Balanced vulcanization system for resisting high-temperature vulcanization reversion of natural rubber

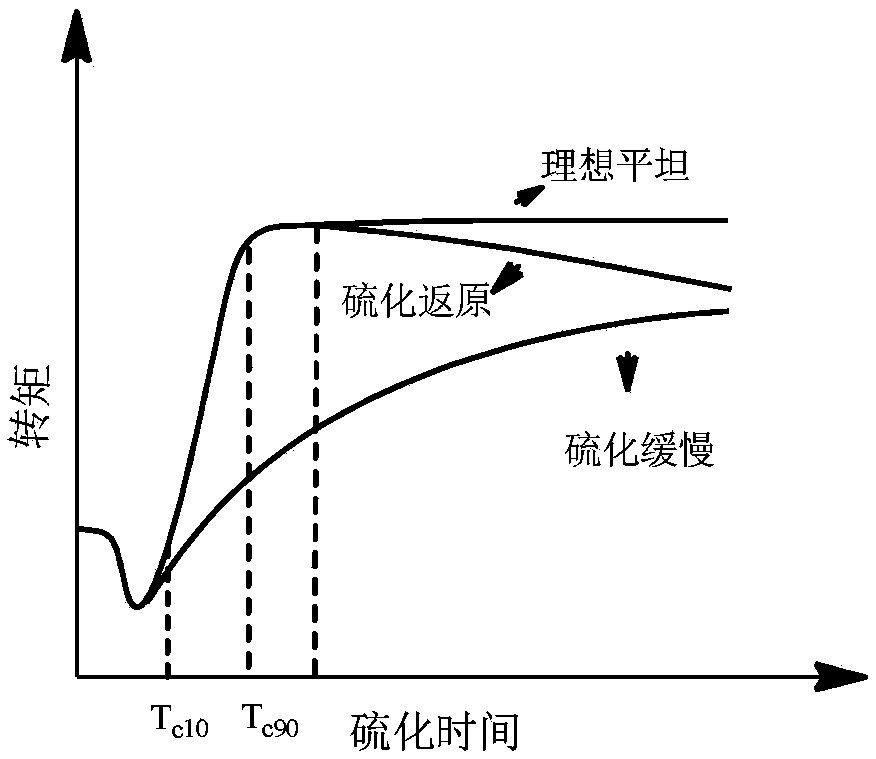

A vulcanization system and vulcanization reversion technology, applied in the field of new balanced vulcanization system, can solve the problems of vulcanization speed influence, vulcanized rubber performance, easy reversion, etc., to achieve the effect of realizing production efficiency and shortening vulcanization time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

