A method for improving the color and flavor of dry red wine

A dry red wine and wine technology, applied in the field of winemaking science and engineering, can solve the problems of nano-bubble technology patent application and authorization, and achieve the effects of reducing the generation of undesirable sulfides, highlighting fruit aroma, and improving color and flavor

Active Publication Date: 2022-06-10

CHINA AGRI UNIV

View PDF4 Cites 0 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

At present, there is no research and application of nano-bubble technology in the field of wine, as well as the application and authorization of related patents

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment

[0035]

[0037]

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Login to View More

Abstract

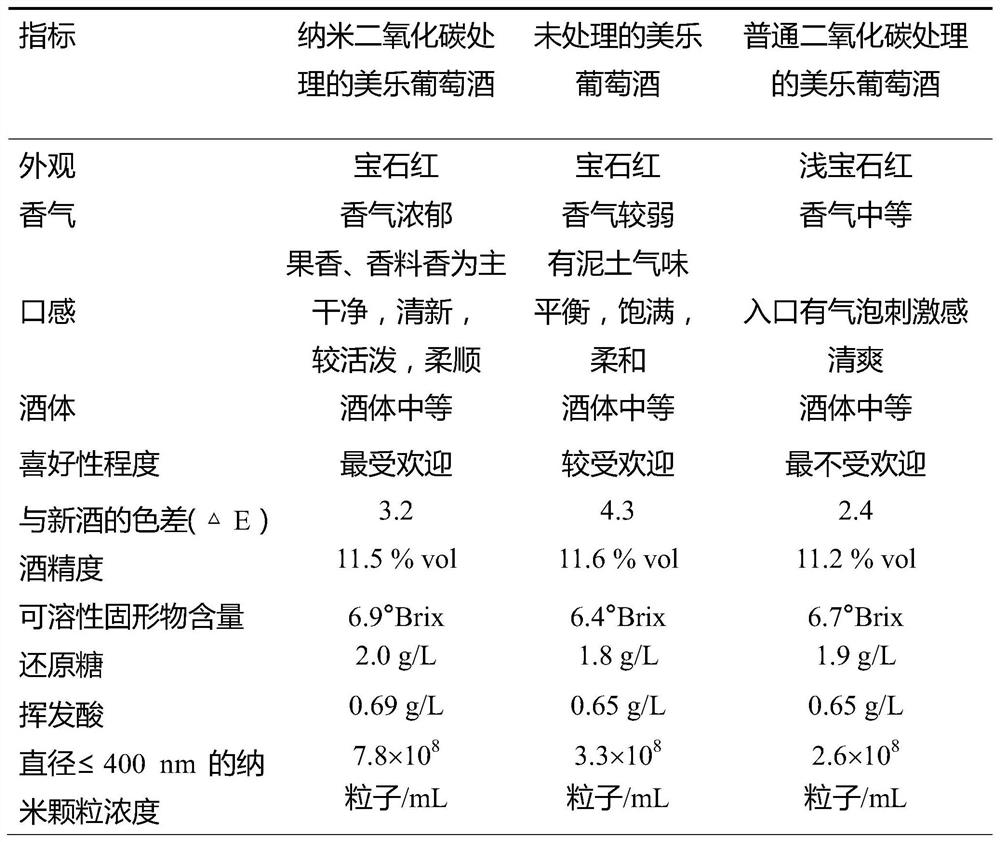

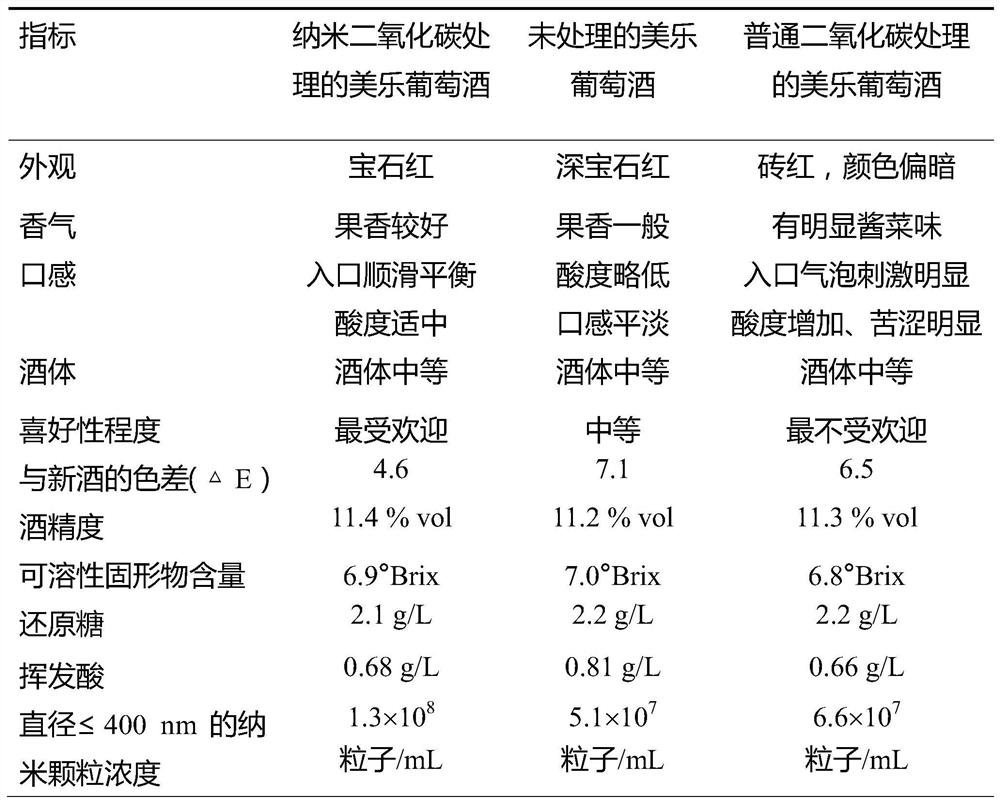

The invention relates to a method for improving the color and flavor of dry red wine. The method utilizes nano bubbles to stably regulate the aerobic environment of the dry red wine during storage, so as to achieve the purpose of improving the color and flavor of the dry red wine. The dry red wine obtained after being processed according to the method is stable ruby red, soft and moist in the mouth, rich in aroma, outstanding in fruit, moderate in acidity and delicate and balanced in taste. The sensory evaluation of wine treated with nanobubbles was better than that of untreated wine, and its advantages expanded with the prolongation of storage time.

Description

A method for improving the color and flavor of dry red wine technical field The present invention relates to winemaking science and engineering technology field, specifically, relate to a kind of improvement dry red wine color and flavor method. Background technique [0002] The flavor of wine is the result of hundreds of chemical components interacting with the human sense organs. Overall, the Portuguese There are three sources of flavor in wine: the grape itself, the fermentation process, and the aging process. In addition, when wine is bottled and stored Various chemical reactions in wine will continue to affect the changes in its flavor. Compared with berry aroma, fermentation aroma and aging aroma, Portuguese The flavor changes during wine storage are more complex. On the one hand, it can enhance the aroma and flavor of wine, and on the other hand It will produce the bad smell of "over reduction" and affect the sensory quality of the wine. Unpleasant smells...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Patents(China)

IPC IPC(8): C12G1/06C12H1/22

Inventor 陈代黄卫东战吉宬游义琳

Owner CHINA AGRI UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com