Hot rolled alloy steel flaw detection device

A flaw detection device, alloy steel technology, applied in measuring devices, using sound waves/ultrasonic waves/infrasonic waves to analyze solids, using sound waves/ultrasonic waves/infrasonic waves for material analysis, etc., to achieve the effect of fast air flow

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The following will clearly and completely describe the technical solutions in the embodiments of the present invention with reference to the accompanying drawings in the embodiments of the present invention. Obviously, the described embodiments are only some, not all, embodiments of the present invention.

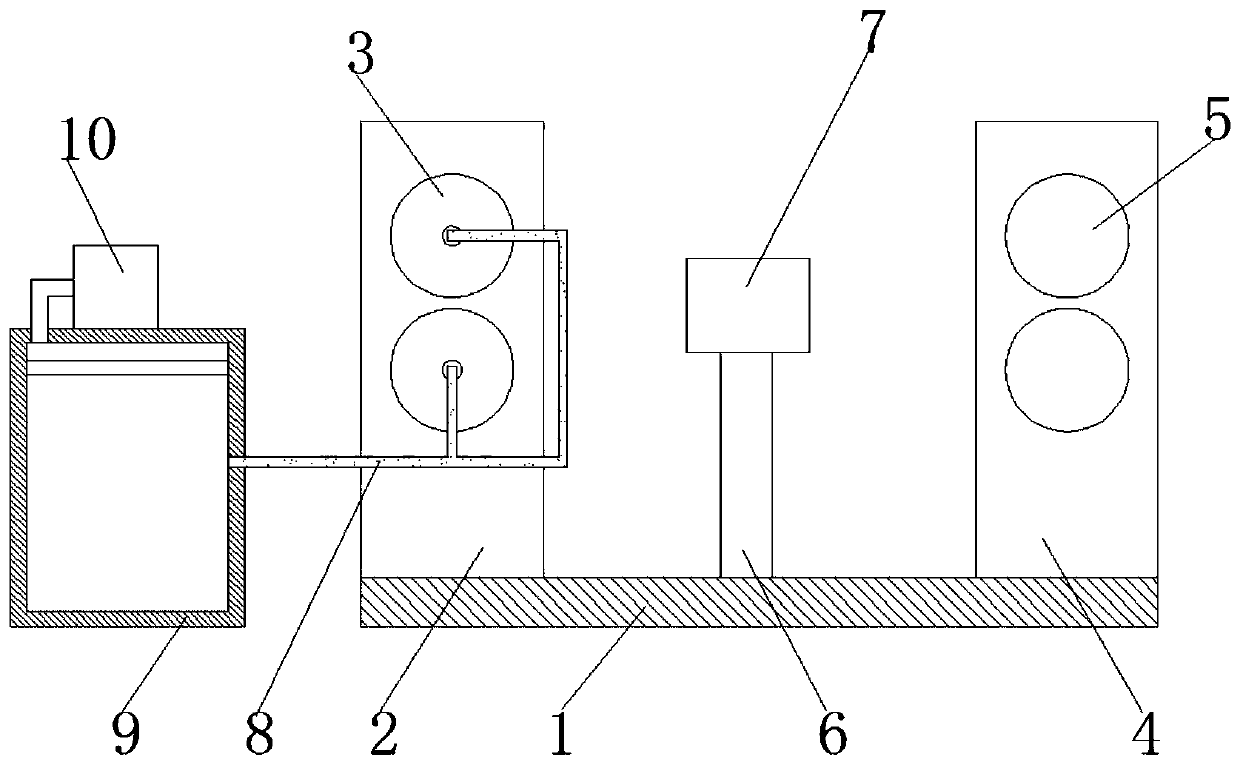

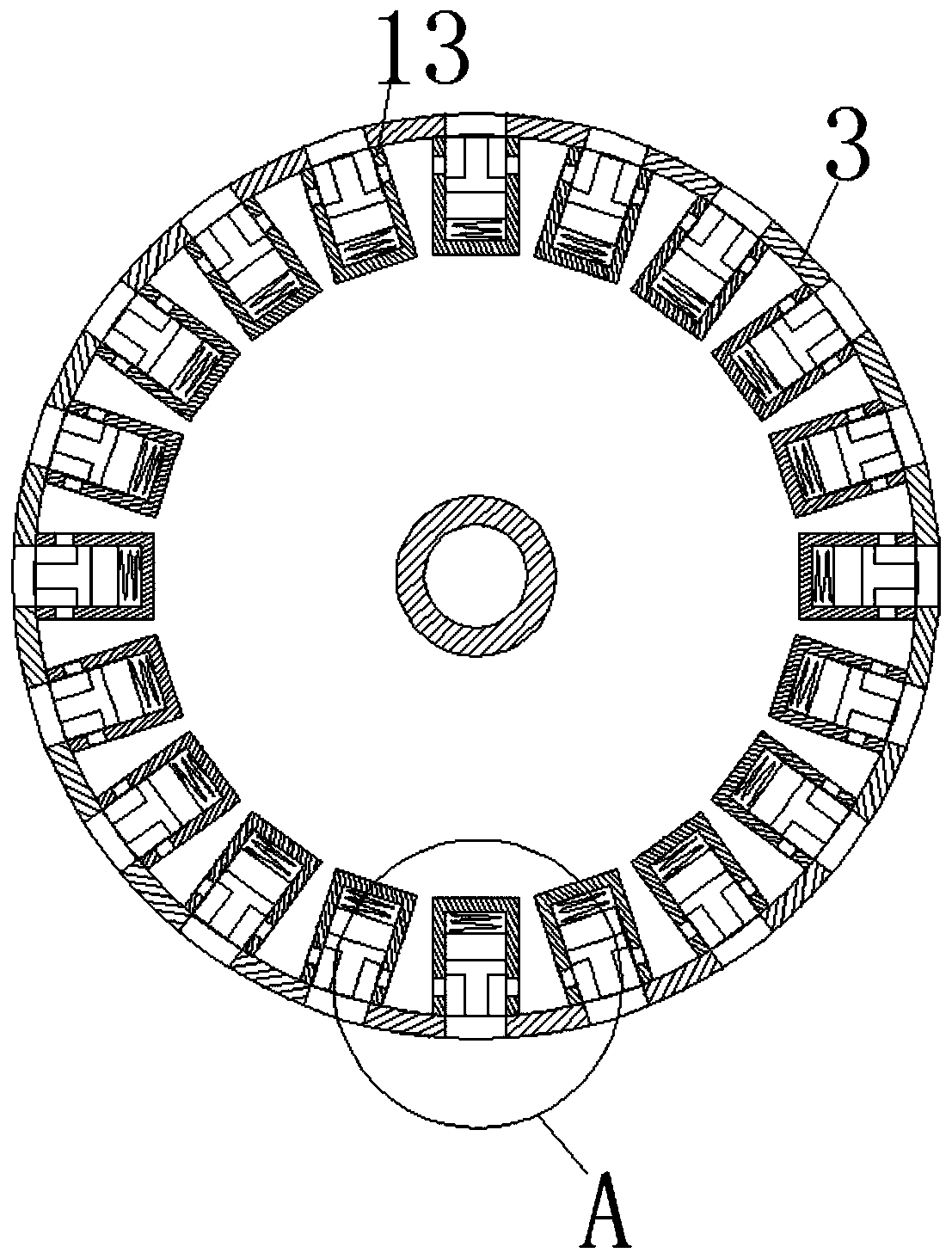

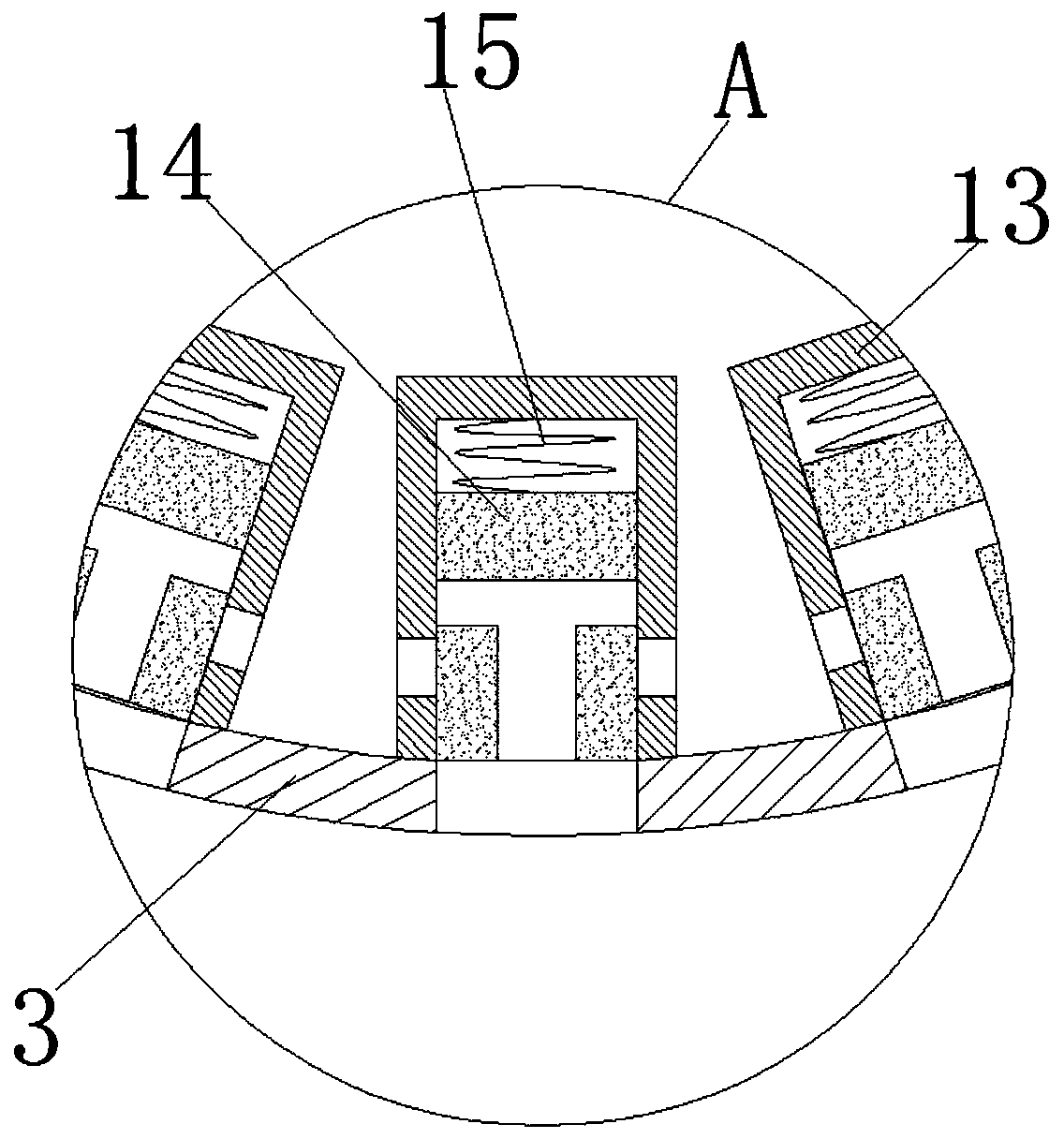

[0024] refer to Figure 1-6 , a flaw detection device for hot-rolled alloy steel, including a base 1 and an ultrasonic flaw detector 7, the upper end of the base 1 is provided with a first support plate 2, a second support plate 4 and a support rod 6, and the first support plate 2 and The second support plate 4 is on the same plane, and the support rod 6 is located between the first support plate 2 and the second support plate 4, and the first drive plate 3 is arranged on the first support plate 2, The number of the first driving disc 3 is two, and there is a gap between the first driving discs 3, the first driving disc 3 is installed on the first support plate 2 thr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com