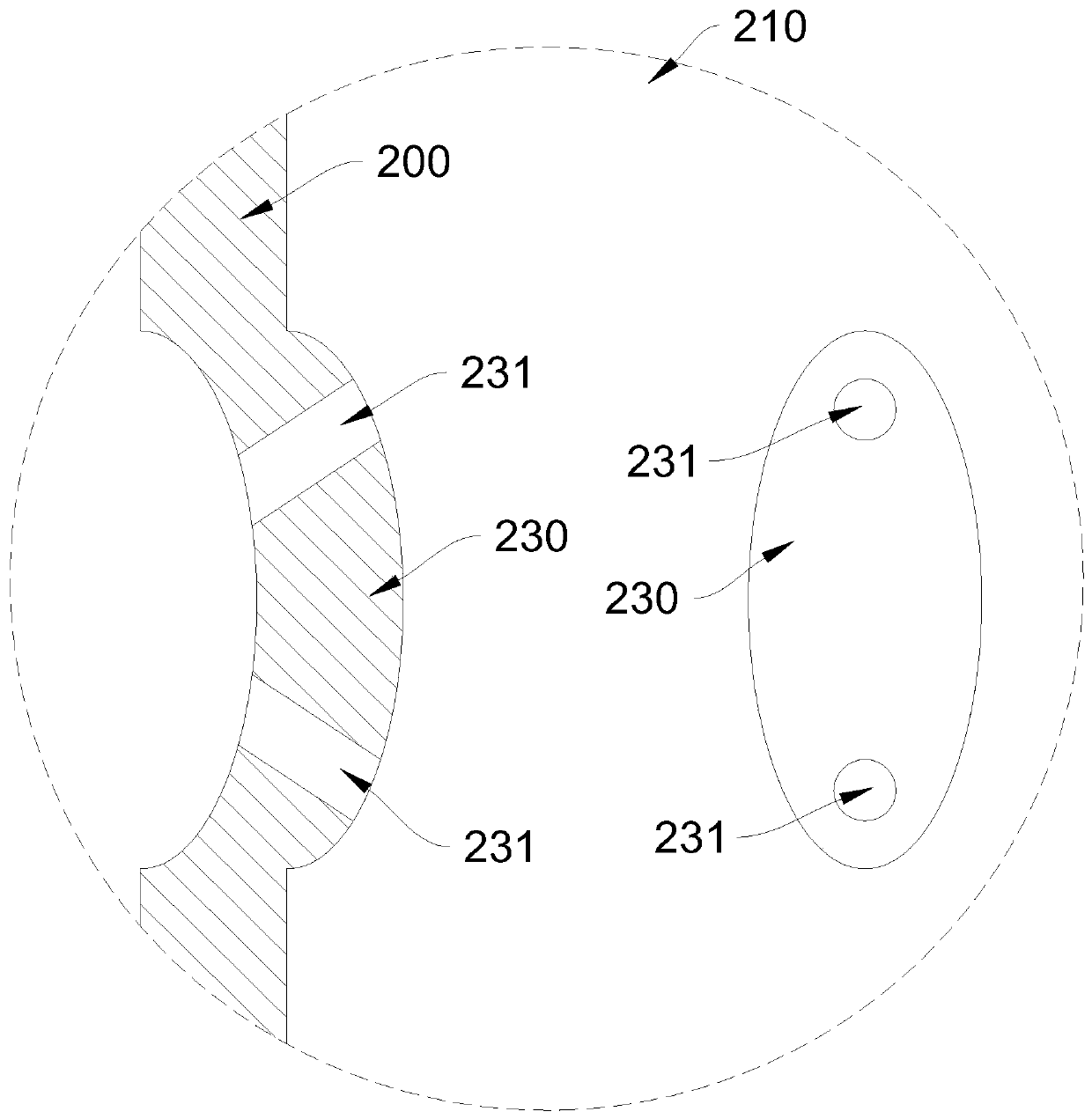

[0041] The accommodating cylinders 200 are arranged perpendicular to the surface of the board body 100 and embedded in the board body 100 , and the accommodating cylinders 200 are distributed in an array along the surface of the board body 100 . The accommodating cylinder 200 has an accommodating cavity 210 for placing a turning tool or a milling cutter, the bottom wall of the accommodating cylinder 200 has a first bulge 220 formed by indenting from the outside to the inside, and the side wall of the accommodating cylinder 200 has a The second protruding portion 230 is recessed inwardly. Along the circumferential direction and the axial direction of the housing cylinder 200 , the second protruding portions 230 are evenly spaced. The second protruding po...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com