Silencing felt and application thereof

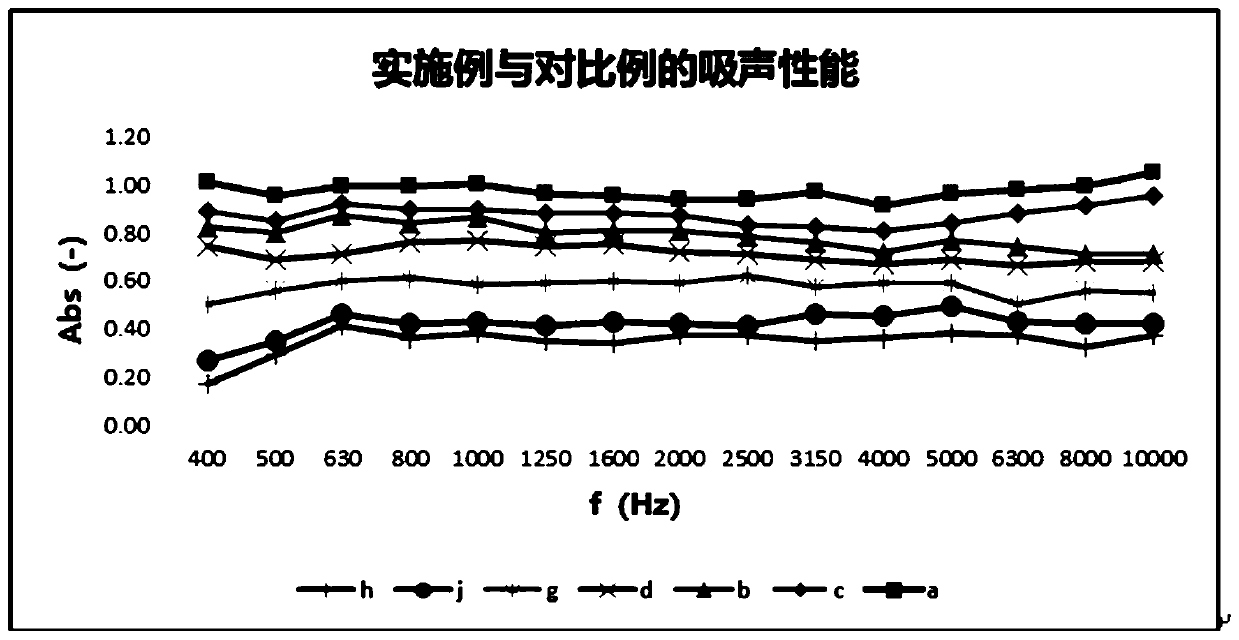

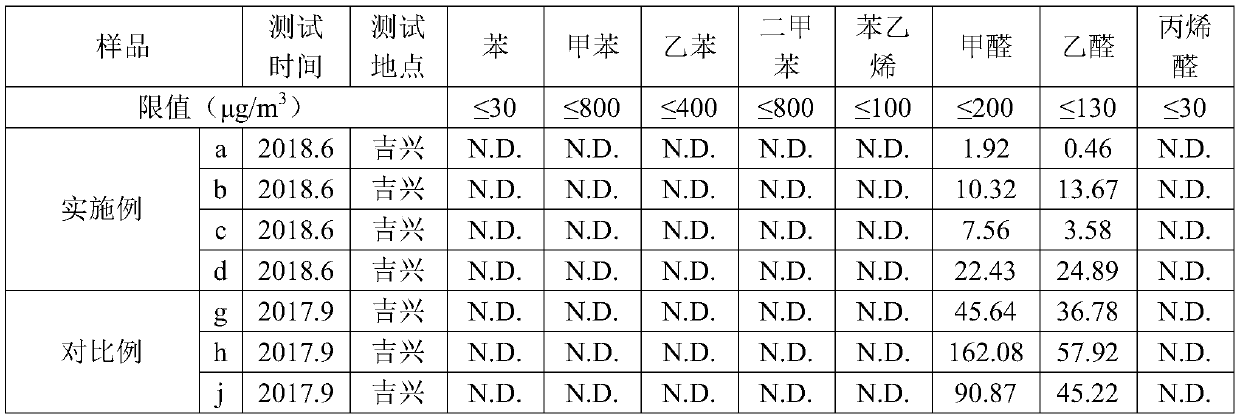

A technology of cotton fiber and low-melting fiber, which is applied in the field of sound-absorbing felt, can solve problems such as difficult to achieve sound absorption and VOC performance, unfavorable large-scale promotion, and increased cost, so as to achieve stable and controllable VOC performance and meet VOC performance requirements , Excellent sound absorption performance and VOC performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] This embodiment provides a kind of sound-absorbing felt, in terms of mass percentage, the content of recycled cotton in the sound-absorbing felt is 90%, the content of low melting point fiber is 10%, and the cotton content of recycled cotton is 100% , the area weight is 1000g / m 2 , the thickness is 15mm.

[0029] The sound-absorbing felt obtained in this example is designated as sample a.

Embodiment 2

[0031] This embodiment provides a kind of anechoic felt, in terms of mass percentage, the content of recycled cotton in the described anechoic felt is 90%, the content of low melting point fiber is 10%, and the cotton content of recycled cotton is 90% , the area weight is 1000g / m 2 , the thickness is 15mm.

[0032] The sound-absorbing felt obtained in this example is designated as sample b.

Embodiment 3

[0034] This embodiment provides a kind of anechoic felt, in terms of mass percentage, the content of recycled cotton in the described anechoic felt is 85%, the content of low melting point fiber is 15%, and the cotton content of recycled cotton is 100% , the area weight is 1000g / m 2 , the thickness is 15mm.

[0035] The sound-absorbing felt obtained in this example is designated as sample c.

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| quality score | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com