S-shaped turbulent flow structure for large-air-volume surfacing type plate heat exchanger

A technology of plate heat exchanger and large air volume, which is applied in the direction of heat exchanger shell, heat exchange equipment, lighting and heating equipment, etc. Large heat exchange area and the effect of improving heat exchange efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The technical solutions of the present invention will be described in connection with the examples and the drawings, and the description is clearly, and the embodiments described are intended, and the described embodiments are the embodiments of the present invention, not all of the embodiments.

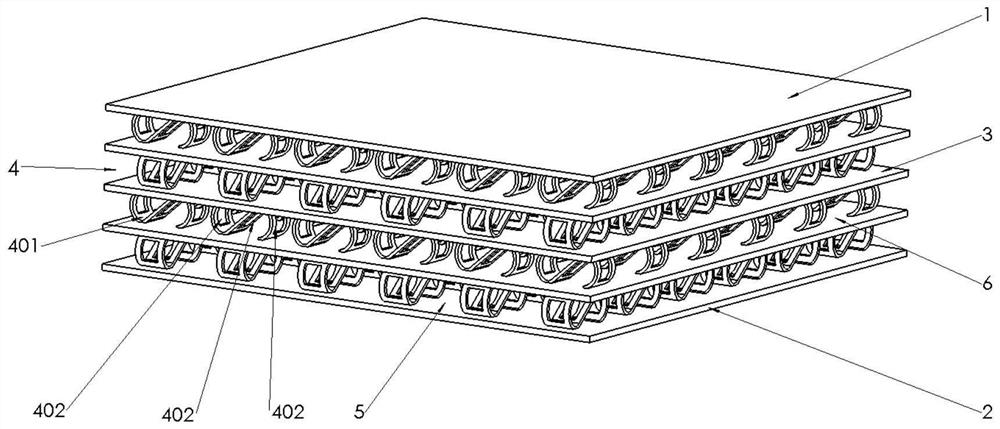

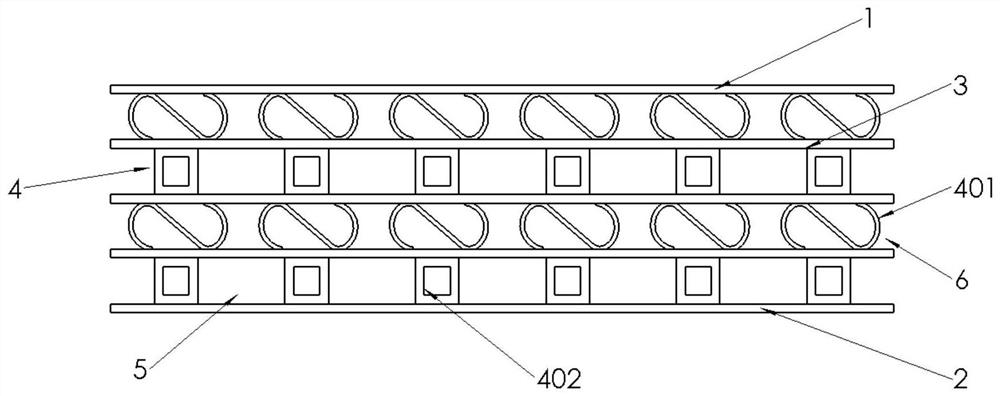

[0027] Refer figure 1 , figure 2 with image 3 A S-shaped spoiler structure for a large wind quantity surfacing plate heat exchanger, including the upper layer plate 1, the lower layer plate 2, and has three medium separator 3 between the upper layer plate 1 and the lower plate 2. Between the upper plate 1 and the middle partition 3, between the adjacent spacers 3, there is a S-type insert 4 between the middle partition plate 3 and the lower layer plate 2, the cooling airflow 5 and the high temperature air flow 6 in the S type In-inventory 4 blended.

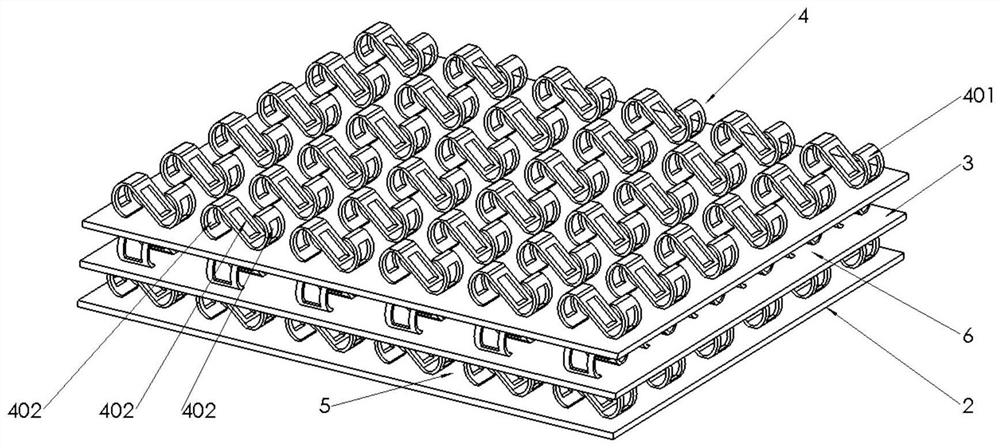

[0028] Refer Figure 4 , Figure 5 with Figure 6 The S-shaped insert 4 is arranged by a S-band 401 by a compliant or misalignment, an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com