Method and system for preparing phenylpropionic acid

A preparation system, the technology of phenylpropionic acid, applied in the field of phenylpropionic acid preparation, can solve the problems of lower production efficiency, cumbersome operation, large environmental interference, etc., and achieve the effect of flexible use, convenient operation and high preparation stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

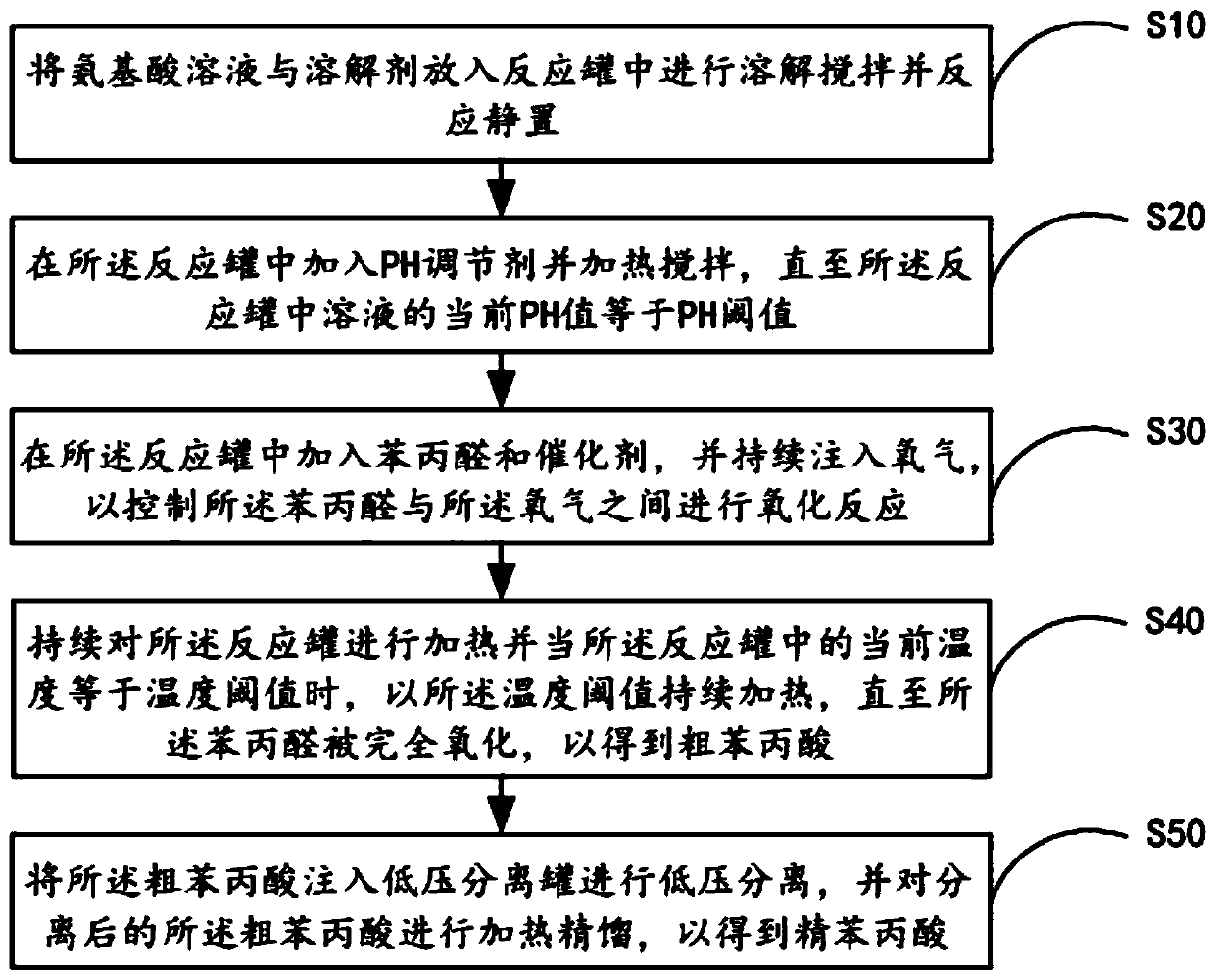

[0034] see figure 1 , a flow chart of the steps for the preparation method of phenylpropionic acid provided in the first embodiment of the present invention, including steps:

[0035] Step S10, putting the amino acid solution and dissolving agent into a reaction tank for dissolving and stirring, and reacting and standing still;

[0036] Wherein, the standing time for the reaction to stand still is 1 hour, the dissolving agent is distilled water, the reaction tank is made of an elliptical structure made of stainless steel, and the reaction tank is provided with a plurality of feeding ports. An end cover is provided on the feed port, and the amino acid solution and the dissolving agent are fed through the corresponding feed port. Preferably, a stirring motor is provided on the side wall of the reaction tank, and the stirring of the stirring motor The shaft runs through the reaction tank, and the end of the stirring shaft is provided with a stirrer, which is used to stir the ami...