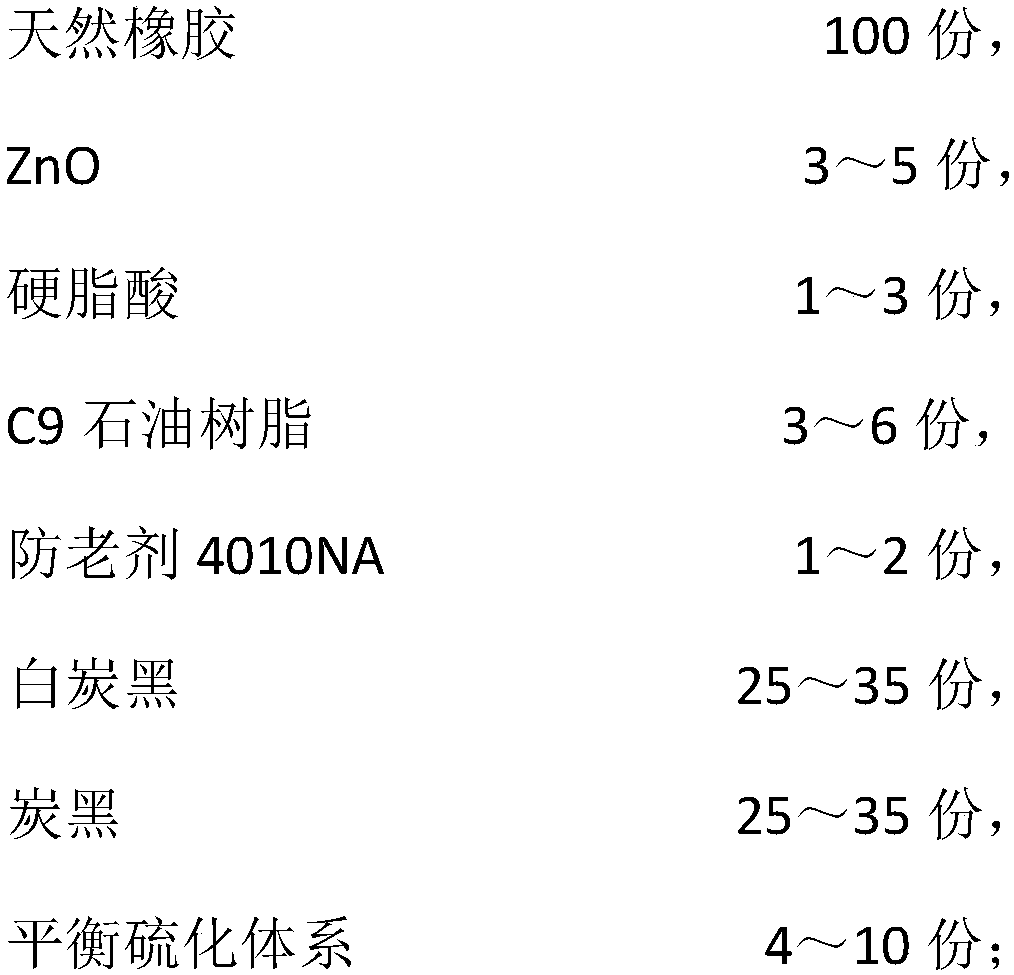

[0021] A balanced vulcanization system formulation for natural rubber resistant to high-temperature vulcanization reversion, consisting of the following raw materials in parts by mass:

[0022]

[0023] The equilibrium vulcanization system is composed of N, N-dithiodicaprolactam, sulfur, and benzothiazole disulfide, with a mass ratio of 1:0.5:1.

