A kind of citrus flavor additive containing polymethoxyflavone and preparation method thereof

A technology for polymethoxyflavones and flavor additives is applied in the field of citrus flavor additives containing polymethoxyflavones and the preparation thereof, which can solve the problems of complicated steps, expensive equipment, loss of flavor substances, and the like, and achieves that the method is simple in operation and good in quality. Economic benefits and the effect of realizing industrialization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

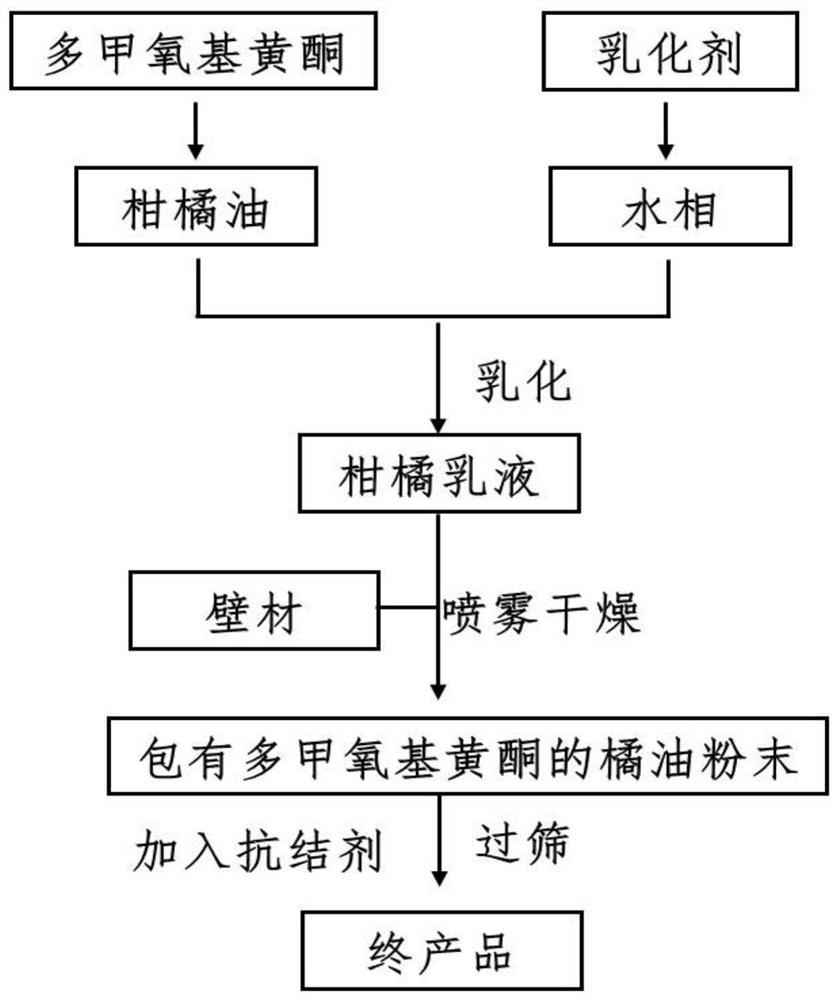

[0026] In the method of the present disclosure, in order to make the citrus flavor in the citrus flavor additives obvious and to keep the food with aroma, polymethoxylated flavones can be used as the core material and citrus oil as the oil phase, and the citrus oil and polymethoxylated flavonoids can be used as the oil phase. The oil phase mixture of flavonoids is mixed with water and emulsifier for initial embedding to obtain citrus oil emulsion. Wherein the operation method and the condition of mixing and emulsifying the oil phase and the water phase can be conventional in the art. In one embodiment of the present disclosure, the preparation method of the citrus oil emulsion can include: adding polymethoxylated flavones in a required amount to Mix evenly in citrus oil, the mixing conditions may include: the temperature is 80-120°C, the stirring time is 0.5-4h; the emulsifier and water are mixed and stirred evenly, the mixing conditions may include: the temperature is 10-30°C,...

Embodiment 1

[0038] a. Weigh 50g of maltodextrin, add distilled water to make up to 100ml, heat and stir in a 30°C water bath until the maltodextrin is completely dissolved, and the stirring time is 10 minutes to make a wall material with a solid content of 50%. solution;

[0039] b. Weigh 10mg of nobiletin into 5g of sweet orange oil, and stir in a 90°C water bath for 2 hours while heating; use high-methoxyl citrus pectin as an emulsifier, weigh 1g to 94g of distilled water, and stir at room temperature 10h until the citrus pectin is completely dissolved; the citrus pectin solution is used as the water phase, and the sweet orange oil coated with nobiletin is used as the oil phase, and the oil phase is slowly added to the water phase, and sheared at a high speed of 10000r / min for 3min Coarse milk was obtained, and the sweet orange oil emulsion wrapped with nobiletin was obtained after 3 times of high-pressure homogeneous circulation under 720MPa pressure;

[0040] C, the maltodextrin wall...

Embodiment 2

[0045] a. Weigh 70g of chitosan, add distilled water to make up to 100ml, heat and stir in a 30°C water bath until the chitosan is completely dissolved, and the stirring time is 15 minutes to make a wall material with a solid content of 70%. solution;

[0046] b. Weigh 15mg of tangeretin into 5g of sweet orange oil, stir in a 90°C water bath for 2 hours while heating; use high methoxyl citrus pectin as emulsifier, weigh 1g to 94g of distilled water, and stir at room temperature 10h until the citrus pectin is completely dissolved; the citrus pectin solution is used as the water phase, and the sweet orange oil coated with tangeretin is used as the oil phase, and the oil phase is slowly added to the water phase, and sheared at a high speed at 9000r / min Coarse milk was prepared in 3 minutes, and then the sweet orange oil emulsion wrapped with tangeretin was obtained after 3 times of high-pressure homogeneous circulation at a pressure of 700 MPa;

[0047] C, the chitosan wall mate...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com