Embodiment 2

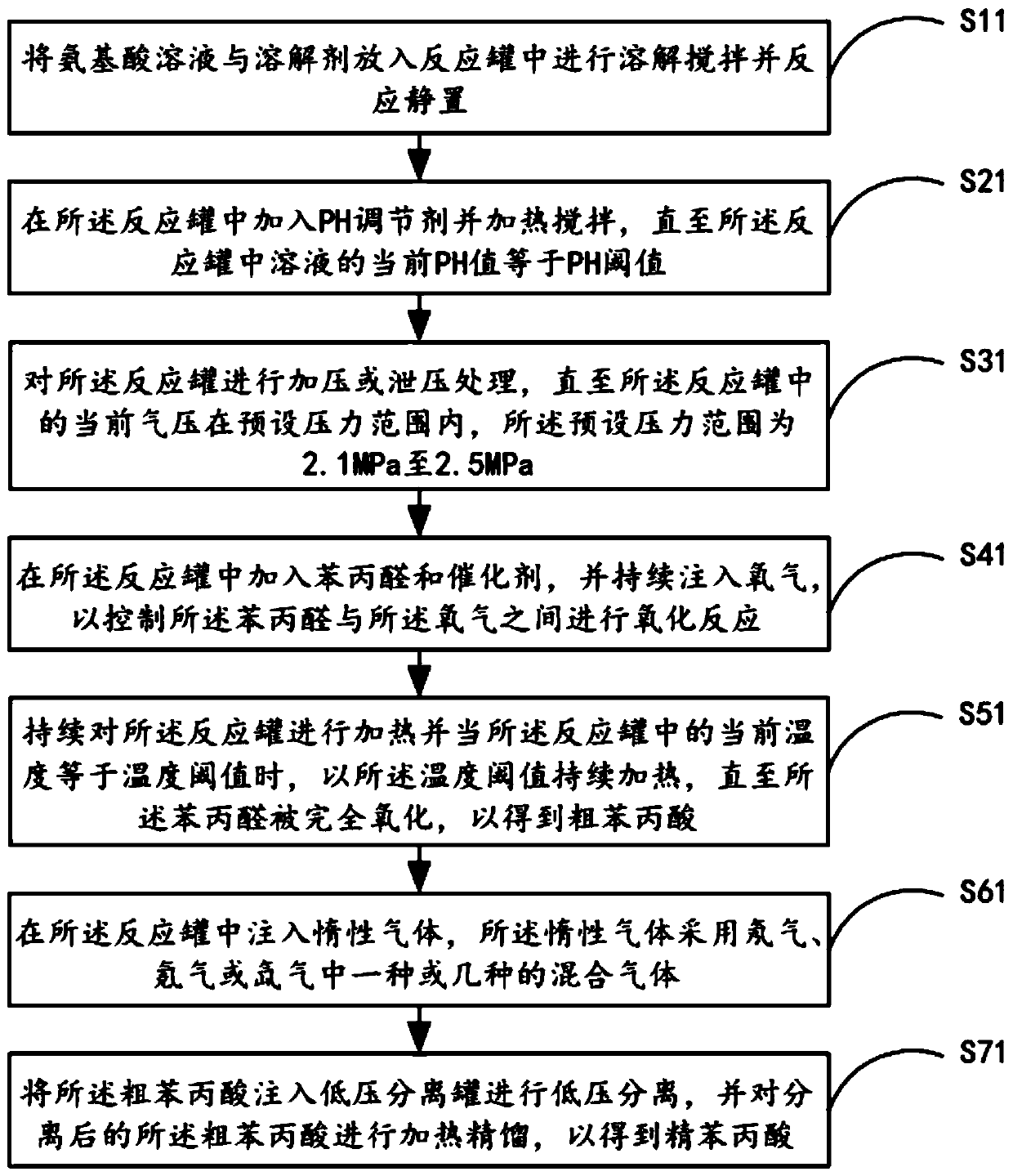

[0047] see figure 2 , a flow chart of the steps for the preparation method of phenylpropionic acid provided in the second embodiment of the present invention, including steps:

[0048] Step S11, putting the amino acid solution and dissolving agent into the reaction tank for dissolving and stirring, and reacting and standing still;

[0049]Wherein, the standing time for the reaction to stand still is 1 hour, the dissolving agent is distilled water, the reaction tank is made of an elliptical structure made of stainless steel, and the reaction tank is provided with a plurality of feeding ports. An end cover is provided on the feed port, and the amino acid solution and the dissolving agent are fed through the corresponding feed port. Preferably, a stirring motor is provided on the side wall of the reaction tank, and the stirring of the stirring motor The shaft runs through the reaction tank, and the end of the stirring shaft is provided with a stirrer, which is used to stir the ...