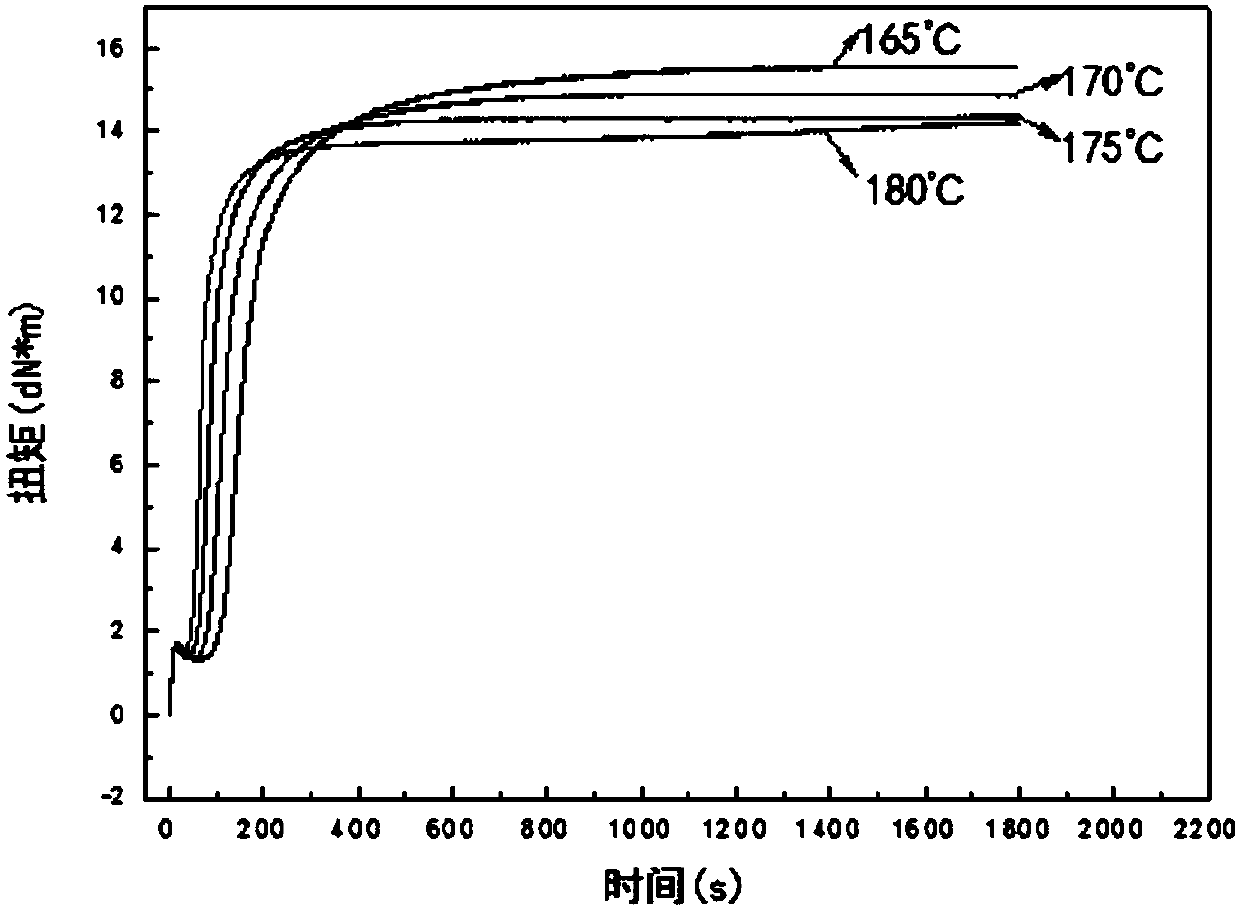

[0024] Thin-pass plasticizing of natural rubber on the open mill, control the temperature of the rollers below 30°C, cool and park for 12-24 hours after feeding; wrap the plasticized natural rubber on the rollers of the open mill according to the formula, press Add various additives sequentially in the order of feeding, fully mix evenly and then release the sheet. During the mixing process, control the roller temperature below 50°C; test the vulcanization characteristic curve after cooling and parking for 12 hours, and vulcanize the standard test sample on a flat vulcanizing machine according to the vulcanization conditions (artic...

Embodiment 2

[0034] A balanced vulcanization system formulation for natural rubber resistant to high-temperature vulcanization reversion, consisting of the following raw materials in parts by mass:

[0035]

[0036] The equilibrium vulcanization system is composed of N, N-dithiodicaprolactam, sulfur, and benzothiazole disulfide, with a mass ratio of 1:1:1.5.

[0037] Put the natural rubber on the open mill for thin pass plasticizing, control the temperature of the rollers below 40°C, cool and park for 12-24 hours after feeding; wrap the plasticized natural rubber on the rollers of the open mill according to the formula, press Add various additives sequentially in the order of feeding, fully mix evenly, and then release the sheet. During the mixing process, control the roller temperature below 60°C; test the vulcanization characteristic curve after cooling and parking for 12 hours, and vulcanize the standard test sample on a flat vulcanizer according to the vulcanization conditions. (art...

Embodiment 3

[0047] A balanced vulcanization system formulation for natural rubber resistant to high-temperature vulcanization reversion, consisting of the following raw materials in parts by mass:

[0048]

[0049] The equilibrium vulcanization system is composed of N,N-dithiodicaprolactam, sulfur, and benzothiazole disulfide, with a mass ratio of 1:1:2.

[0050] Put the natural rubber on the open mill for thin pass plasticizing, control the temperature of the rollers below 40°C, cool and park for 12 to 24 hours after unloading; wrap the plasticized natural rubber on the rollers of the open mill according to the formula, and press Add various additives sequentially in the order of feeding, fully knead and then release the sheet. During the kneading process, control the roller temperature below 60°C; test the vulcanization characteristic curve after cooling and parking for 12 hours, and vulcanize the standard test sample on a flat vulcanizer according to the vulcanization conditions (ar...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com