A kind of preparation method of fungal mycelia fine powder

A mycelium and fungal technology, which is applied in the field of preparation of fungal mycelium fine powder, can solve the problems of fungal fruiting body reduction in activity, increase in vacuum drying time, incomplete sterilization and disinfection, etc., and achieve good economic and social effects, Bright color and low price effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

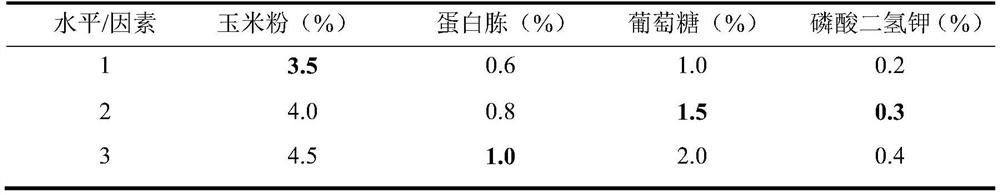

Method used

Image

Examples

Embodiment Construction

[0030] Take a kind of new strain Fibularhizoctonia sp. that the applicant discovers below as an example, introduce the preparation method of this fungus mycelia fine powder in detail:

[0031] (1) Activation of strains and preparation of mycelium mother liquor

[0032] The collected fungal sclerotia was washed several times with 1% (v / v) NaClO solution, soaked for 2-3min each time, after pouring off the waste liquid, washed off its surface residual liquid with sterile water, and then inoculated on Place the prepared slant culture medium at 24-27°C for 3-4 days. After the cultivation is complete, select the strains with better growth and store them at 4°C for later use. Wherein, the slant culture medium can be prepared by conventional methods.

[0033] Use a sterile inoculation needle to inoculate the preserved mycelium species into PDA liquid medium (agar may not be added) in an aseptic operating table, put it into a shaking table at 24-27° C. for 3-4 days, and obtain the myc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com