Embodiment 3

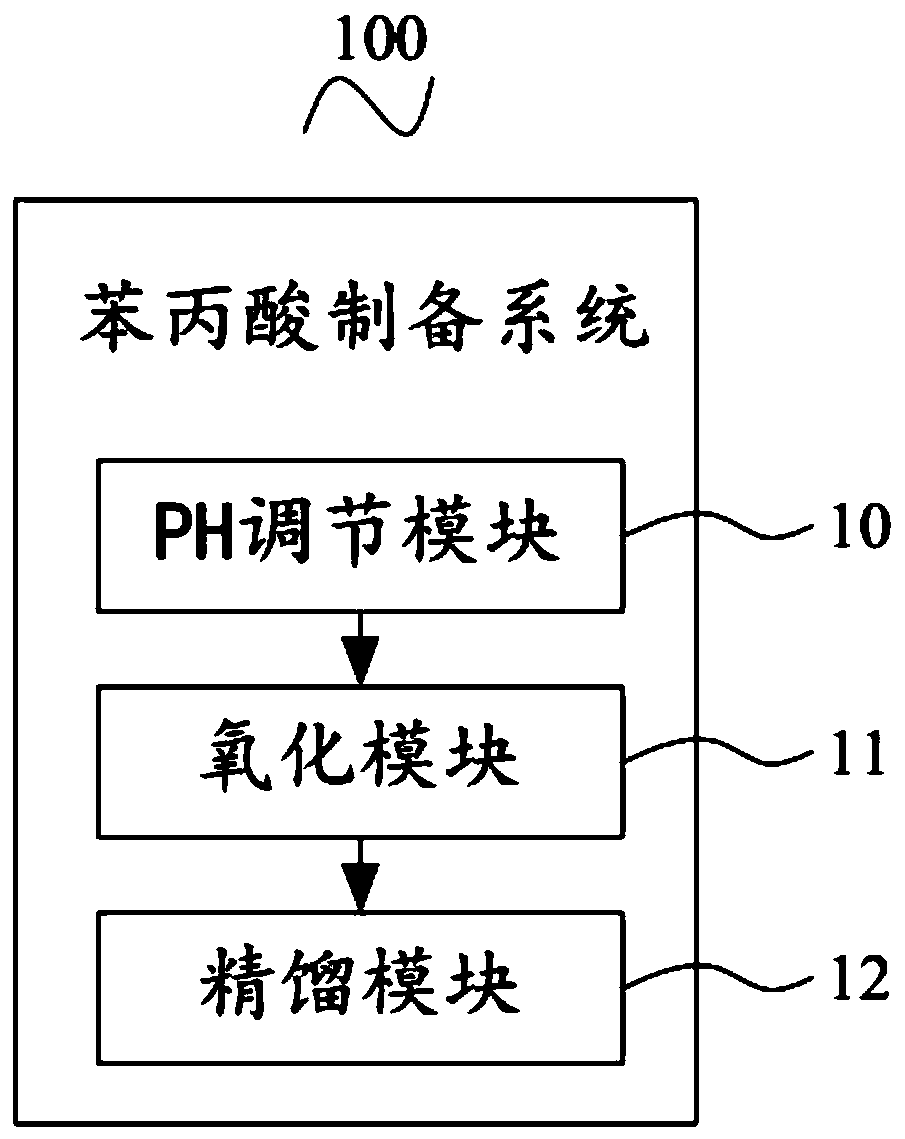

[0062] see image 3 , is a schematic structural diagram of the phenylpropionic acid preparation system 100 provided in the third embodiment of the present invention, including:

[0063] The PH adjustment module 10 is used to put the amino acid solution and the dissolving agent into the reaction tank for dissolving and stirring and reacting and standing still, add the pH adjusting agent in the reaction tank and heat and stir until the current pH of the solution in the reaction tank value is equal to the pH threshold, wherein, the standing time of the reaction is 1 hour, the dissolving agent is distilled water, and the reaction tank is made of an elliptical structure made of stainless steel, and the reaction tank is provided with a plurality of Feed port, the feed port is provided with an end cover, and the amino acid solution and the dissolving agent are fed through the corresponding feed port. Preferably, a stirring motor is provided on the side wall of the reaction tank, so ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com